Method for machining workpieces and grinding machine

A technology for grinding machines and workpieces, which is applied to machine tools, machine control programs of grinding machines, grinding machines, and grinding processing fields for shaft components used in vehicle drive devices to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

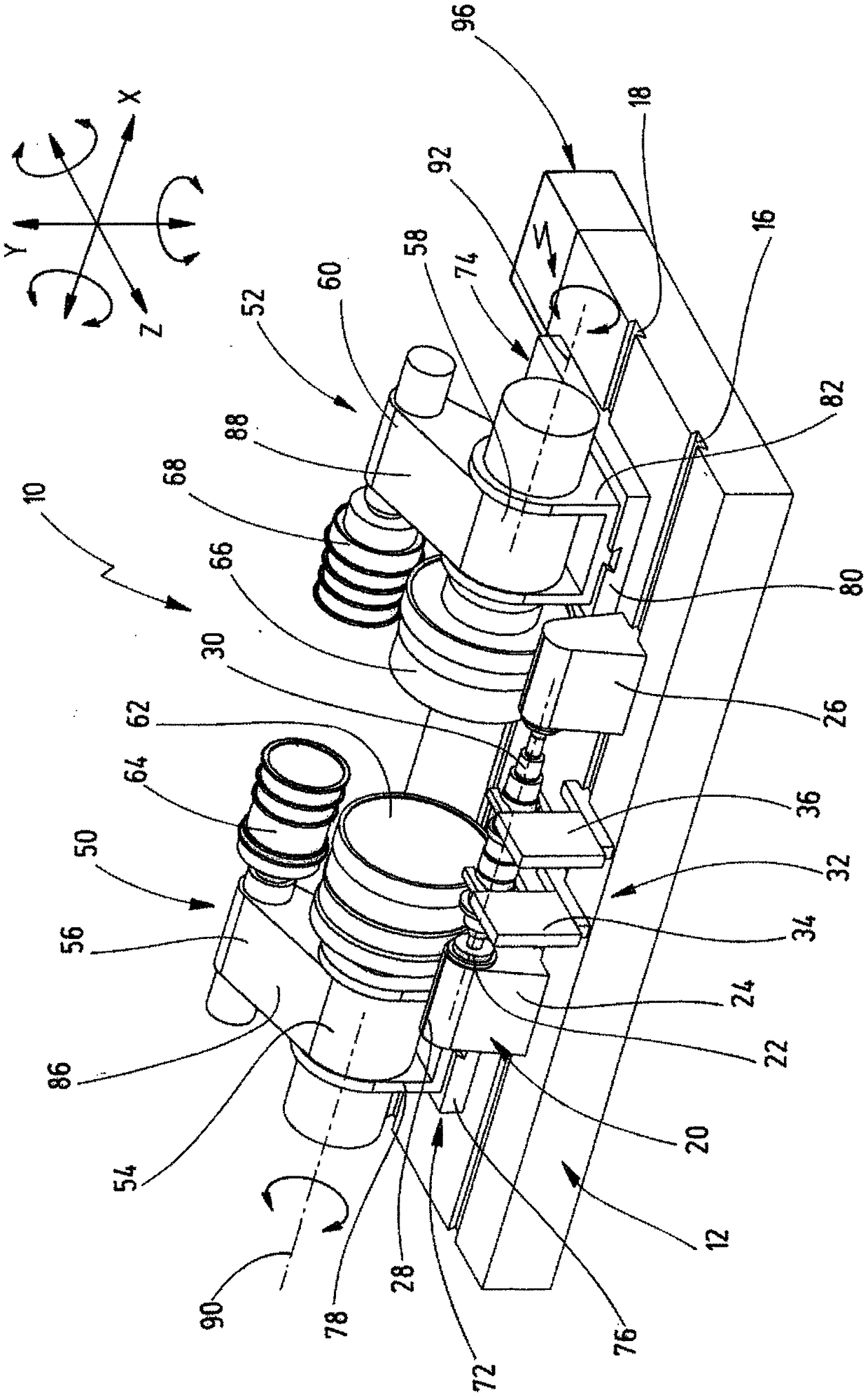

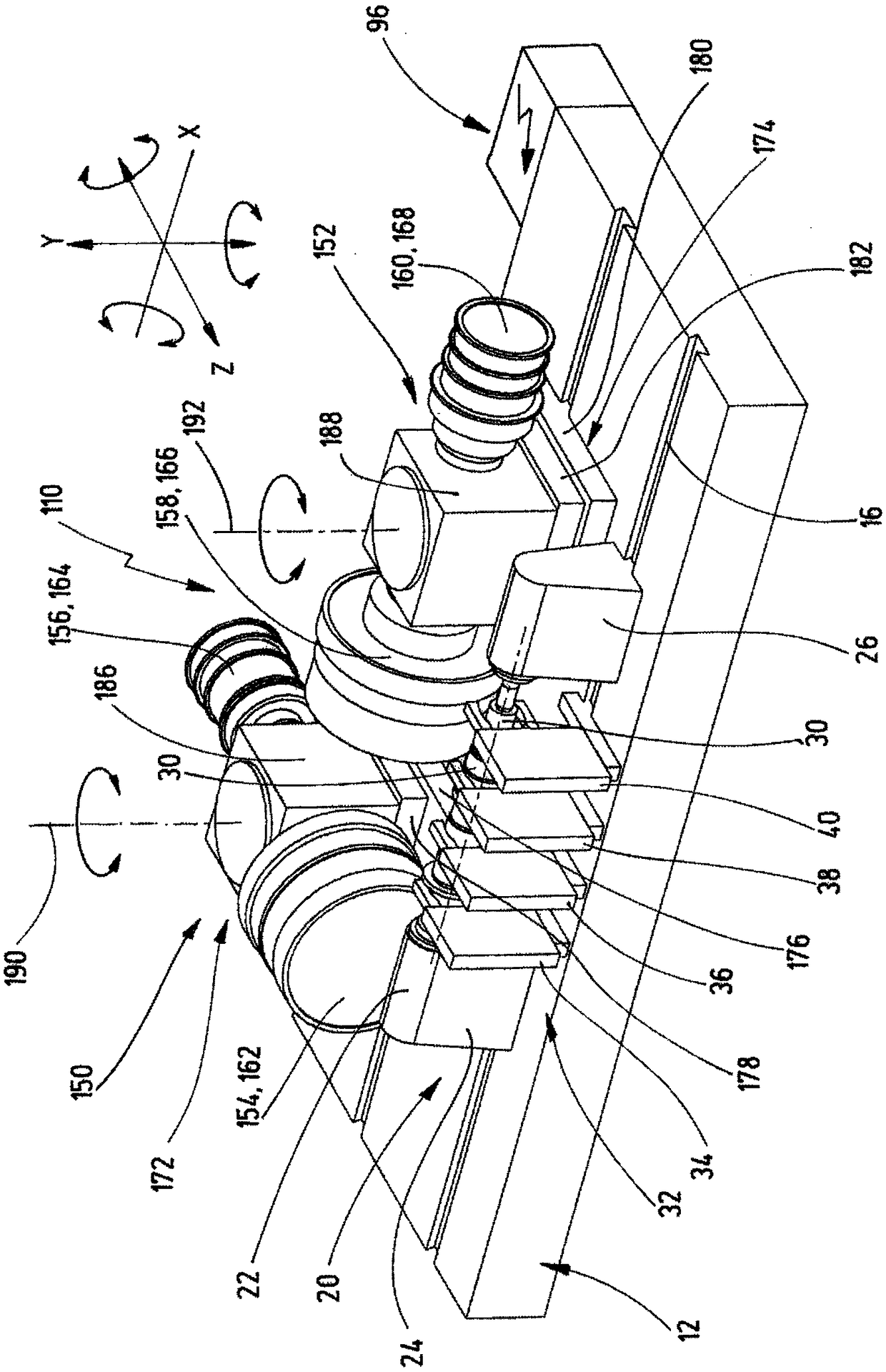

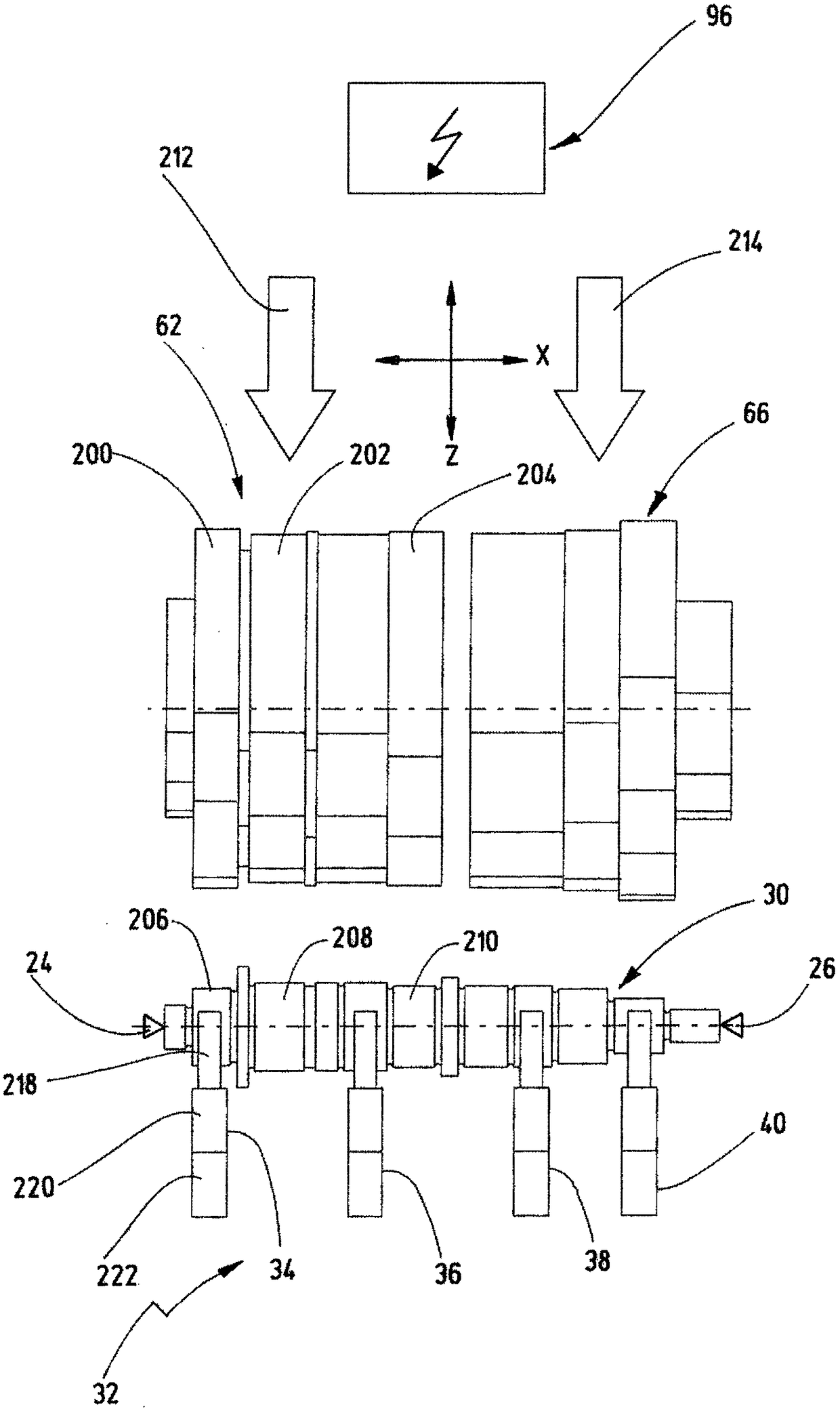

[0087] figure 1 A schematic perspective view of a power tool 10 , which is designed as a grinding machine, is shown.

[0088] The grinding machine 10 has a machine tool 12 which can also be referred to as a machine frame. Guides 16 , 18 are formed on the machine tool 12 . Components of the grinding machine 10 can be moved along the guides 16 , 18 and optionally fixedly arranged.

[0089] In at least some of the figures shown here, for purposes of illustration, coordinate systems are shown. Usually, the longitudinal direction is marked with an X. The horizontal direction is marked with Z. Vertically marked with Y. In this way, three translational or rectilinear axes X, Y and Z are defined. Respective rotations about axes X, Y and Z define respective axes of rotation. It goes without saying that, for illustration purposes, alternative coordinate systems, such as a machine coordinate system and / or a workpiece coordinate system, are also conceivable. The required imaginary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com