Chain wheel conveyor

A sprocket conveyor and conveyor technology, applied in the field of mechanical transportation, can solve the problems of inconvenient installation and disassembly, time-consuming and laborious, etc., and achieve the effect of convenient maintenance, installation and disassembly, simple equipment structure and quick maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

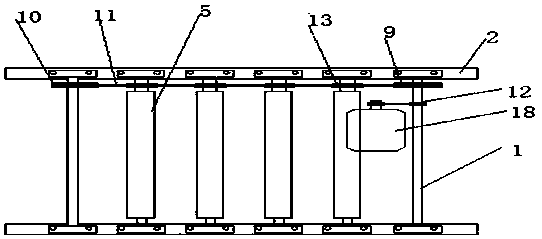

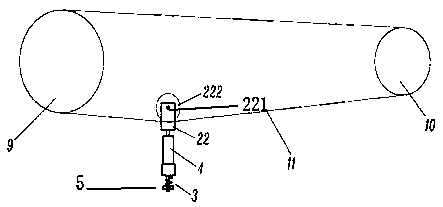

[0019] refer to figure 2 , a sprocket conveyor, comprising a conveyor bracket 2, a long chain 11, a transmission device and a plurality of idler rollers 5, one side end of the conveyor bracket is provided with a drive sprocket 9, and the other end of the opposite drive sprocket 9 A driven sprocket 10 is provided, and the driving sprocket 9 and the driven sprocket 10 are connected by a long chain 11. One end of the idler 5 is provided with a rotating sprocket 13, and the long chain 11 is placed at the bottom of the rotating sprocket 13, and is connected with the The rotating sprocket 13 is meshed, the two ends of the idler roller 5 are fixed on the conveyor bracket 2, the transmission device is connected with the driving sprocket 9, the transmission device includes a reduction motor 18, the main shaft 1 and the driving sprocket 12, and the main shaft 1 is fixed on the conveyor On the machine support 2, the drive sprocket 12 is arranged on the main shaft 1, and the reduction mo...

Embodiment 2

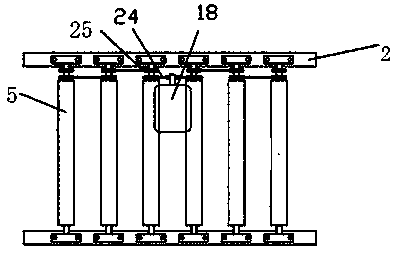

[0023] refer to Figure 4 , a sprocket conveyor in this embodiment, compared with Embodiment 1, has the following distinguishing technical features:

[0024] Both ends of the idler roller 5 are provided with rotating sprockets 13, both ends of the conveyor bracket 2 are provided with drive sprockets 9, and the opposite end of the drive sprocket 9 is provided with a pair of corresponding driven sprockets 10. Other structures are the same.

[0025] In the sprocket conveyor of this embodiment, since both ends of the idler rollers are equipped with rotating sprockets, which are simultaneously driven by the long chains arranged on both sides of the conveyor bracket, it is beneficial for the rotating sprockets at the ends of the idler rollers to rotate the long chain. The balanced distribution of the active force makes the idler roller rotate more smoothly, which significantly improves the conveying stability of the sprocket conveyor; and reduces the wear between the rotating sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com