Centralized switching cabinet used for intelligent substation analog sampling secondary equipment prefabricated cabinet

A technology of intelligent substation and secondary equipment, applied in substation/distribution device housing, electrical components, busbar/line layout, etc., can solve problems such as unfavorable long-term operation, inability to do, and inability to install and maintain prefabricated cables inside. Achieve the effect of facilitating cable routing and later maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

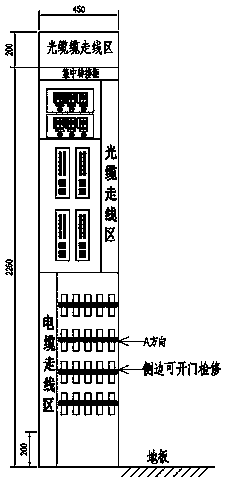

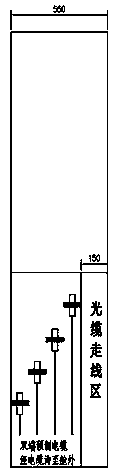

[0022] The invention discloses a centralized transfer cabinet used in a prefabricated cabin of a secondary equipment for analog quantity sampling in an intelligent substation, and is a centralized switch cabinet used in a prefabricated cabin for a secondary equipment for analog quantity sampling in an intelligent substation. The technical scheme of the present invention adopts functional divisions, which are composed of three parts: DC air-opening area, optical cable transfer area, and cable transfer area. It is more convenient to use.

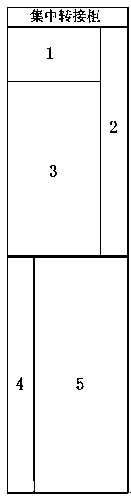

[0023] see figure 1 , a structural schematic diagram of a centralized transfer cabinet for the prefabricated cabin of the analog quantity sampling secondary equipment of the intelligent substation provided by the present invention, the centralized transfer cabinet includes a DC open area 1, an optical cable rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com