Processing mould for bottled product packaging box with environment-friendly function

A technology for product packaging and processing molds, which is applied in the direction of transportation and packaging, containers for preventing mechanical damage, containers, etc. It can solve the problems of difficult processing of cardboard materials, difficult decomposition of white foam plastics, and environmental pollution, and achieves low cost and simple structure , the effect of light gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now in conjunction with accompanying drawing, the present invention will be further described:

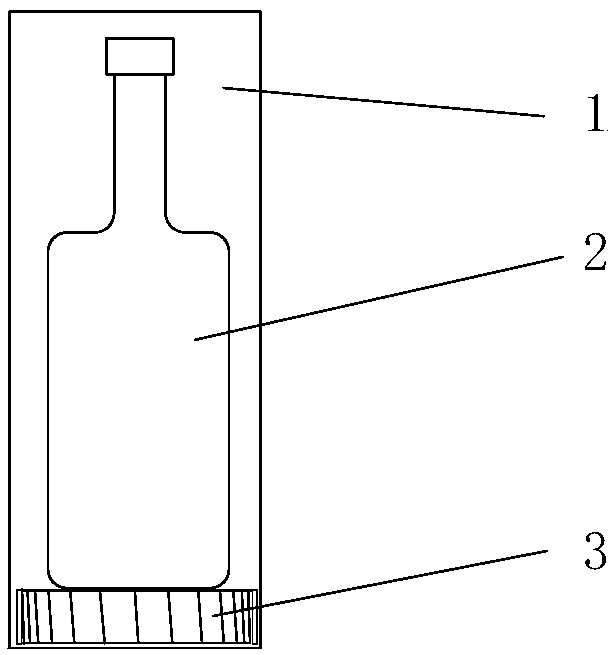

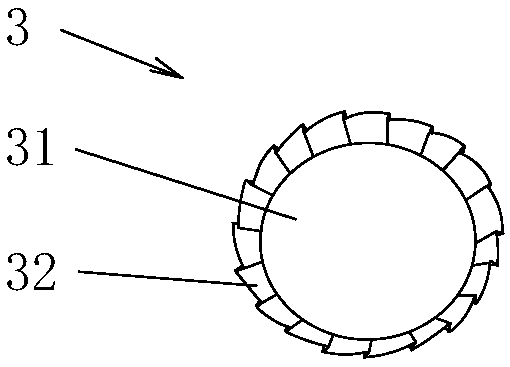

[0033] As shown in the figure, a packaging box for bottled products with an environmental protection function includes: an outer box body 1, and a shockproof pad 3 for a bottled product 2 is installed on the bottom of the outer box body 1. The feature is that the shockproof pad 3 is made of a circular The cardboard is folded to form a top surface 31 and a side surface 32, the top surface 31 is a circular plane, and the side surfaces 32 are connected by a plurality of pleated surfaces to form a circumferential surface.

[0034] The circular plane 31 has a diameter of 5-10 cm and a height of 1-1.5 cm.

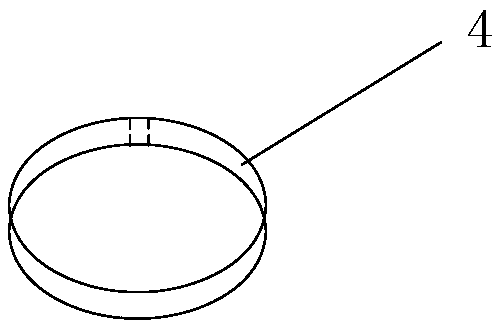

[0035] The anti-vibration pad 3 is covered with an annular cardboard ring 4, which is tightly sleeved on the outside of the anti-vibration pad 1, and the height of the annular cardboard ring 4 is close to that of the anti-vibration pad 3.

[0036] The ring-shaped cardboard rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com