Grinding and stirring device for mutton sheep breeding feed

A stirring device and feed technology, applied in the field of breeding, can solve the problems of poor crushing and refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

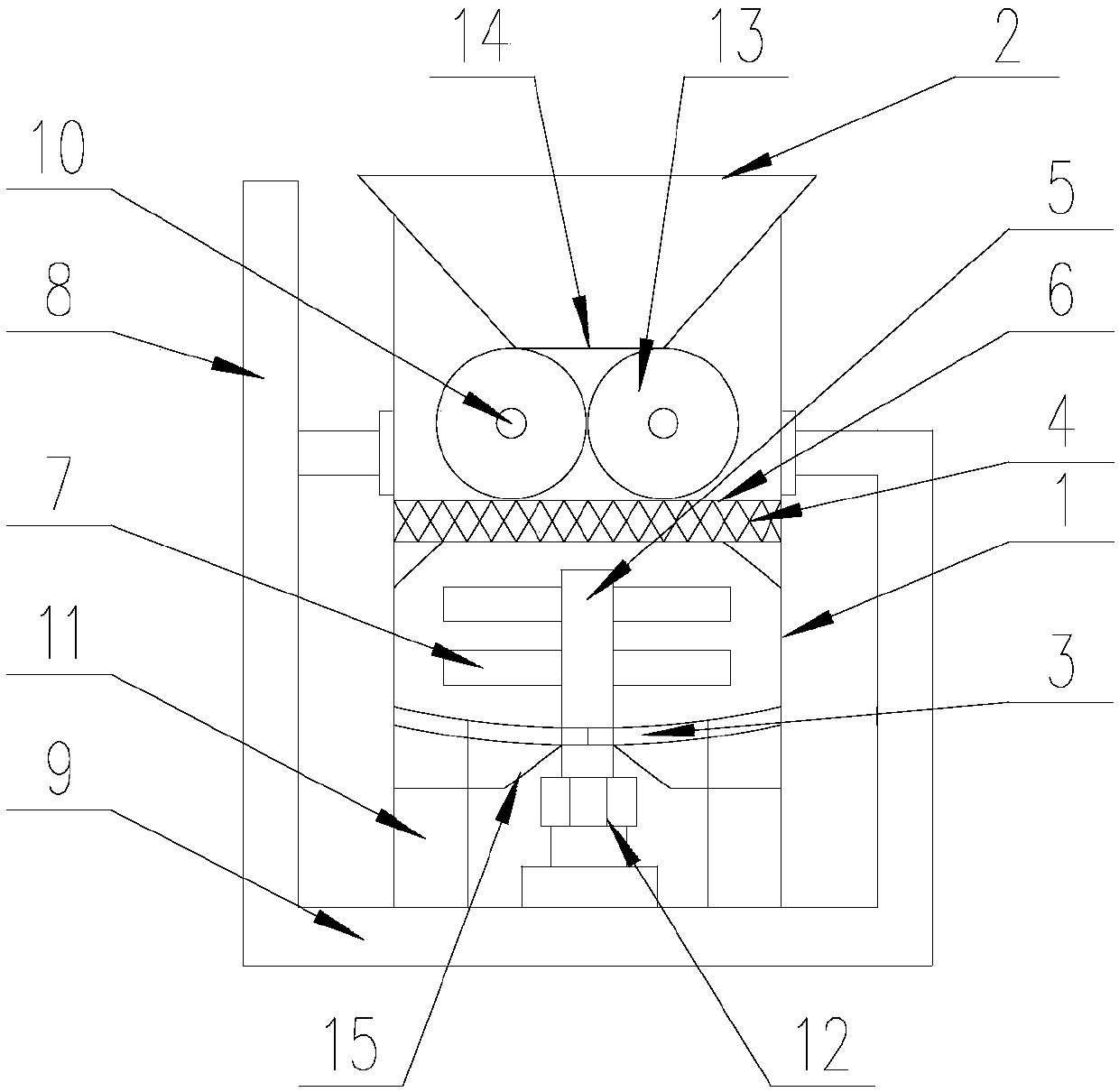

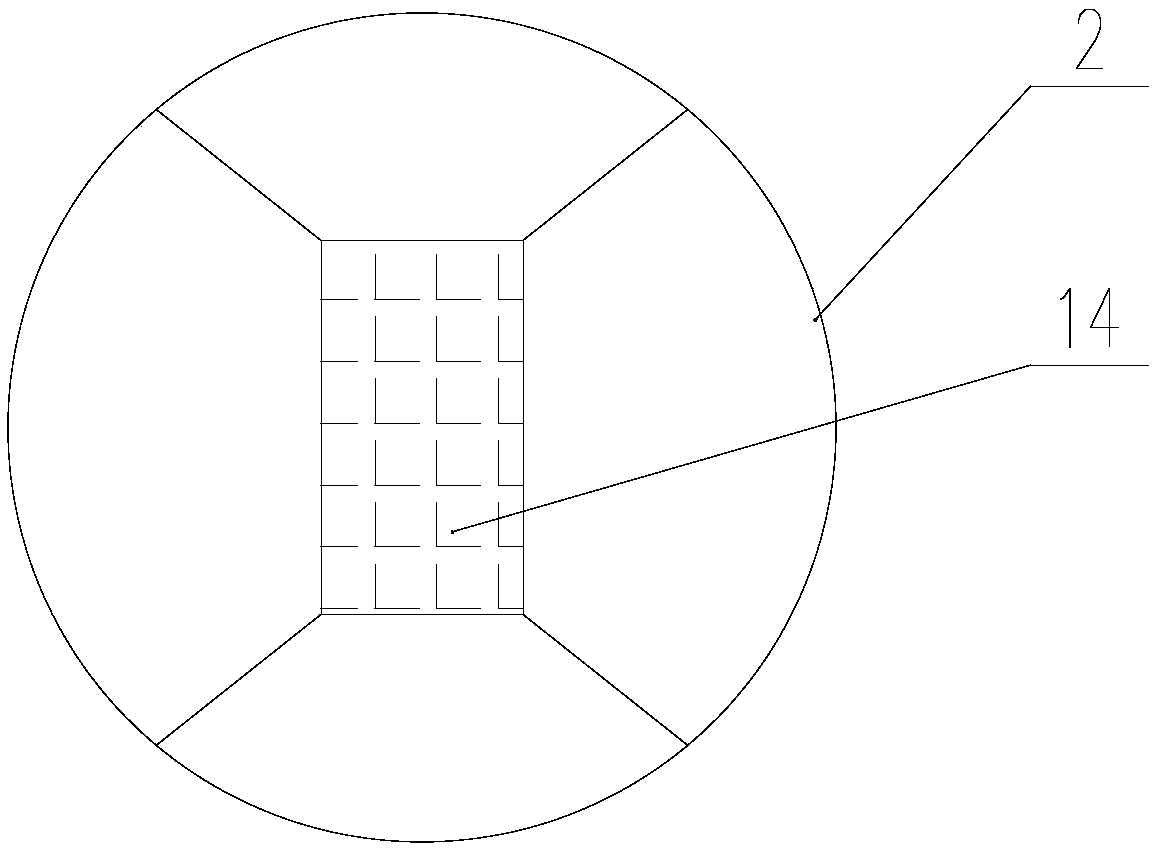

[0030] like figure 1 and figure 2 As shown, a grinding and stirring device for mutton sheep breeding feed includes a body 1, a feeding bin 2 positioned at the top of the body 1, a roll device positioned at the middle of the body 1, and a stirring device positioned at the lower end of the body 1. The bottom of the body 1 is provided with a The feed port, the roll device includes a screen plate 4 horizontally arranged on the side wall of the body 1, and the screen plate 4 divides the body 1 into a roll area and a stirring area, and the side wall of the roll area Two supports are arranged oppositely, and the rotating shaft 10 parallel to the filter screen plate 4 is arranged on the support, and the rolling drum 13 is coaxially installed on the rotating shaft 10 and can rotate together with the rotating shaft 10, and the rotating shaft 10 is connected to the rotating motor , the two rolling cylinders 13 are in contact with each other, and the two rolling cylinders 13 are in cont...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that a grinding and stirring device for mutton sheep breeding feed also includes a fixed frame, and the fixed frame includes two vertical columns 8 parallel to each other and a horizontal horizontal column vertically connected to the bottom of the vertical column 8 A support platform 9, a horizontal fixed column is also provided on the vertical column 8 to detachably connect with the body 1, the body 1 is placed on the horizontal support platform 9, and the fixed frame can support the body 1 And fixation to prevent its vibration and displacement during use.

[0044] The vertical column 8 of the left part adopts a hydraulic cylinder to realize expansion and contraction.

[0045] A connection plate is arranged on the horizontal fixed column, and a plurality of through holes are arranged on the connected plate, and a plurality of bolts are arranged at the connecting part of the body 11 connected with the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com