A magnetically fixed ground wire clamp

A technology of grounding wire clips and grounding wires, which is applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of inability to ensure the complete connection of grounding wires, long operation time, and potential safety hazards, and achieves simple structure, convenient operation, and security safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

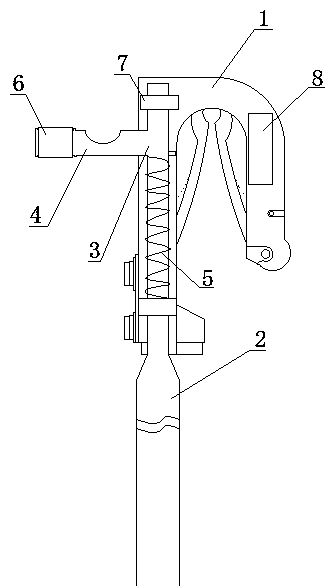

[0019] Such as figure 1 As shown, this embodiment provides a magnetically fixed ground wire clamp, including a jaw-type ground wire clamp 1 and an insulating operating rod 2 . The insulating operating rod 2 is provided with a clamping section 3 , and the insulating operating rod 2 is rotatably connected to the ground wire chuck 1 through the clamping segment 3 .

[0020] Specifically, the clamping section 3 is provided with a crossbar 4 made of metal, the length of the crossbar 4 is greater than the opening of the ground wire clamp 1, and the outermost end of the crossbar 4 is provided with a metal sleeve 6, and the metal sleeve 6 and the crossbar 4 The rotation is fixed, and the middle section of the cross bar 4 also has a recessed position, and the direction of the recessed position is vertically upward, effectively increasing the contact area with the cable.

[0021] In addition, the ground wire clamp 1 is divided into a fixed end and an open end, and the clamping section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com