General connector for prefabricated building steel structure frame

A technology of structural frame and construction steel, which is applied in the direction of building components, building structure, construction, etc., can solve the problems of impossibility, trouble, and poor effect, and achieve the effect of strong practicability, convenient use, and good general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

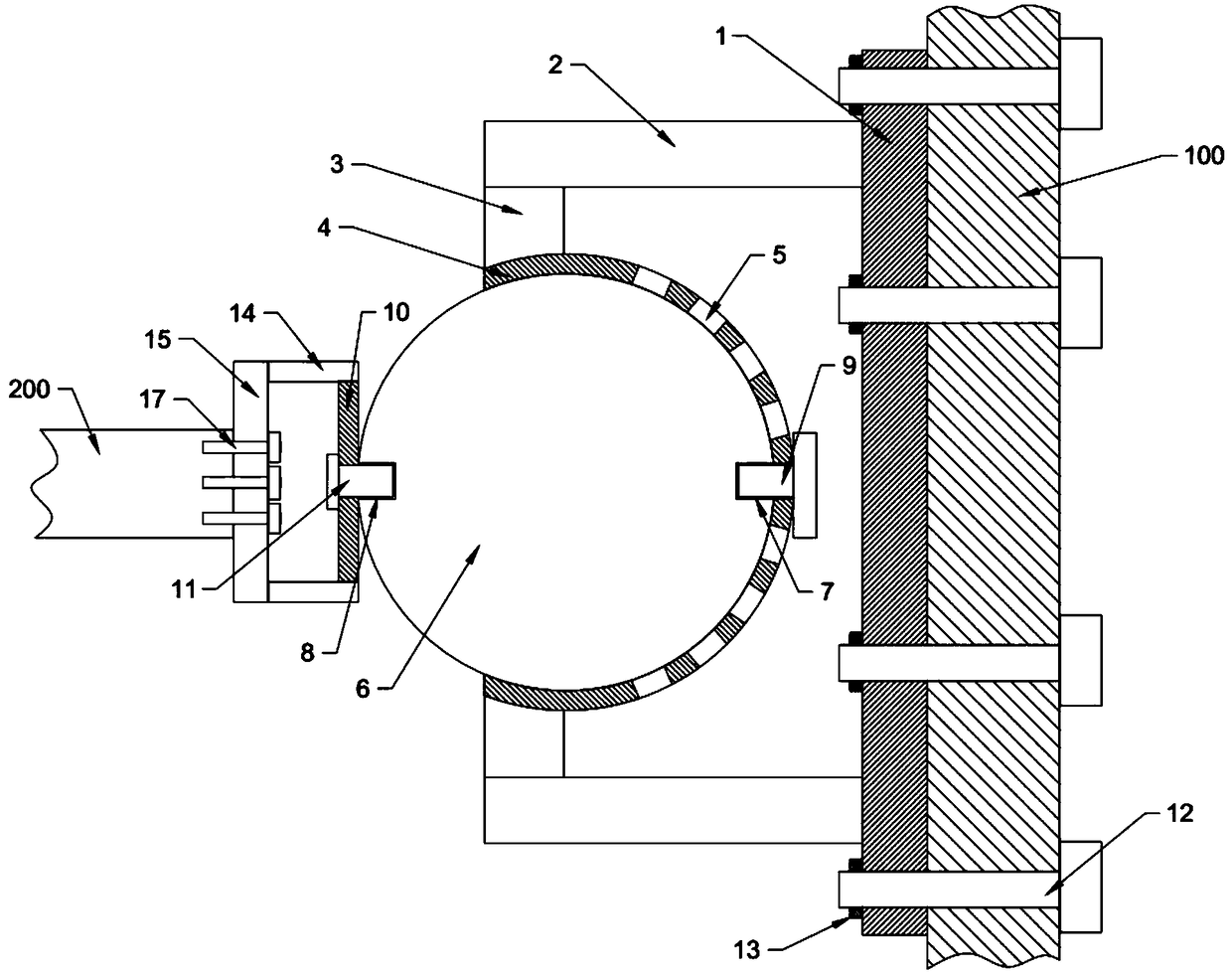

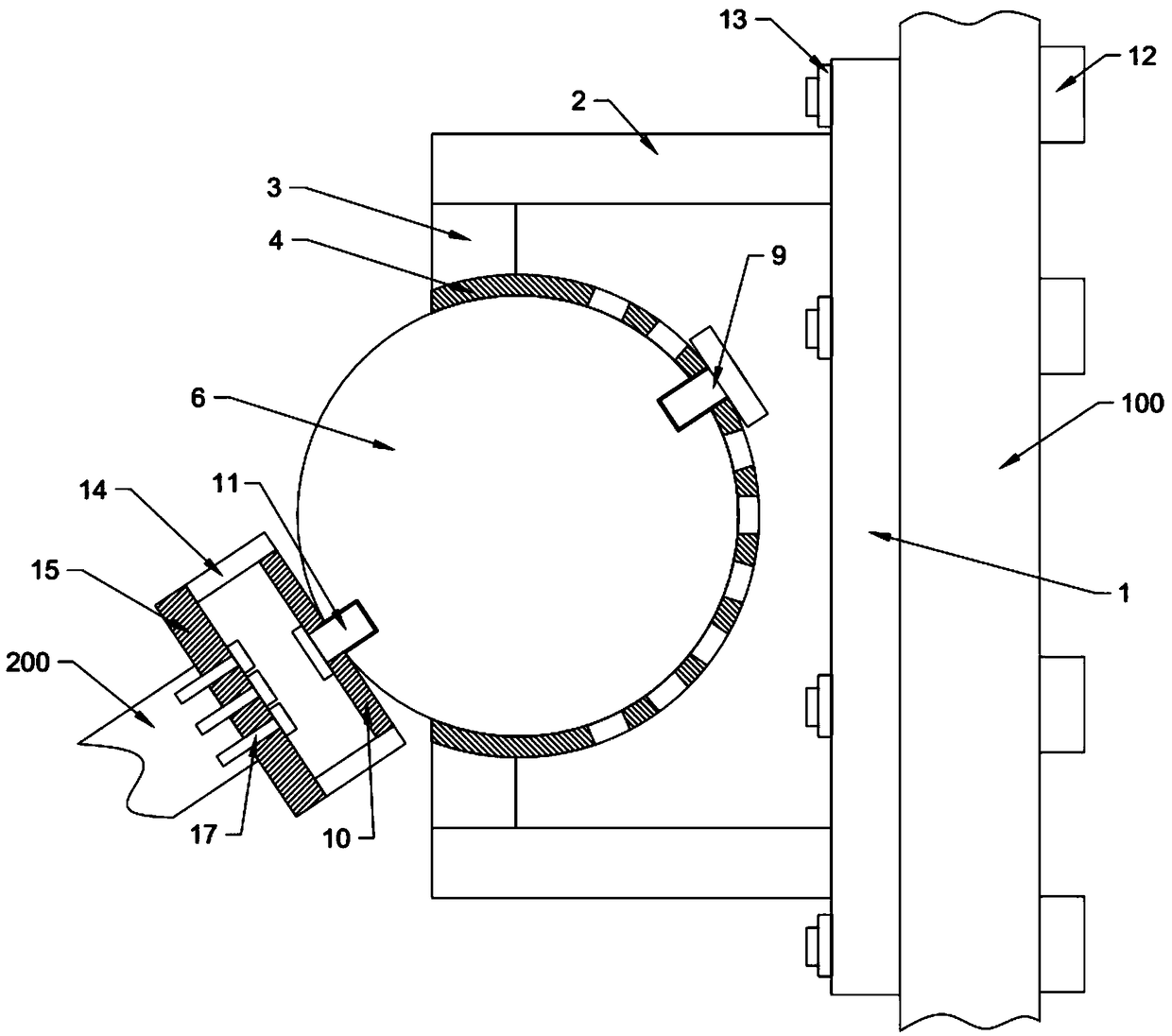

[0034] A kind of general connector of prefabricated building steel structure frame, including fixing mechanism and connecting mechanism, as attached to the instruction manual figure 1 As shown, the fixing mechanism is fixedly connected to the wallboard 100, and the connecting mechanism is fixedly connected to the steel beam 200. Through the fixing mechanism and the connecting mechanism of the universal connector, the wallboard 100 and the steel beam 200 can be connected to realize assembly, which is better It is used to install and fix the frame of the building steel structure.

[0035] The fixing mechanism includes a board 1, a cover board 3 and a spherical cover 4, the board 1 is fixedly connected with the wall board 100, the board 1 and the wall board 100 are connected by the board screw 12, and the tail end of the board screw 12 is fixed Bolts 13 are connected, and the veneer 1 is fixed to the wallboard 100 by the veneer screws 12, and the bolts 13 are locked to make the c...

Embodiment 2

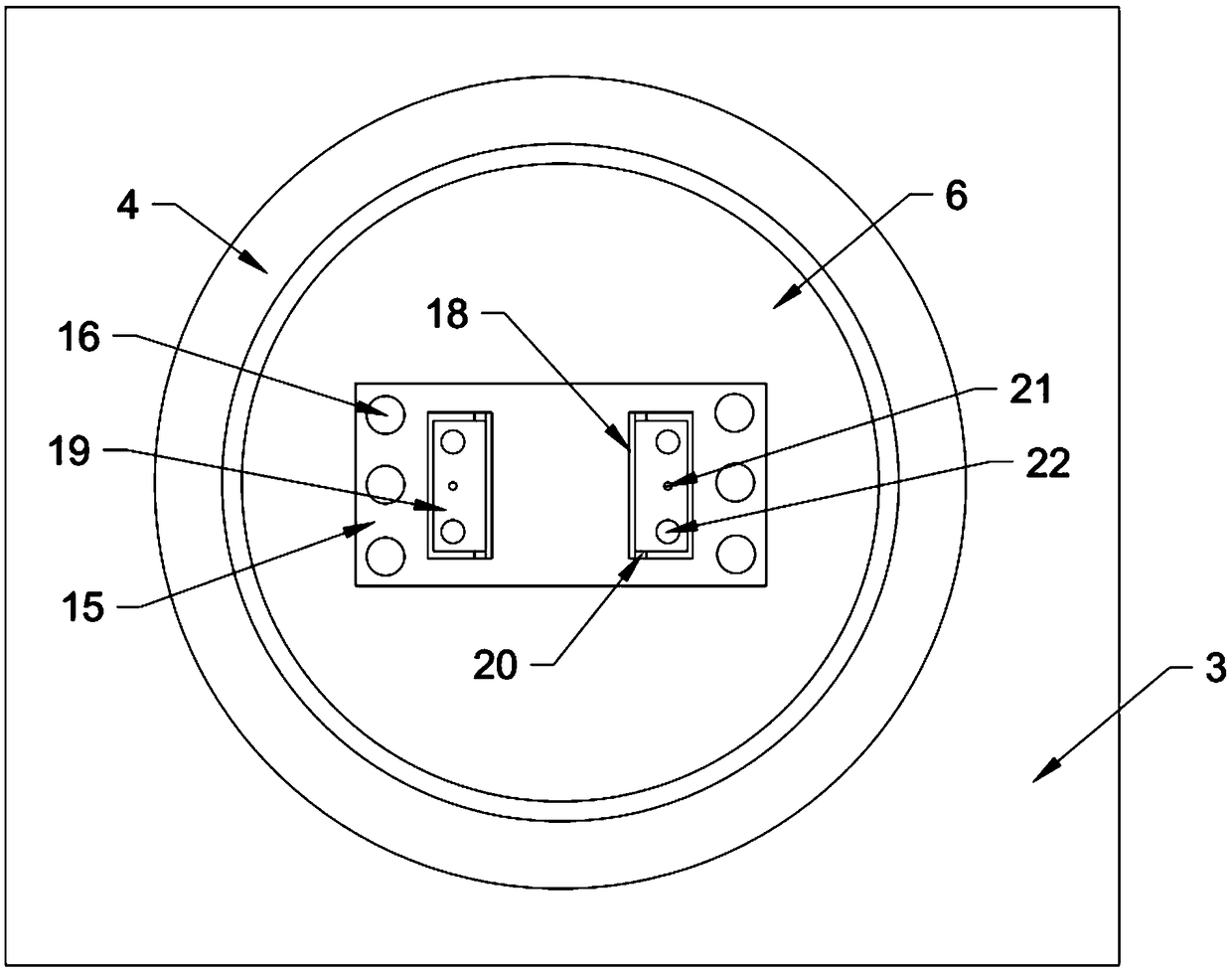

[0039] The difference from Embodiment 1 is: the attached image 3As shown, in order to realize the horizontal installation of the steel beam 200, the middle part of the connecting plate 15 is symmetrically provided with an overturning groove 18, and a rotating plate 19 is movably arranged in the overturning groove 18, and a rotating shaft 20 is rotated and inserted on the rotating plate 19, and the two ends of the rotating shaft 20 All are fixedly connected on the side wall of the turning groove 18;

[0040] The rotating plate 19 is provided with connecting holes 21, and the two sides of the connecting holes 21 are provided with transverse installation holes 22. The transverse installation holes 22 and the steel beam 200 are fixedly connected by transverse screws 23, and the two connecting holes 21 are connected by a fixed plate rod 24. Connect, and both ends of the fixed plate rod 24 are fixedly connected with nuts 25. When the steel beam 200 needs to be installed horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com