Inflatable structure welding device

An inflatable structure and welding technology, which is applied to hollow objects, household appliances, and other household appliances, can solve the problems of inapplicable heat welding, etc., and achieve the effect of preventing contact and preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the pneumatic structure welding device of the present invention will be described in detail with reference to the accompanying drawings.

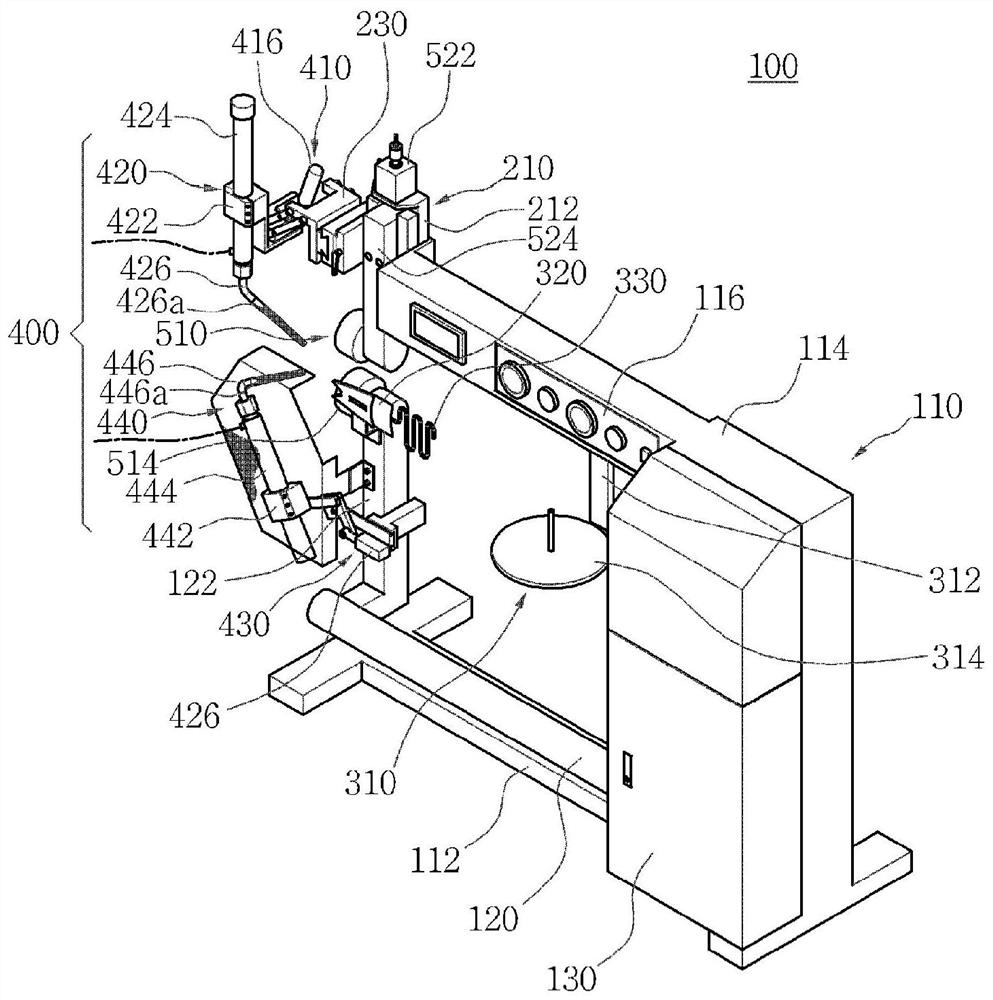

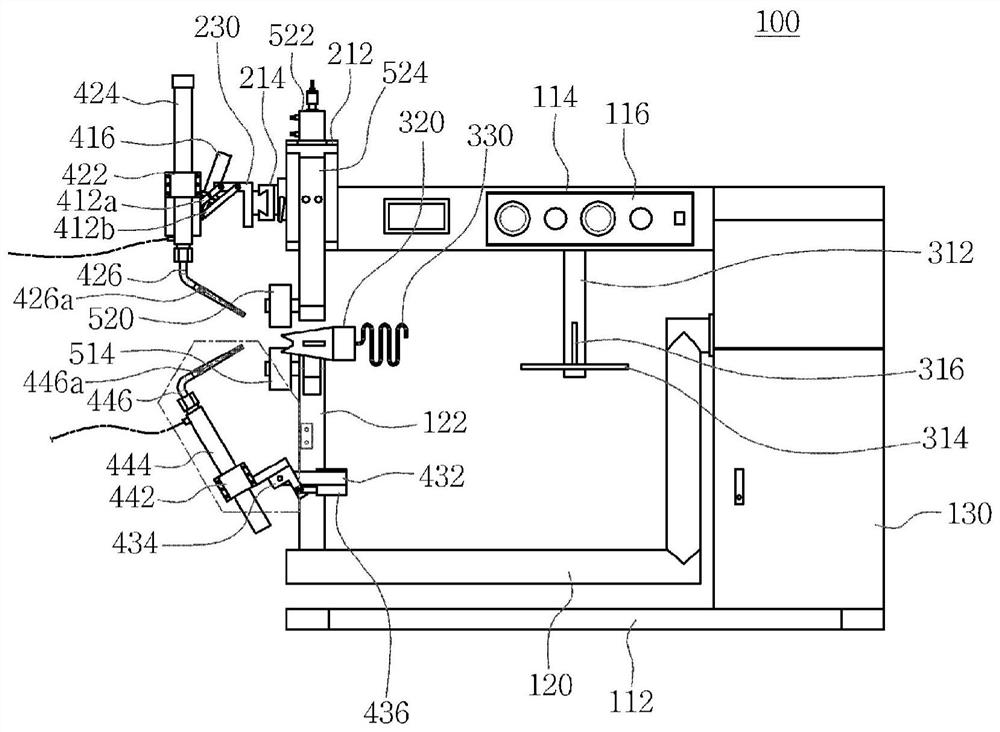

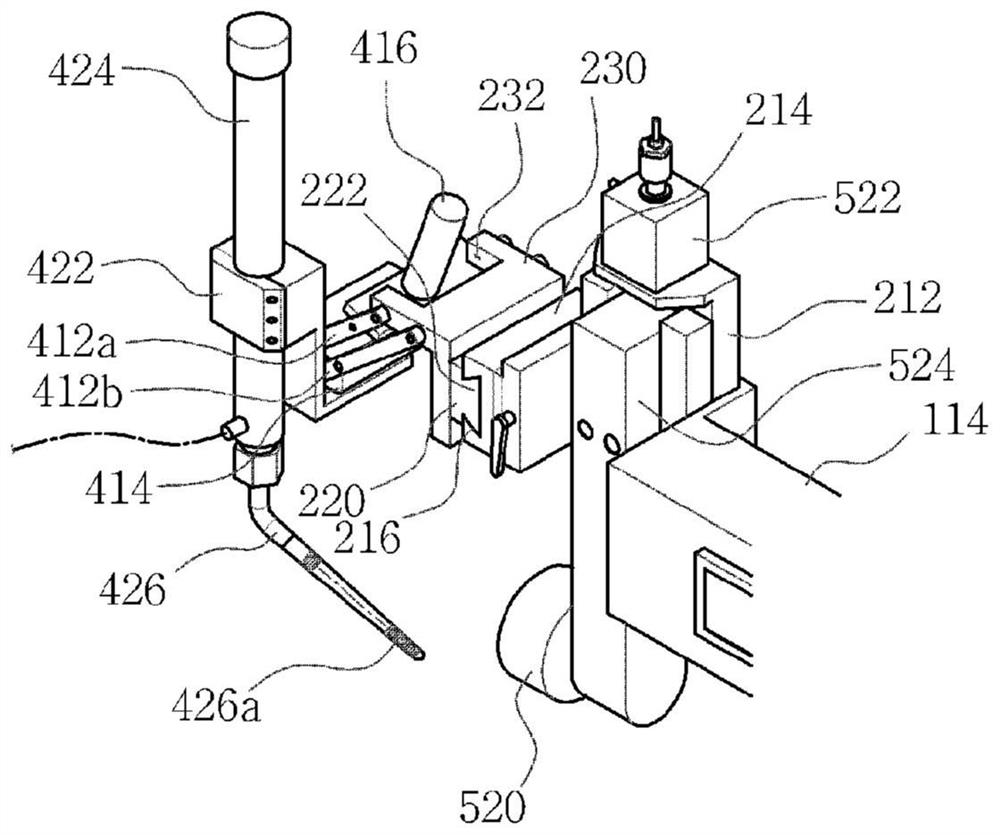

[0045] figure 1 To show a perspective view of the inflatable structure welding device of the present invention, figure 2 In order to show the front view of the inflatable structure welding device of the present invention, Figure 3a and Figure 3b For showing the figure of the connection part of the present invention, Figure 4a and Figure 4b It is a figure showing the edge member supply part of the present invention, Figure 5a to Figure 5d For showing the figure of the hot air injection unit of the present invention, Figure 6 It is a figure which shows the pressurization part of this invention.

[0046] Such as Figure 1 to Figure 6 As shown, the inflatable structure welding device 100 of the present invention includes: a body part 110; a connecting part 210, which is arranged on the above-mentioned body part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com