anti-skid device

A technology of anti-skid device and gear, applied in the direction of building, building reinforcements, building components, etc., can solve the problems of inability to grip steel strands and weak tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

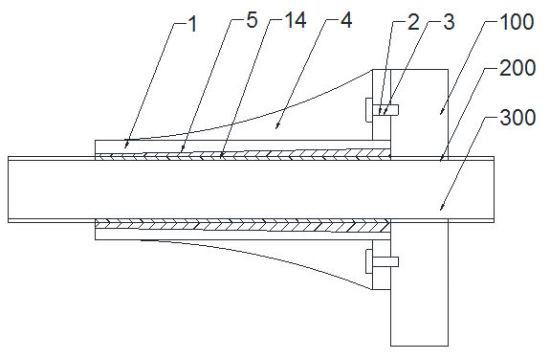

[0029] Such as figure 1 , figure 2 As shown, a kind of anti-slip device provided by the present invention is used to cover on the steel strand 300 with epoxy resin outer layer 200 near one end of the fixed column 100; comprising: force component sleeve 1; the proximity of the force component sleeve One end of the fixed column has a contact base 2; the contact base is fixed on the fixed column by a fastener 3. There are a plurality of reinforcing ribs 4 on one side of the contact base, and the width of the reinforcing ribs converges from one end adjacent to the fixing column to the other end.

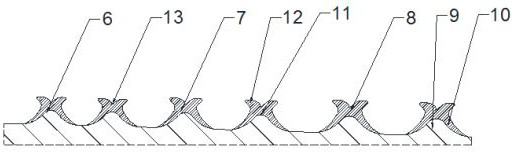

[0030] The inner diameter of the force component sleeve converges from one end close to the fixed column to the other end away from the fixed column, forming an inclined inner tapered surface 5 . The inner wall of the force component sleeve is provided with multiple sets of ring gears; the ring gears include a first gear 6, a second gear 7 and a third gear 8, the first gear, the secon...

Embodiment 2

[0035] An anti-skid device provided by the present invention is used to cover a steel strand with an outer layer of epoxy resin near one end of a fixed column; comprising: a force component sleeve; the inner wall of the force component sleeve is provided with multiple groups of ring gears ; The ring gear has inner hard teeth and outer soft teeth covering the outer surface of the inner hard teeth, the hardness of the inner hard teeth is less than the hardness of the steel strand, and the hardness of the outer soft teeth is less than the inner hard teeth hardness; on the axial section, the inner hard tooth is a convex peak with a rounded curve, and the outer side of the outer soft tooth has a pair of protruding heads bifurcated to both ends; when installed, the protruding After the head squeezes into the epoxy resin layer of the steel strand, it touches the steel strand and bends and deforms to form an anti-skid layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com