Drying device of ceramic 3D printer

A technology of 3D printers and drying devices, which is applied to ceramic forming machines, manufacturing tools, additive processing, etc. It can solve the problems of complex operation, lower production efficiency, and inability to guarantee the temperature of glue output, so as to achieve simple and convenient operation and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

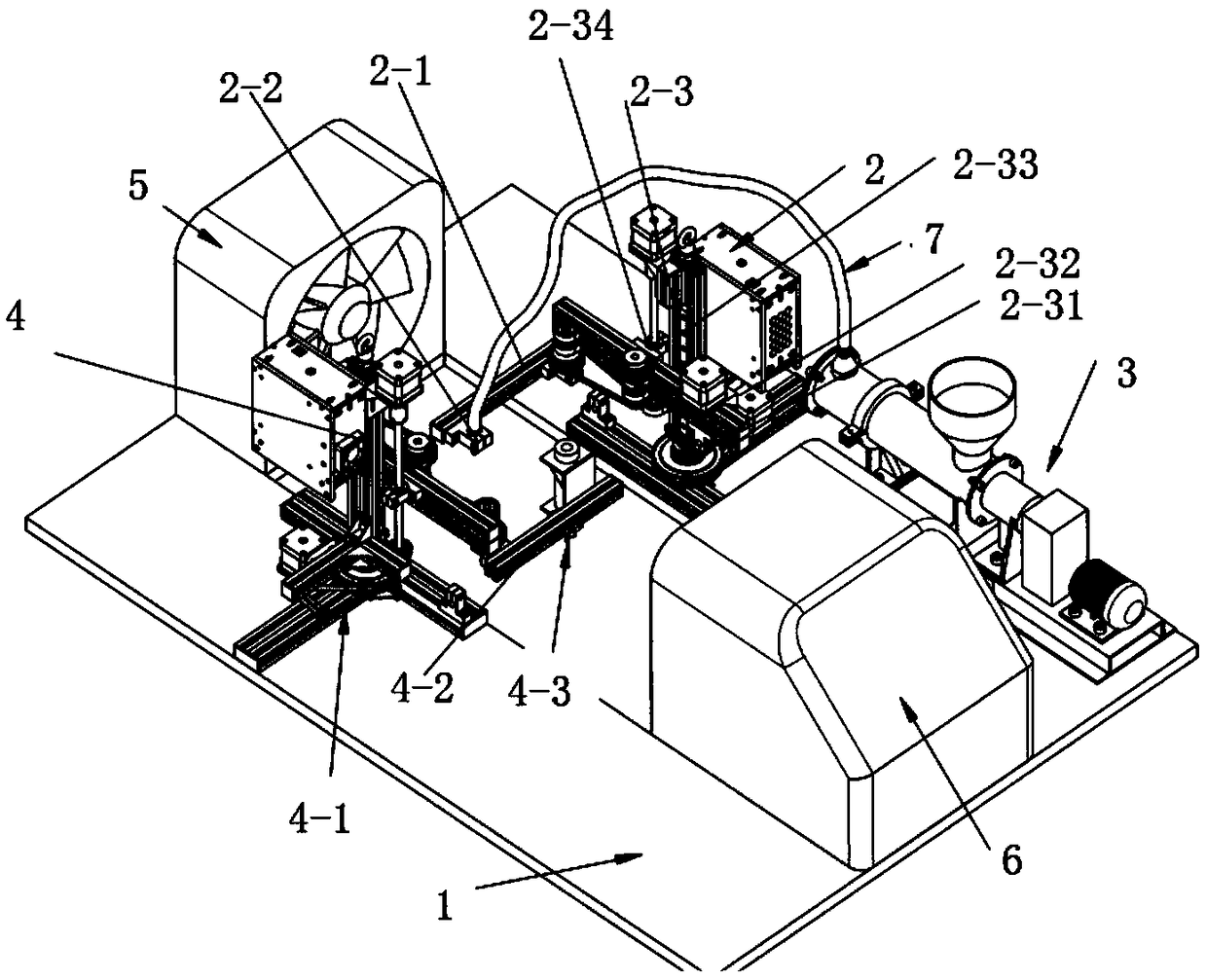

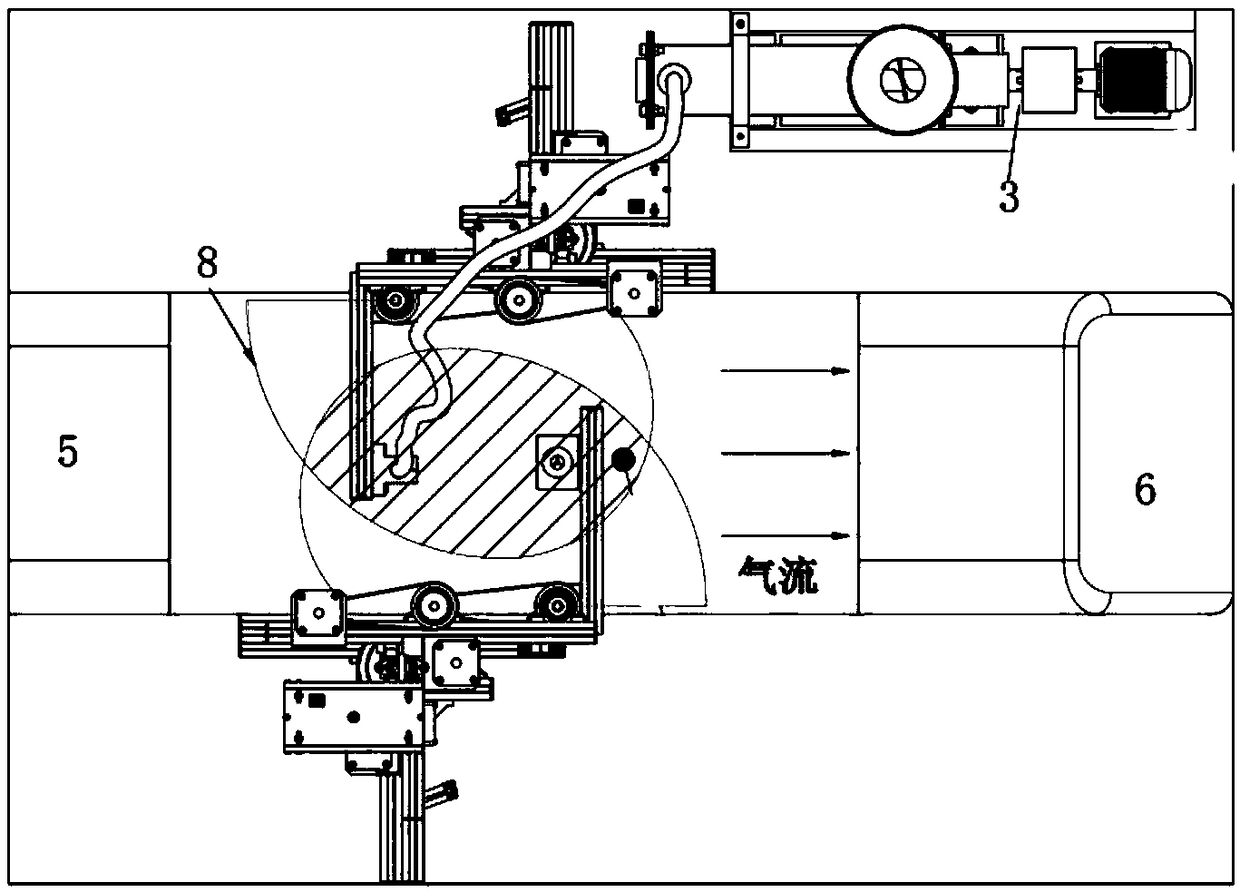

[0021] Such as Figure 1-Figure 2 As shown, the present invention is a drying device for a ceramic 3D printer, wherein the ceramic 3D printer includes a frame 1 and a working area set on it, a 3D printing device 2, a feeding device 3, and a mechanical arm milling cutter device 4 , a drying device 5 and a waste recycling device 6. The 3D printing device includes a printing arm 2-1, a printing nozzle 2-2, and a position adjustment mechanism 2-3. The printing arm is arranged on the position adjustment mechanism 1, and the printing nozzle is connected to the feeding device; the mechanical arm type milling cutter device 4 is arranged outside the 3D printing device, including a position adjustment mechanism 2 4-1, a milling cutter arm 4-2 and a milling cutter clamp 4-3 arranged on it; the printing arm and the milling cutter arm are respectively Extending to the working area, switching work; the drying device is set outside the working area, and the drying process is carried out duri...

Embodiment 2

[0026] In this embodiment, the feeding device is driven by air pressure, and includes a pump and a feeding tube connected between the pump and the printing nozzle.

[0027] Compared with the prior art, the present invention adopts a ceramic 3D printing device mainly composed of a 3D printing device, a feeding device, a mechanical arm milling cutter device, a drying device and a waste recycling device. The 3D printing device includes a printing arm, a printing nozzle , Position adjustment mechanism 1, the printing arm is set on the position adjustment mechanism 1, and the printing nozzle is connected to the feeding device; the mechanical arm type milling cutter device is set outside the 3D printing device, including the position adjustment mechanism 2, the milling cutter arm and the set on it The milling cutter fixture; the printing arm and the milling cutter arm are respectively extended to the working area, and the work is switched; the drying device is set outside the working...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap