A Prediction Method for Cutting Performance of Shield Tunneling Cutters in Partitions

A cutting performance, shield cutter head technology, applied in design optimization/simulation, special data processing applications, etc., can solve the problems of limited number of inspection tools, multi-sample data, and inability to assess tool wear in formation in advance, etc., to achieve partitioning The effect of monitoring, improving the degree of discrimination, and novel entry points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in combination with specific embodiments.

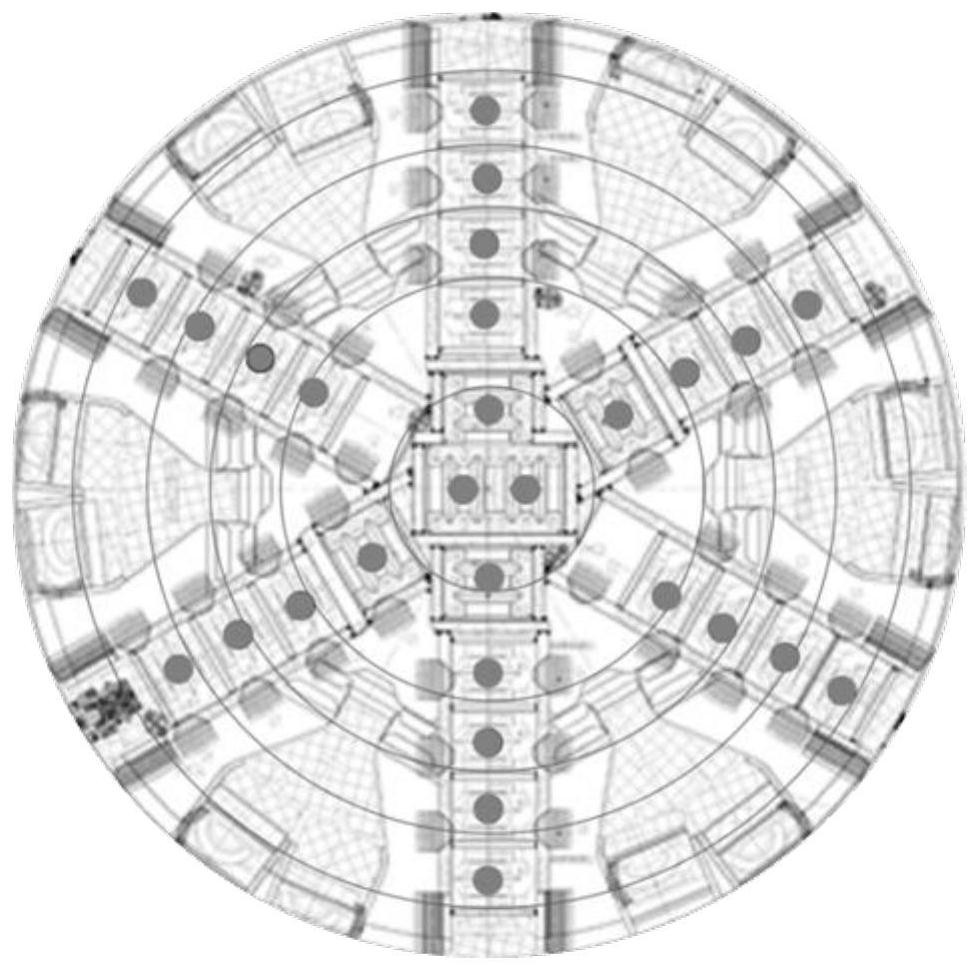

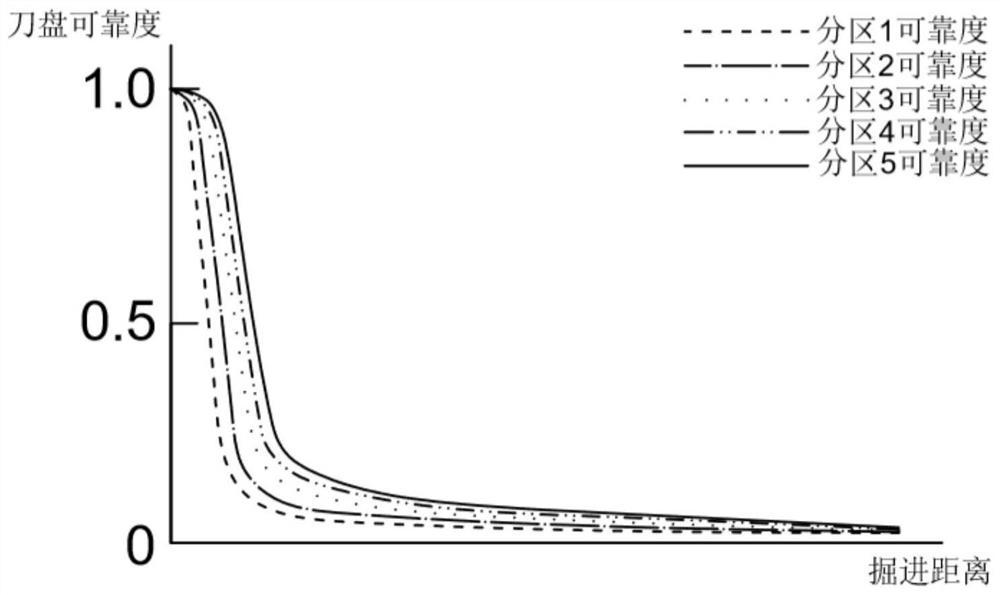

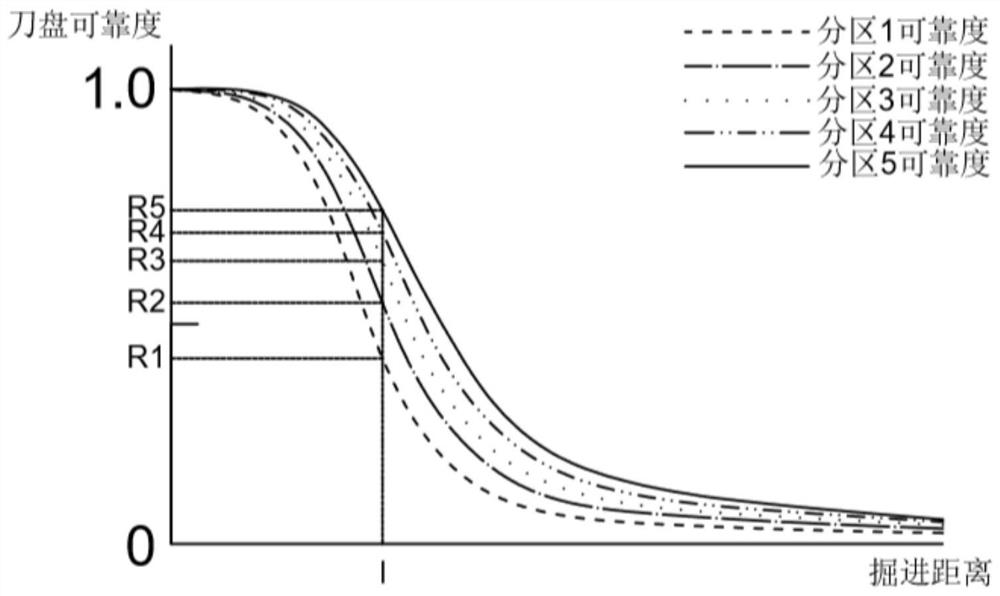

[0051] see Figure 1-Figure 3 , a method for predicting the cutting performance of a shield cutterhead tool partition, comprising the following steps:

[0052] Step (1): First discuss various environmental factors of shield tunneling, including two major indicators: stratum abrasiveness and human factors. Each indicator is scored, and each is assigned a weight according to its impact on tool wear. Item scores, and finally calculate an environmental assessment value S that considers various environmental factors of shield tunneling, as detailed below:

[0053] a. Formation abrasiveness

[0054] The rock abrasiveness index (RAI) proposed by Plinninger in 2002 is used to characterize the abrasiveness of the formation to the cutterhead. This index takes into account the unconfined uniaxial compressive strength (UCS) and equivalent quartz content (EQC) of the formation rock ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com