Chili processing process

A processing technology and pepper technology, which is applied in the field of agricultural product production and processing, can solve the problem of chili powder with strong spicy taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

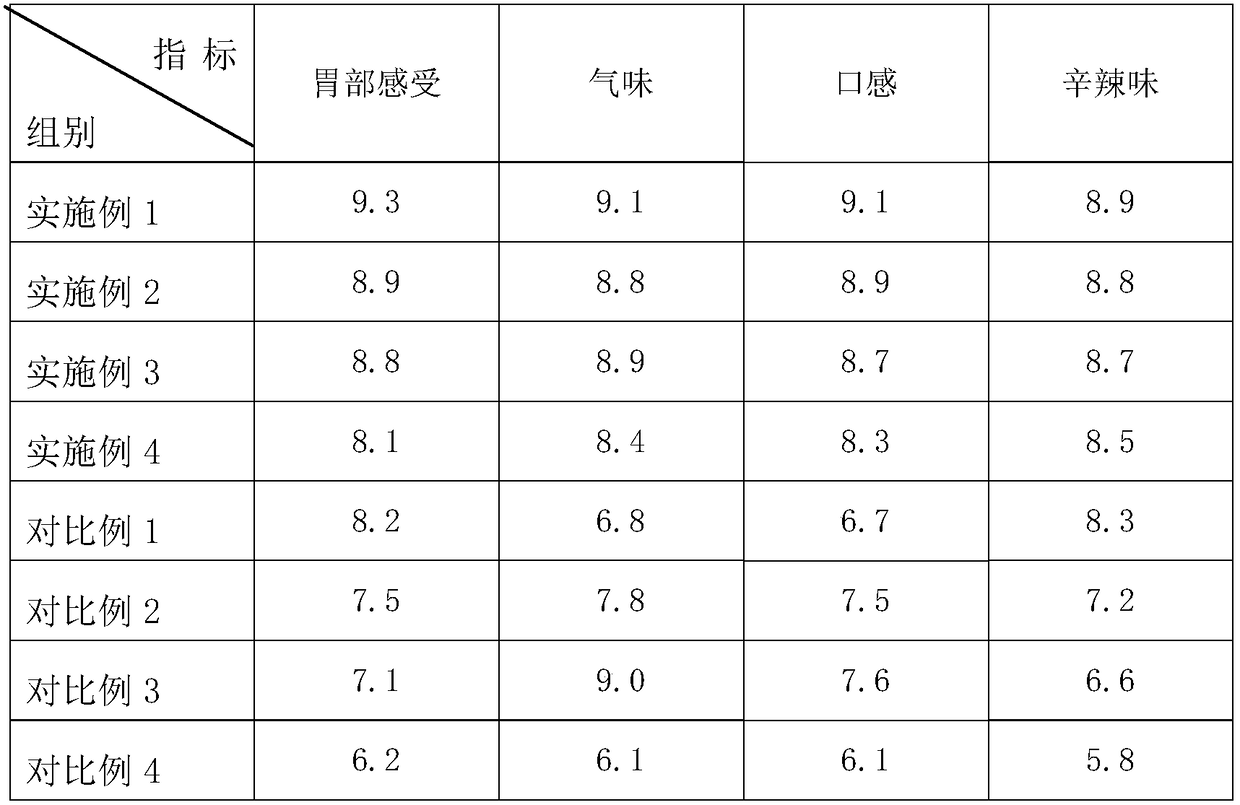

Examples

Embodiment 1

[0022] A processing technology of pepper, which is characterized in that it comprises the following steps:

[0023] Step 1. Put 9 parts of camphor branches and 8 parts of mint leaves into 90 parts of water and boil for 2 hours according to weight parts, then filter to obtain filtrate, boil at 90℃; add weight parts to the filtrate Obtain soaking liquid for 18 parts of liquor;

[0024] Step 2: Cut the skin of the fresh chili until it is connected to the internal cavity, and then put it in the soaking liquid and soak it for 2 days at a temperature of 20°C; during the soaking process, the soaking liquid completely submerge the chili;

[0025] Step 3: Dry the soaked pepper to a moisture content of 35% and a drying temperature of 70°C;

[0026] Step 4. Put the dried peppers in step 3 into processed ash for 25 minutes, and keep the temperature of the processed ash at 90°C during processing; the processed ash is obtained by burning cypress branches and leaves; ensure the surface of the pepper...

Embodiment 2

[0029] A processing technology of pepper, which is characterized in that it comprises the following steps:

[0030] Step 1. Put 12 parts of camphor branches and 5 parts of mint leaves into 80 parts of water and boil for 2 hours according to weight parts, then filter to obtain filtrate, boil at 80°C; add weight parts to the filtrate Obtain soaking liquid for 15 parts of liquor;

[0031] Step 2: Cut the skin of the fresh chili until it is connected to the internal cavity, and then put it in the soaking liquid and soak it for 3 days at a temperature of 15°C; during the soaking process, the soaking liquid completely submerge the chili;

[0032] Step 3: Dry the soaked pepper to a moisture content of 40% and a drying temperature of 60°C;

[0033] Step 4. Put the dried chili peppers in step 3 into processed ash for 30 minutes, and maintain the temperature of the processed ash at 95°C during processing; the processed ash is obtained by burning cypress branches and leaves; ensure the surface o...

Embodiment 3

[0036] A processing technology of pepper, which is characterized in that it comprises the following steps:

[0037] Step 1. Put 8 parts of camphor branches and 6 parts of mint leaves into 100 parts of water and boil for 1 hour according to parts by weight, and then filter to obtain filtrate. The boiling temperature is 100°C; add parts by weight to the filtrate Obtain soaking liquid for 20 parts of liquor;

[0038] Step 2. Cut the skin of the fresh chili until it is connected to the internal cavity, and then put it in the soaking liquid and soak it for 2 days at a temperature of 30°C; during the soaking process, the soaking liquid completely submerge the chili;

[0039] Step 3: Dry the soaked chili until the water content is 30% and the drying temperature is 80°C;

[0040] Step 4. Put the dried peppers in step 3 into processed ash and process for 20 minutes. During processing, keep the temperature of the processed ash at 100°C; the processed ash is obtained by burning cypress branches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com