Gear carburization process and application thereof

A gear and carburizing technology, which is applied in the field of heat treatment, can solve the problems of cumbersome process and achieve the effects of simplifying the process, controlling the coarsening of the structure and shortening the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

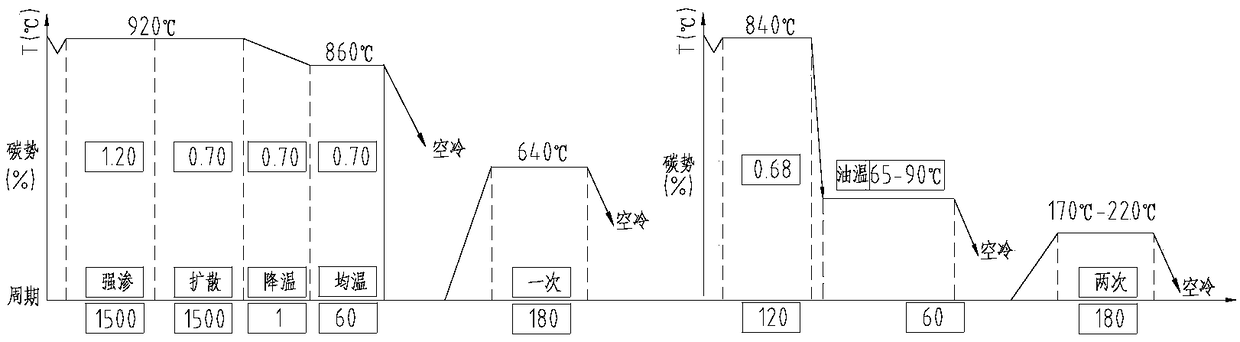

[0086] The selected gear material of this embodiment is low carbon alloy steel 18CrNiMo7-6, its A c1 Point is 738°C, A c3 The temperature is 815°C, and the effective hardened layer depth is required to be 3.0-3.4mm. Conventional carburizing gears are put into the furnace at 900°C, and the carburizing process temperature is 920°C. It takes 50 hours for the process of strong infiltration and diffusion at this temperature. After tempering at 640°C, reheat to 840°C for quenching, such as figure 1 shown. Table 1 shows the structure and properties after conventional carburizing treatment, and Table 2 shows the mechanical properties after this process. Figure 2a is the surface tissue under this process, Figure 2b It is the heart tissue under this process. The conventional carburizing process takes a very long time, and after a long time of heat preservation, the structure grows and the mechanical properties decrease.

[0087] Table 1

[0088]

[0089] Table 2

[0090] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com