A buffer frame that transports cement downwards through a spring structure

A technology of spring structure and buffer machine, which is applied in the direction of transportation and packaging, conveyor objects, support frames, etc., can solve the problems of difficult control of equipment cost, large space occupation, long transportation distance, etc., to reduce acceleration, ensure smooth sliding, The effect of reducing the tilt angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

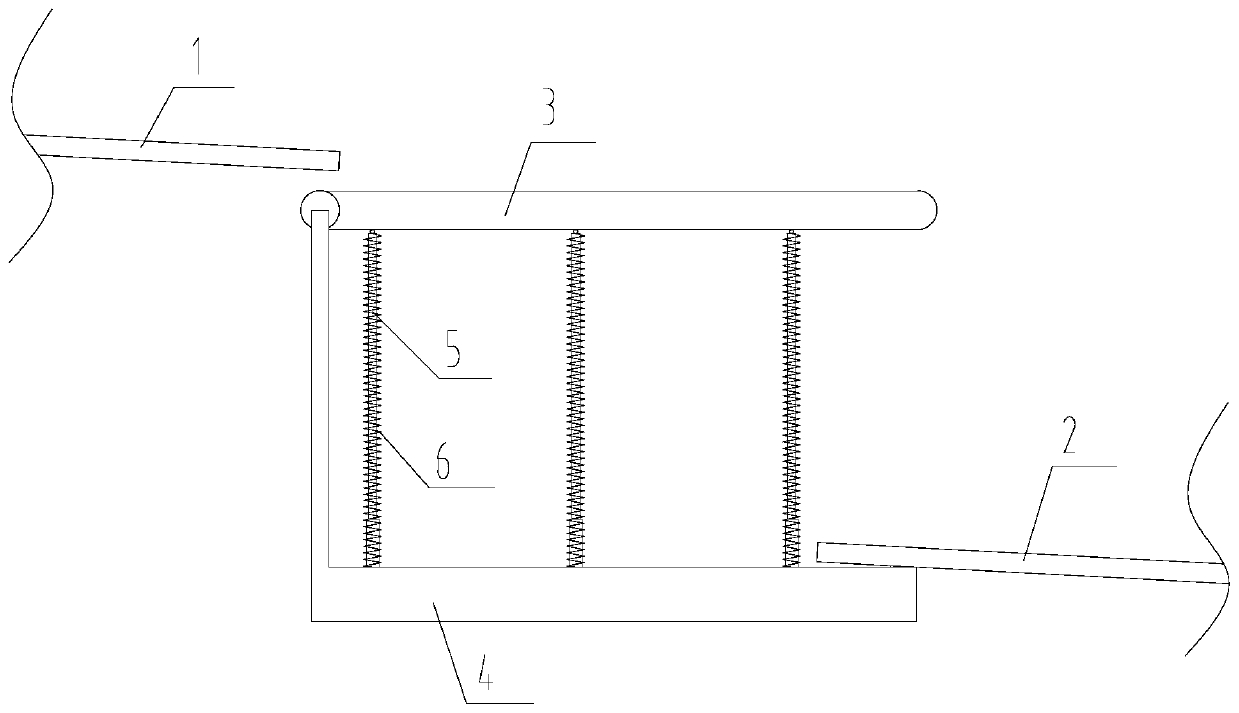

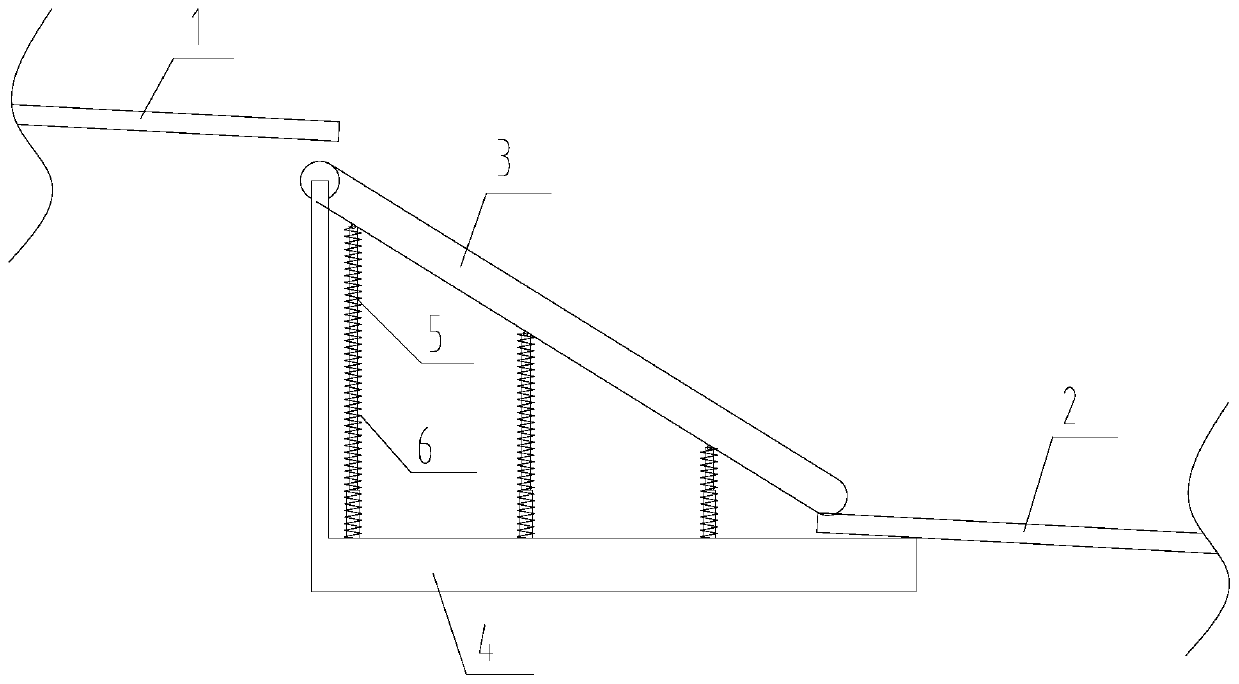

[0018] refer to figure 1 , the present invention proposes a buffer frame for conveying cement downward through a spring structure, comprising: a first conveying track 1 , a second conveying track 2 , a turntable 3 , a support frame 4 and a plurality of telescopic rods 5 .

[0019] The first end of the turntable 3 is hinged to the support frame 4, and the turntable 3 is installed to rotate in the vertical direction. A plurality of telescopic rods 5 are installed vertically on the support frame 4, the lower ends of the telescopic rods 5 are slidably connected with the support frame 4, and the upper ends of the telescopic rods 5 are hingedly connected with the lower surface of the turntable 3. Springs 6 are sheathed on each telescopic rod 5, and in a natural state, the first end of the turntable 3 is higher than the second end or is located on the same level as the second end.

[0020] During the rotation process of the turntable 3, there are a first position state and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com