Preparation method of color filter film based on microfluidic and quantum dot technology

A color filter film, quantum dot technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of color purity decline, achieve good white balance, achieve white balance, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing a color filter film based on microfluidics and quantum dot technology, comprising the following steps,

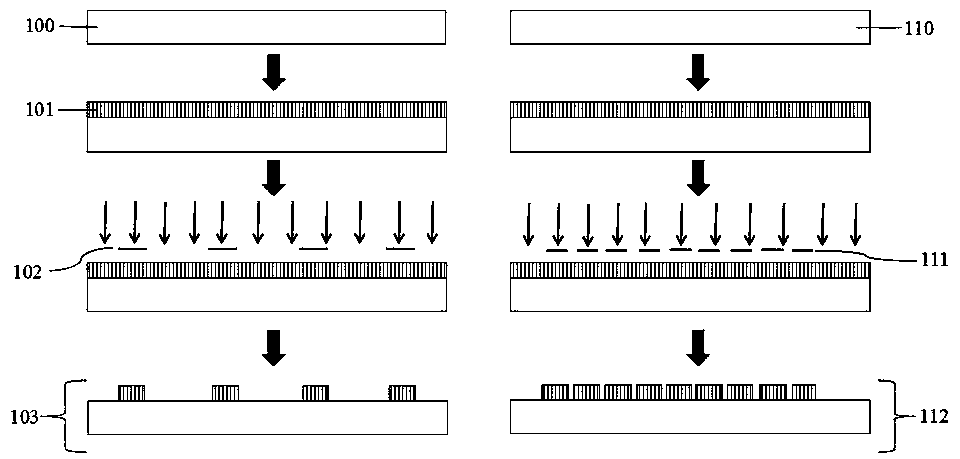

[0050] S01: Design a first template and a second template with patterns according to the pixel structure of the display screen;

[0051] S02: Prepare a first PDMS template and a second PDMS template with microchannels by photolithography and soft printing, and punch holes in the first PDMS template and the second PDMS template to prepare liquid inlet holes and liquid outlet holes;

[0052] S03: Prepare quantum dot inks with different luminous wavelengths;

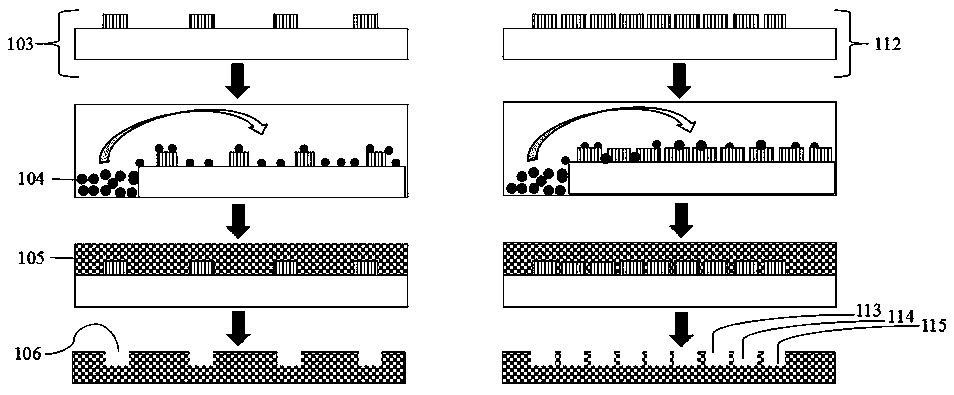

[0053] S04: Press the first PDMS template and the transparent substrate (the transparent substrate is glass or quartz), and use the microfluidic method to inject the first quantum dot ink into the first PDMS template through the liquid inlet hole and connect with the liquid inlet hole microchannel, and curing;

[0054] S05: Separate the first PDMS template from the t...

Embodiment 1

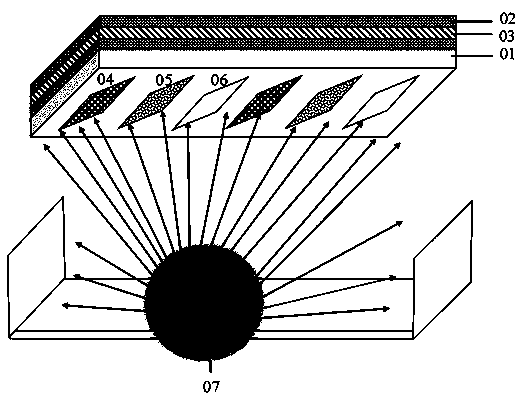

[0072] Such as figure 1 As shown, a method for preparing a color filter film based on microfluidics and quantum dot technology is characterized in that it comprises the following steps:

[0073] S01: Design a patterned graphic first template 103 and a graphic second template 112 according to the pixel structure of the display screen;

[0074] S02: Prepare PDMS templates by photolithography and soft printing methods, and punch holes on the templates to prepare liquid inlet holes and liquid outlet holes;

[0075] S03: Prepare red and green quantum dot inks;

[0076] S04: Pressing the first PDMS template and the transparent substrate 01, using a syringe pump to press the first quantum dot ink 04 into the PDMS channel, and curing;

[0077] S05: Separate the PDMS template from the transparent substrate 01, align and press the second PDMS template with the transparent substrate provided with the first type of quantum dots, and use a syringe pump to press the second type of quantum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com