Receiving device for organic glass bar extruder

A technology of plexiglass and material receiving device, which is applied in the field of plexiglass processing, can solve problems such as increasing labor costs, and achieve the effect of increasing labor costs and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

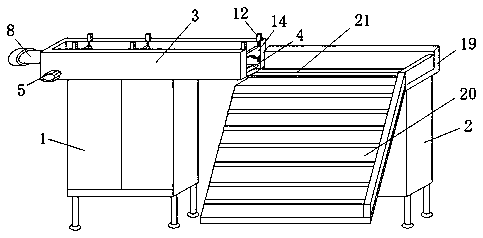

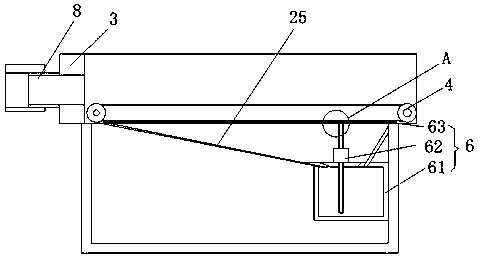

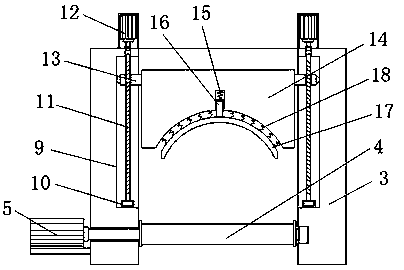

[0027] see Figure 1-6 , this embodiment provides a material receiving device for a plexiglass rod extruder, including a first frame 1 and a second frame 2, a material receiving box 3 is fixedly installed on the top of the first frame 1, and the material receiving box The inner wall of 3 is provided with a conveying device 4, a motor 5 is fixedly installed on the front of the receiving box 3, the output shaft of the motor 5 penetrates the receiving box 3 and is fixedly connected with the conveying device 4, and a water supply device is arranged inside the first frame 1 6. The top of the water supply device 6 is fixedly connected with evenly distributed nozzles 7. The high-pressure nozzles 7 are located below the conveying device 4. One side of the receiving box 3 is connected with a feeding pipe 8, and both sides of the inner wall of the receiving box 3 are opened. There is a moving groove 9, the bottom of the inner wall of the moving groove 9 is fixedly co...

Example Embodiment

[0029] Example 2

[0030] see Figure 1-6 , on the basis of Embodiment 1, a further improvement has been made: the bottoms of the first frame 1 and the second frame 2 are fixedly connected with supporting legs, and the bottoms of the supporting legs are fixedly connected with rubber blocks, and the shape of the rubber blocks is Isosceles trapezoid, the support legs play the role of supporting the whole device, and by setting the rubber block into an isosceles trapezoid, the contact area with the ground can be effectively increased, and the stability of the whole device is better. The conveying device 4 includes There is a conveyor belt body 41, the surface of the conveyor belt body 41 is provided with evenly distributed cleaning holes 42, the water supply device 6 includes a water supply tank 61, a water pump 62 is fixedly installed on the top of the water supply tank 61, and a water spray pipe 63 is connected to the top of the water pump 62, The spray head 7 is communicated ...

Example Embodiment

[0032] Example 3

[0033] see Figure 1-6 , on the basis of Example 1, a further improvement has been made: the cleaning brush 17 is a fan-shaped brush plate, and the inner side of the cleaning brush 17 is provided with raised cotton, and the cleaning brush 17 is set into a fan shape, which can make the contact area with the plexiglass rod. Larger, making cleaning more comprehensive, the raised cotton can wipe the surface of the plexiglass rod to make the surface more clean and tidy, the top of the placing seat 21 is provided with a fan-shaped groove to prevent the plexiglass rod from rolling down by itself, or the plexiglass rod The rods roll down to the side away from the inclined plate 20 , which prevents the plexiglass rods from accumulating on the receiving seat 19 .

[0034] Wherein, the inclination angle of the inclined plate 20 may be 60 degrees, and the top of the inclined plate 20 is fixedly connected with a deceleration strip. Both the inclined plate 20 and the dec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap