Multilevel pulp pulverizer for papermaking

A pulverizer, multi-level technology, applied in the field of papermaking equipment, can solve problems such as low efficiency, achieve uniform particle size, prevent adsorption and accumulation, and achieve high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

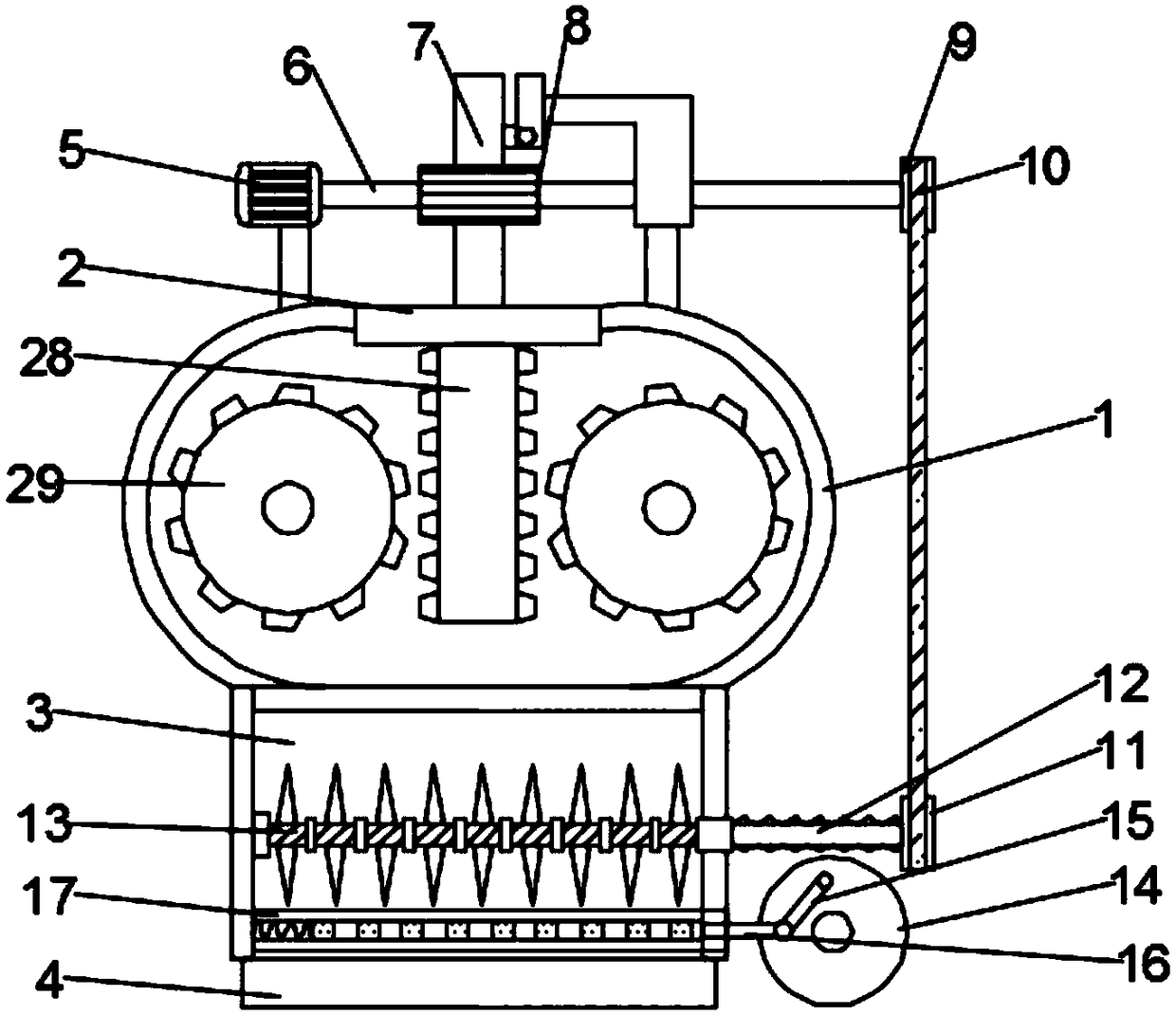

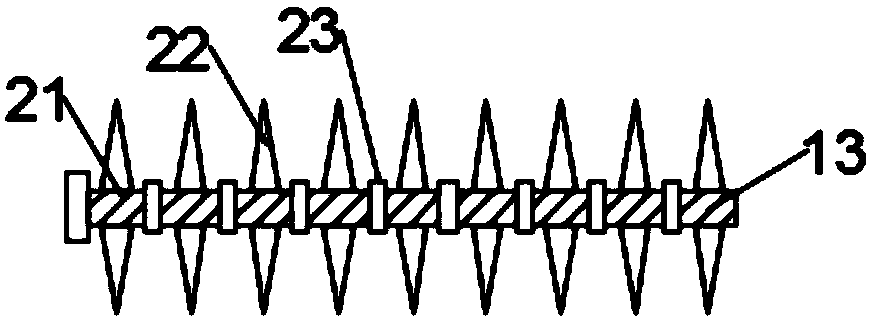

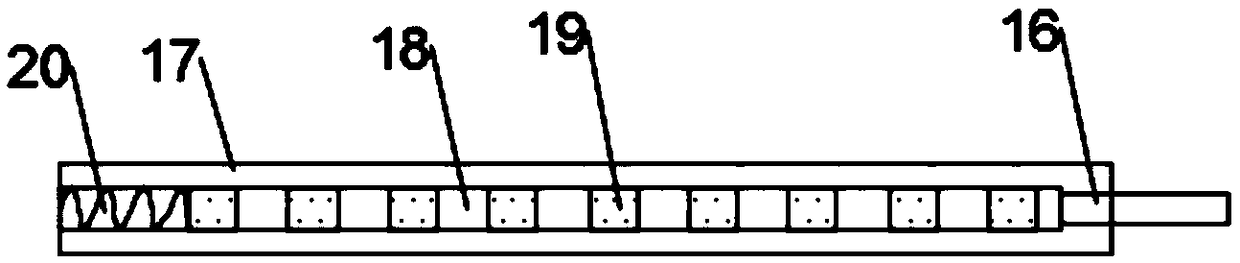

[0020] see Figure 1~3 , in an embodiment of the present invention, a multi-layer pulp pulverizer for papermaking, including a machine body 1, a material inlet 2, a pulverization chamber 3, a discharge port 4 and a working motor 5, and a pulverization chamber 3 is arranged inside the body 1 , the upper middle position of the body 1 is provided with a material inlet 2, the material inlet 2 communicates with the crushing chamber 3, a discharge port 4 is provided below the body 1, and a discharge chamber is provided above the discharge port 4 17. The upper part of the discharge chamber 17 communicates with the crushing chamber 3, the upper left of the body 1 is provided with a working motor 5, and a sieve plate 18 is movable inside the discharge chamber 17;

[0021] The working motor 5 is a forward and reverse motor, and the model of the working motor 5 is X6215-KV350; the working motor 5 is fixedly welded on the upper part of the body 1, and the output shaft on the right side of...

Embodiment 2

[0025] like Figure 4 As shown, in this embodiment, the worm 12 is replaced by a third rotating shaft 24, the left end of the third rotating shaft 24 is fixedly welded to the lower crushing assembly 13, and the right side of the third rotating shaft 24 is fixedly installed with a winding wheel 25. A stay rope 26 is wound on the reel 25, and a fixed pulley 27 is arranged parallel to the bottom of the reel 25. The end of the stay cord 26 away from the reel 25 bypasses the fixed pulley 27 and runs through The inner cavity of the second hinged rod 16 is connected to the middle position of the right side wall of the sieve plate 18. Other structures in this embodiment are the same as those in Embodiment 1. The release of pulp can effectively avoid the accumulation of pulp in the crushing chamber 3 .

[0026] The working principle of the present invention is: the pulp enters the crushing chamber 3 through the feeding port 2, and the working motor 5 starts to drive the first rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com