Rotating type drying frame in process of textile fabric printing and dyeing technology

A printing and dyeing process, a technology for textile fabrics, applied in the processing of textile materials, processing textile material carriers, textiles and papermaking, etc., can solve the problems of wasting electric energy, not suitable for fabrics, etc., and achieve the effect of good flexibility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

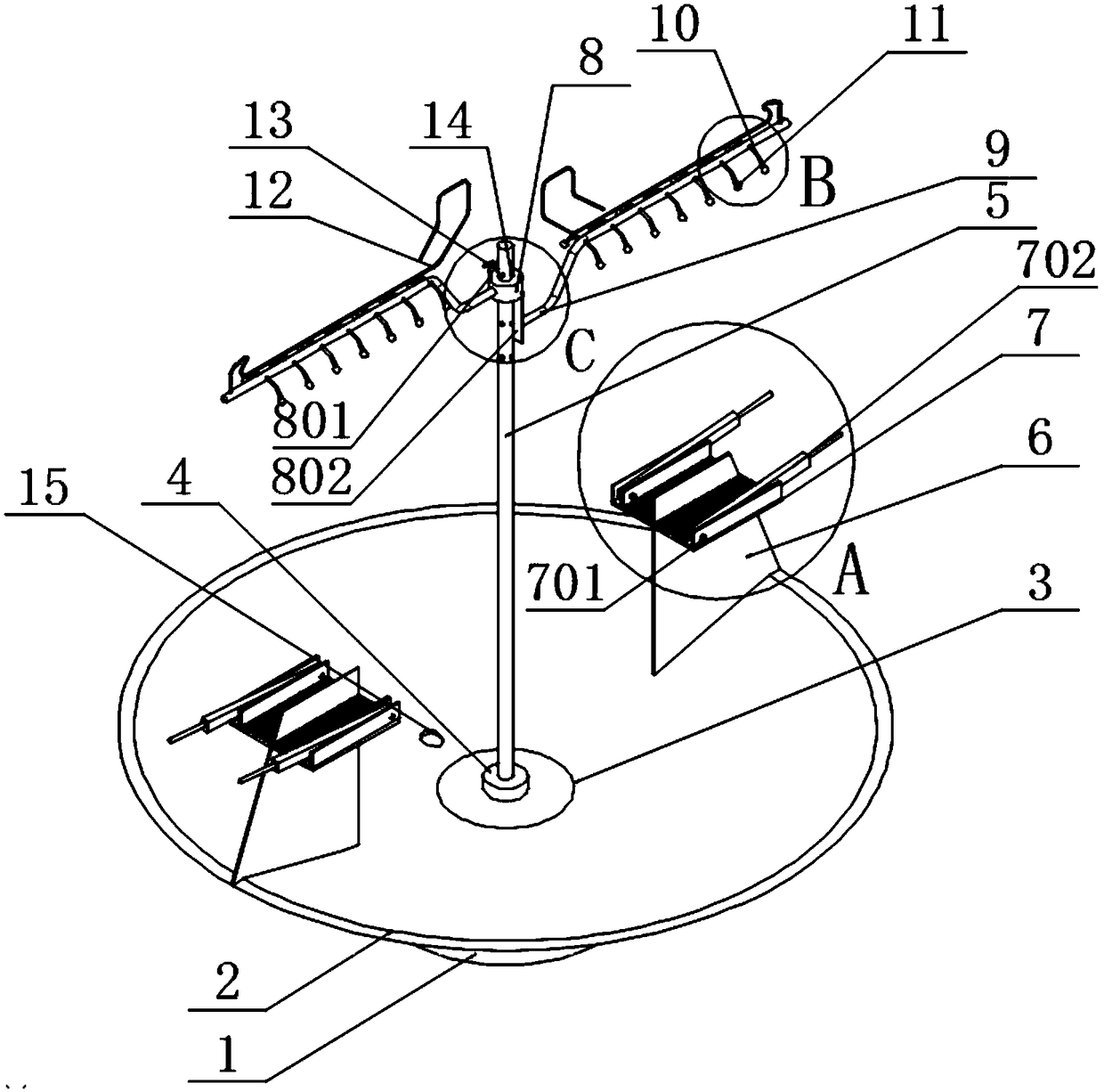

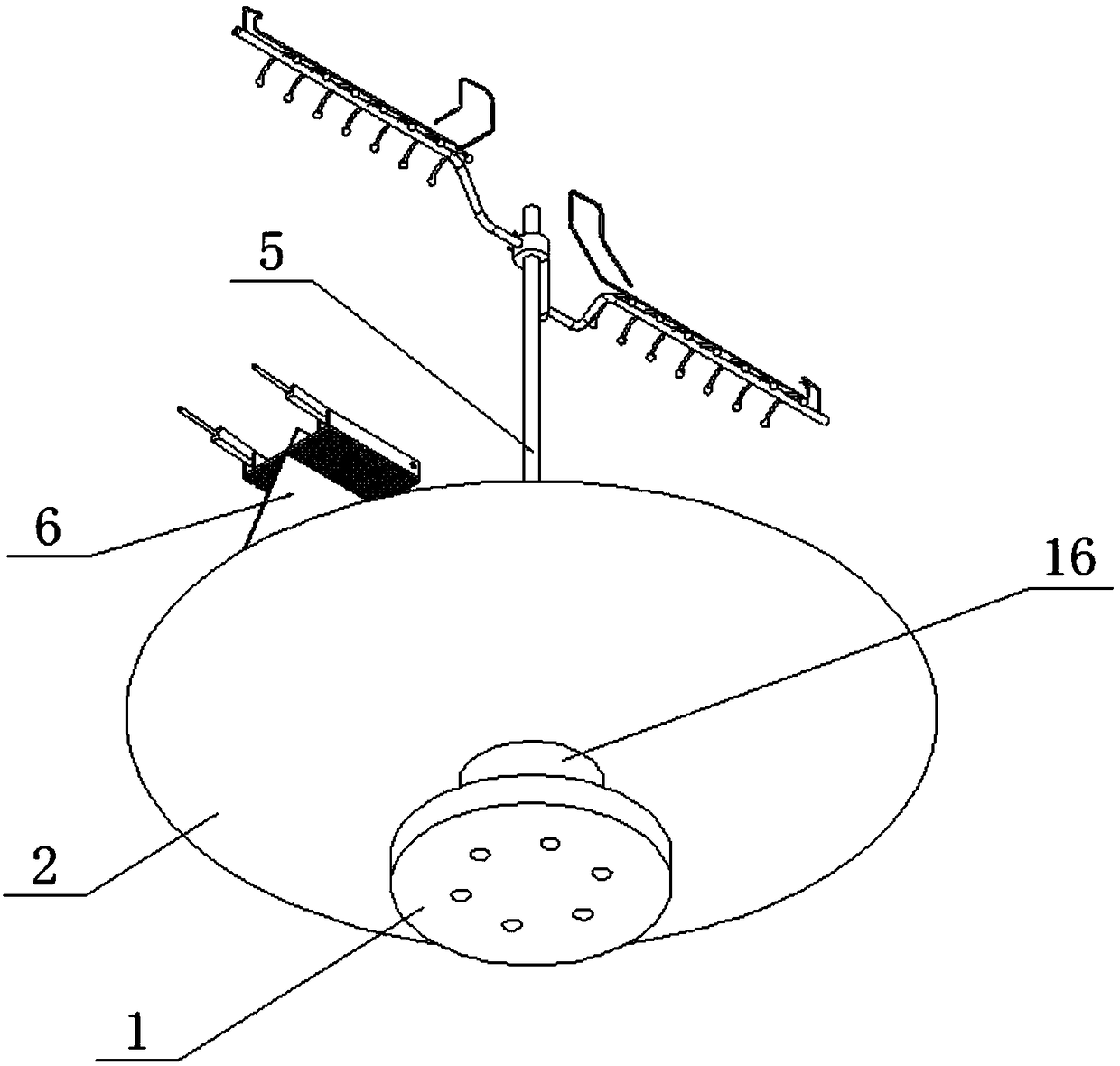

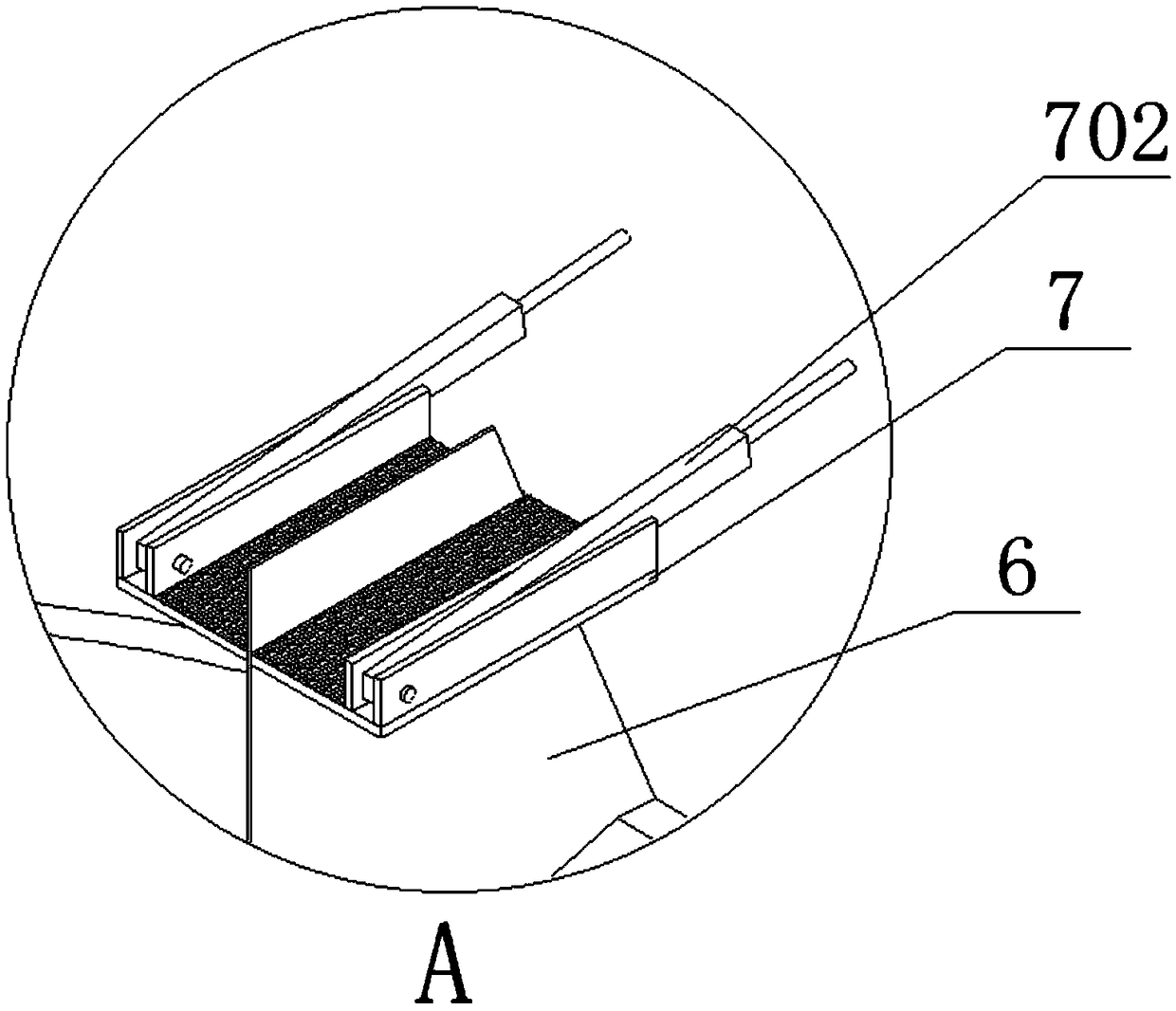

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides a rotary drying rack in the process of printing and dyeing textile fabrics, comprising: a mounting base 1, a functional bucket 2, a rotating base 3, a bearing seat 4, a support rod 5, a functional base 6, a functional plate 7, and a rotating shaft 701 , pressing lever 702, adjusting seat 8, peg plate structure 801, lower turning plate structure 802, drying rack 9, strut 10, steel ball head 11, drying rod 12, positioning pin 13, positioning hole 14, dripping Holes 15, connecting columns 16 and connecting seats 17; the mounting base 1 is provided with a circle of inner sunken mounting holes for fixing the device on the ground, and a cone is installed vertically in the middle of the top surface of the mounting base 1 The connecting seat 17 of the platform structure, and a connecting column 16 is installed vertically on the top surface of the connecting seat 17; Through the bearing seat 4, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com