Intelligent production drilling device with automatic cleaning function

An intelligent production and automatic cleaning technology, which is applied in the direction of manufacturing tools, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of automatic and efficient cleaning of waste, and achieve the effects of reducing labor intensity, saving time and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

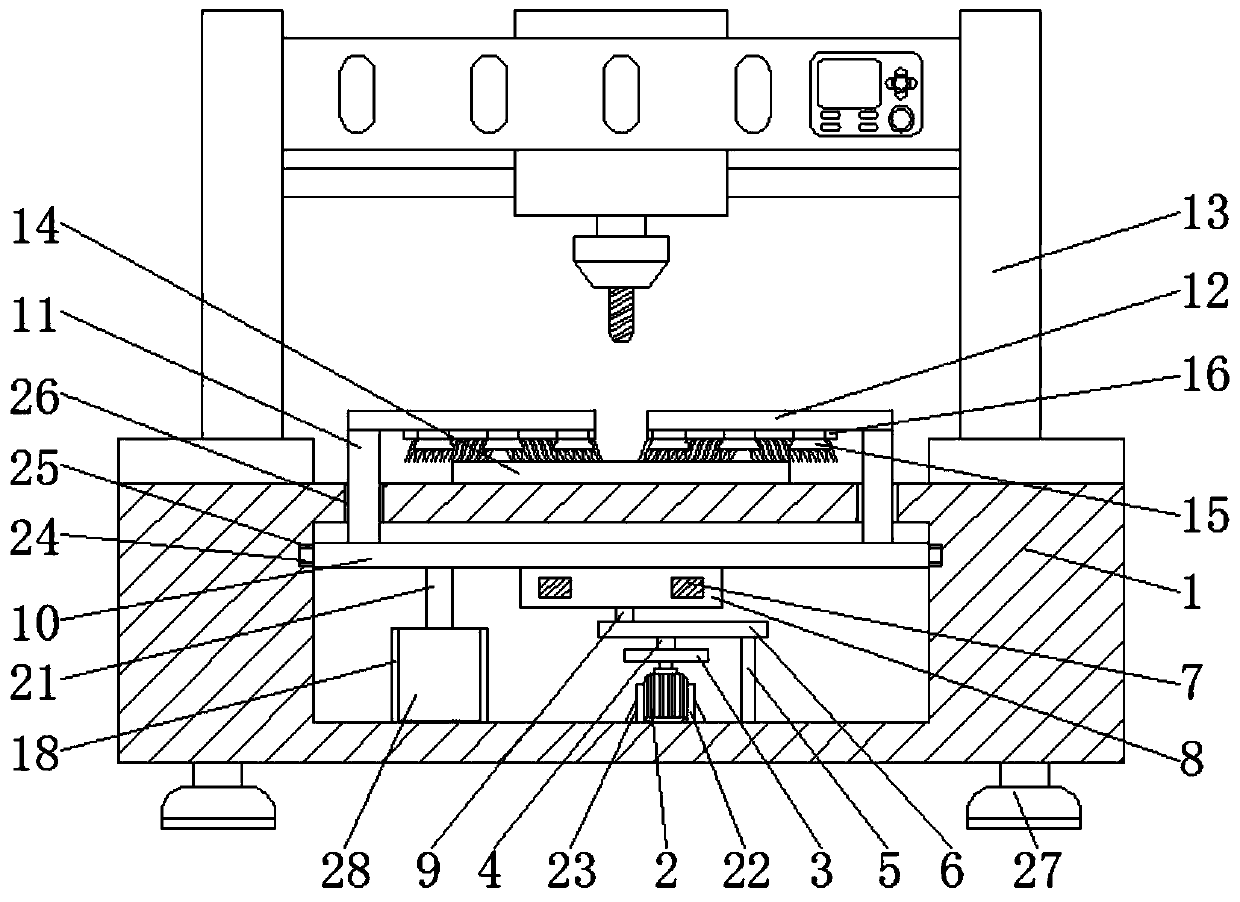

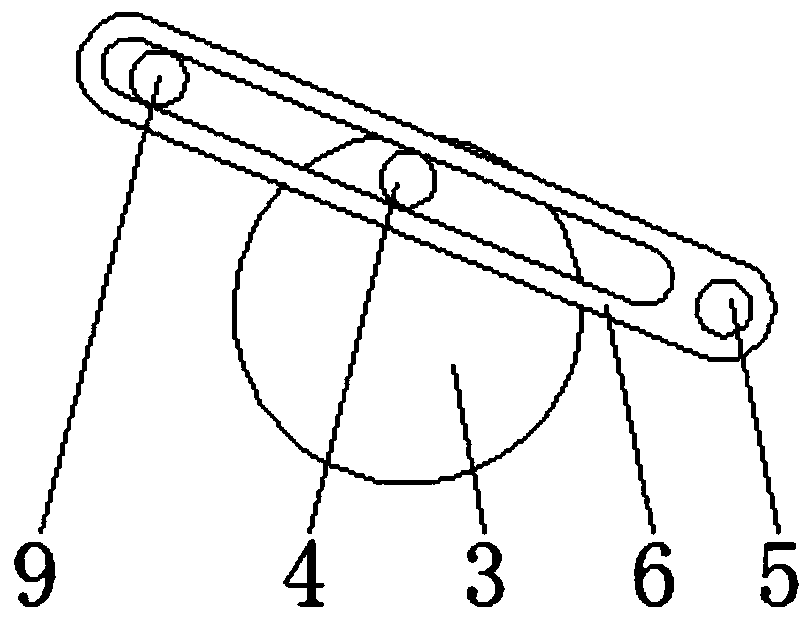

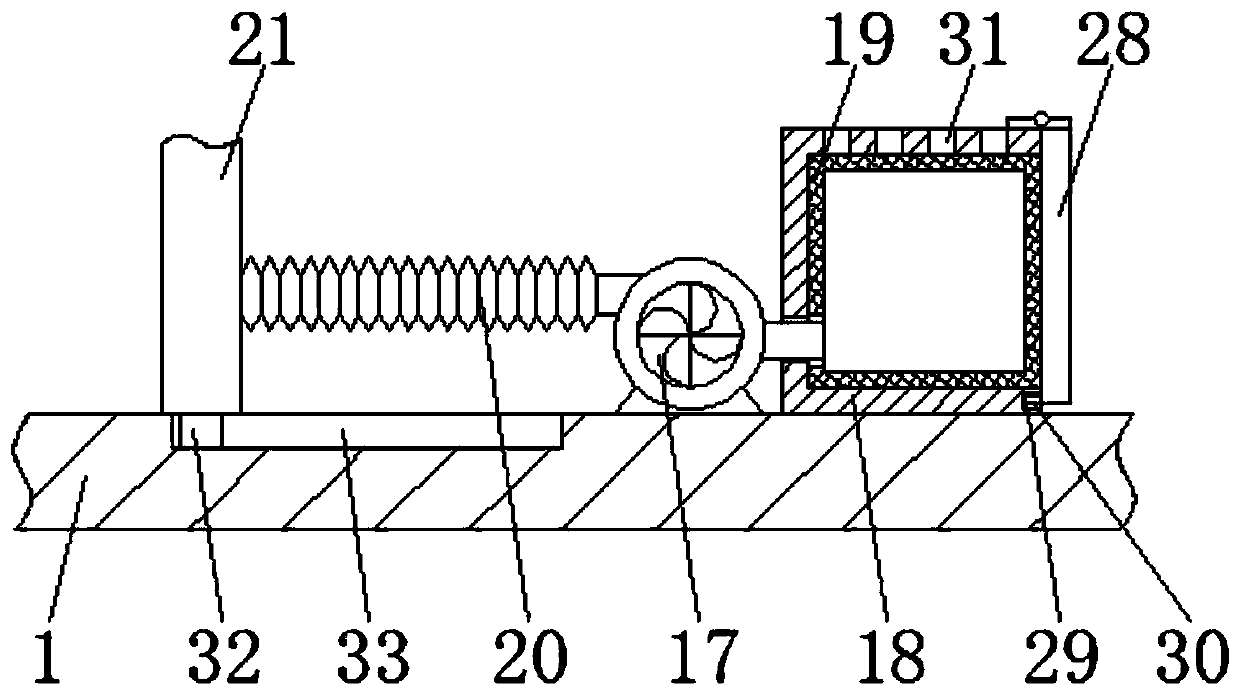

[0031] The intelligent production drilling device with automatic cleaning function of the present invention comprises a bottom box 1, a motor 2 is fixedly connected to the right side of the bottom of the inner wall of the bottom box 1, and a disc 3 is fixedly connected to the output end of the motor 2. The top is fixedly connected with a first movable rod 4, and the right side of the inner wall bottom of the bottom box 1 is fixedly connected with a vertical rod 5, the vertical rod 5 is located on the right side of the motor 2, the surface of the vertical rod 5 is covered with a frame 6, and the inside of the frame 6 Slidingly connected with the surface of the first movable rod 4, both sides inside the bottom box 1 are provided with a slide bar 7, the front and back of the slide bar 7 are fixedly connected with the inner wall of the bottom box 1, and the surface of the slide bar 7 is sleeved with Sliding plate 8, the bottom of sliding plate 8 is fixedly connected with second mov...

Embodiment 2

[0033]The intelligent production drilling device with automatic cleaning function of the present invention comprises a bottom box 1, a motor 2 is fixedly connected to the right side of the bottom of the inner wall of the bottom box 1, and a disc 3 is fixedly connected to the output end of the motor 2. The top is fixedly connected with a first movable rod 4, and the right side of the inner wall bottom of the bottom box 1 is fixedly connected with a vertical rod 5, the vertical rod 5 is located on the right side of the motor 2, the surface of the vertical rod 5 is covered with a frame 6, and the inside of the frame 6 Slidingly connected with the surface of the first movable rod 4, both sides inside the bottom box 1 are provided with a slide bar 7, the front and back of the slide bar 7 are fixedly connected with the inner wall of the bottom box 1, and the surface of the slide bar 7 is sleeved with Sliding plate 8, the bottom of sliding plate 8 is fixedly connected with second mova...

Embodiment 3

[0036] The intelligent production drilling device with automatic cleaning function of the present invention comprises a bottom box 1, a motor 2 is fixedly connected to the right side of the bottom of the inner wall of the bottom box 1, and a disc 3 is fixedly connected to the output end of the motor 2. The top is fixedly connected with a first movable rod 4, and the right side of the inner wall bottom of the bottom box 1 is fixedly connected with a vertical rod 5, the vertical rod 5 is located on the right side of the motor 2, the surface of the vertical rod 5 is covered with a frame 6, and the inside of the frame 6 Slidingly connected with the surface of the first movable rod 4, both sides inside the bottom box 1 are provided with a slide bar 7, the front and back of the slide bar 7 are fixedly connected with the inner wall of the bottom box 1, and the surface of the slide bar 7 is sleeved with Sliding plate 8, the bottom of sliding plate 8 is fixedly connected with second mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com