Pellet feed weighing device and using method thereof

A pellet feed and weighing device technology, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of scattered pellet feed, waste of time, labor intensity of workers, low production efficiency, etc., to avoid misoperation and processing efficiency , Improve the effect of a collection process and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

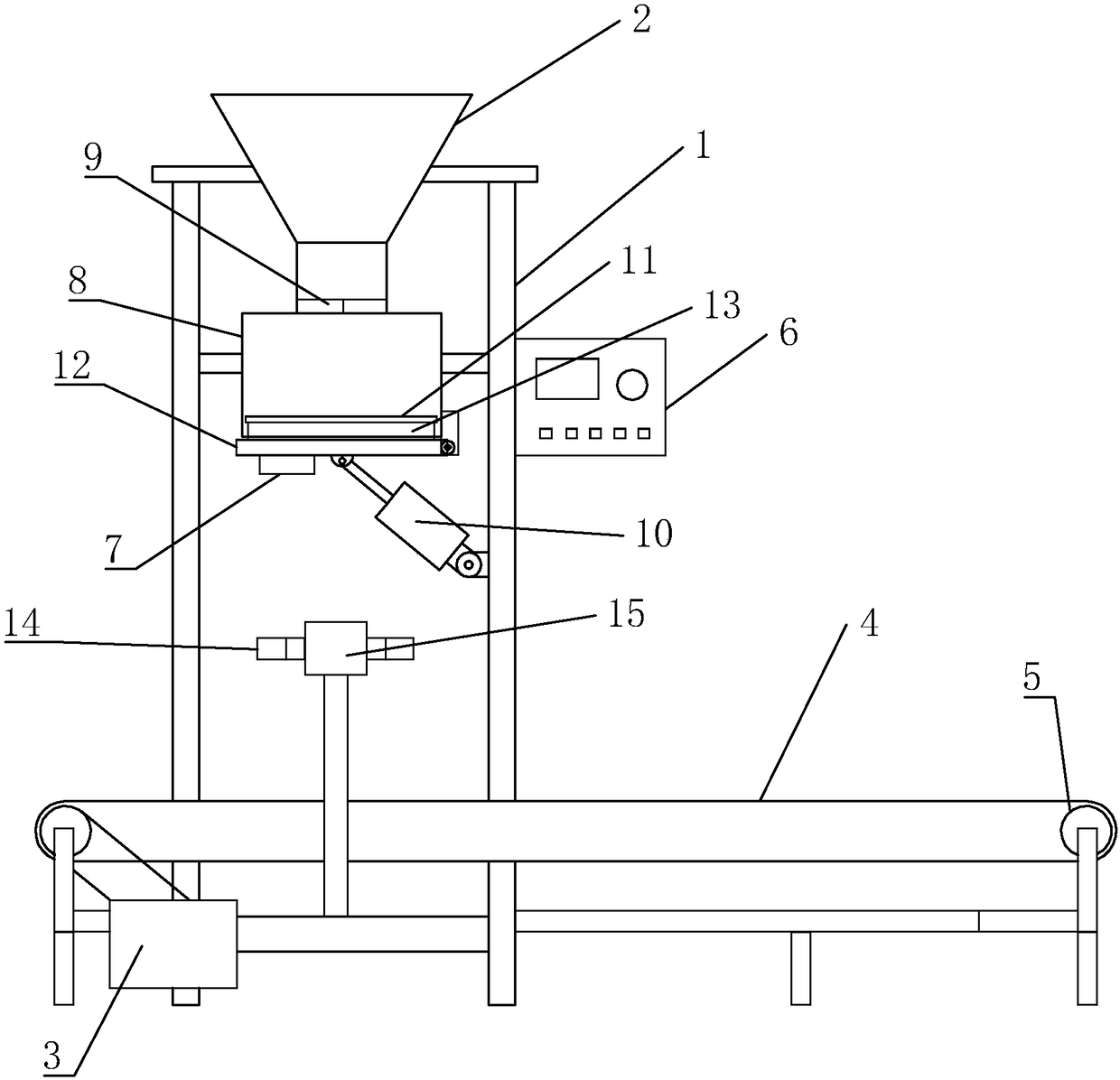

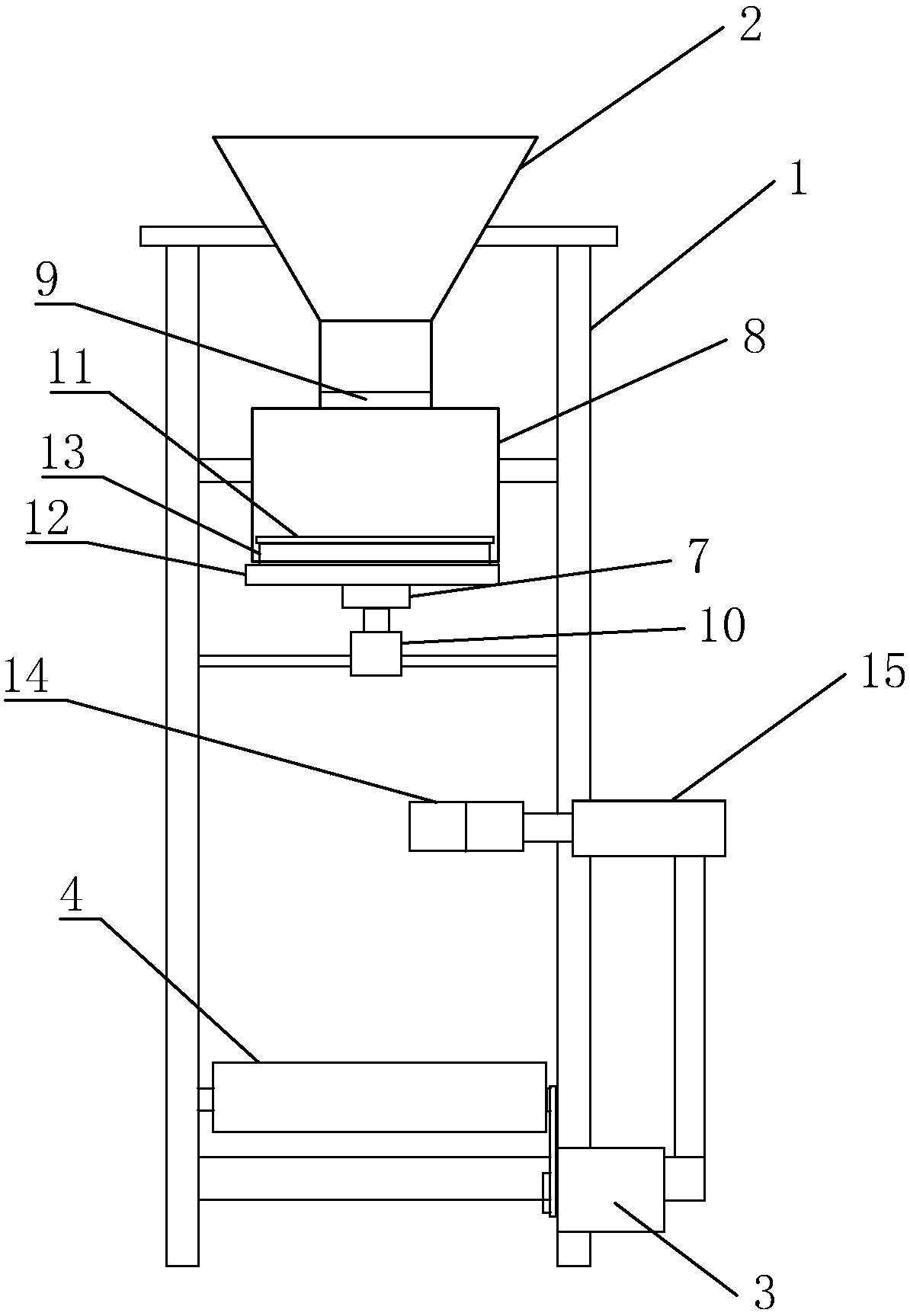

[0019] refer to Figures 1 to 2 As shown, a kind of granular feed weighing device of the present embodiment includes a body 1, a hopper 2, a motor 3, a conveyor belt 4, a roller 5, a controller 6, a weighing device and a positioning sensor 7, the receiving The hopper 2 is arranged on the machine body 1, and there are multiple rotating rollers 5, and the rotating rollers 5 are rotatably mounted on the body 1, and the conveyor belt 4 is sleeved on the rotating rollers 5, and can rotate on the rotating rollers 5 , the motor 3 is installed on the body 1, and the rotating shaft of the motor 3 is connected to the rotating roller 5, the weighing device is installed on the receiving hopper 2, and is located at the lower opening of the receiving hopper 2, and is connected to the cavity, the positioning sensor 7 is arranged at the lower end of the weighing device, and the signal output end of the positioning sensor 7 is connected to the first input end of the controller 6, and the signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com