Cargo circulation lifting method and electromagnetic power generation method of cargo circulation lifting

A cargo and electromagnetic technology, which is applied to conveyor objects, conveyor control devices, conveyors, etc., can solve the problems of difficult delivery of goods to a higher level, low operating efficiency, and difficulty in meeting the lifting and lowering requirements of goods, saving rotation time. , Improve the operating efficiency and facilitate the effect of lifting and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

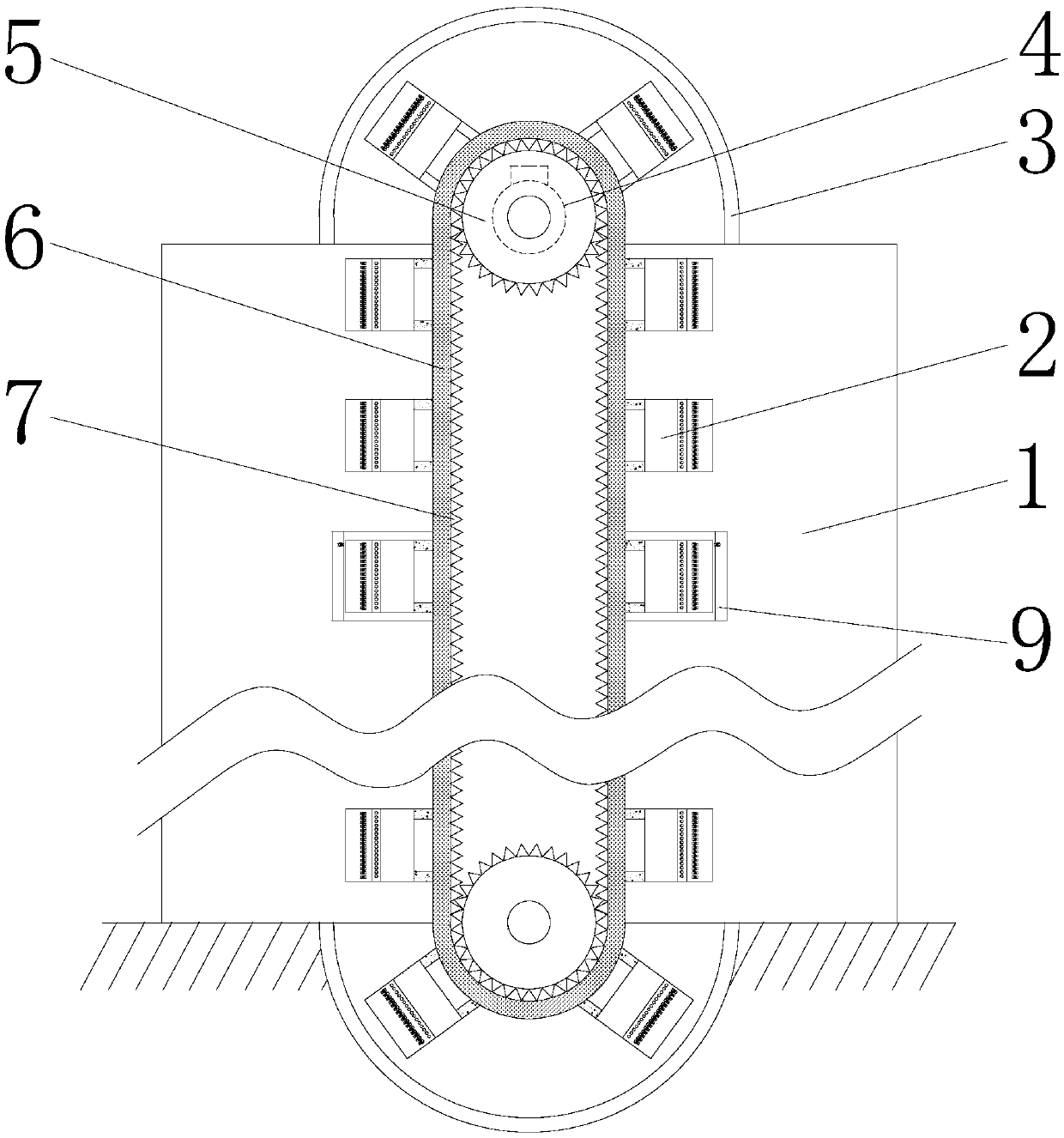

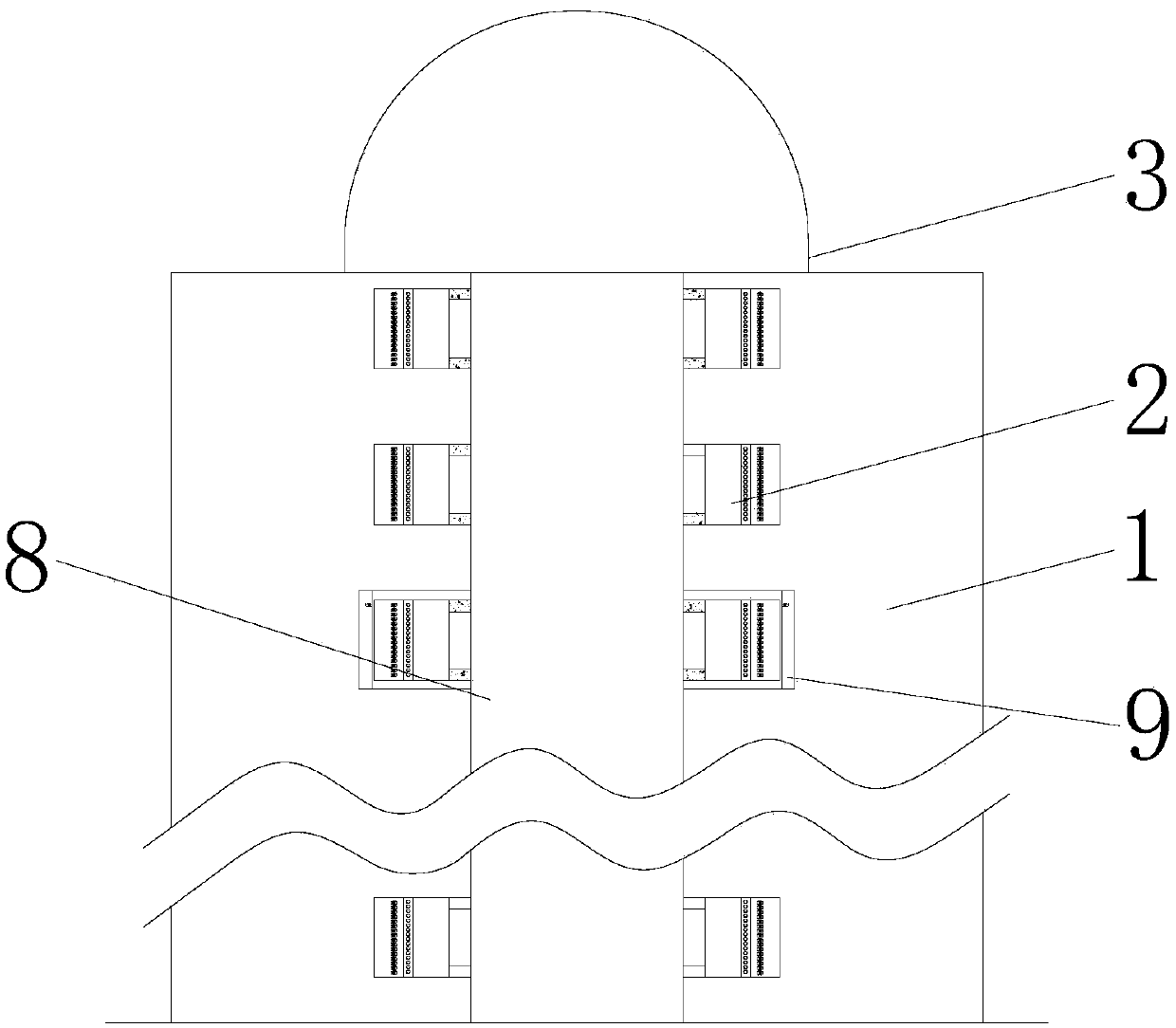

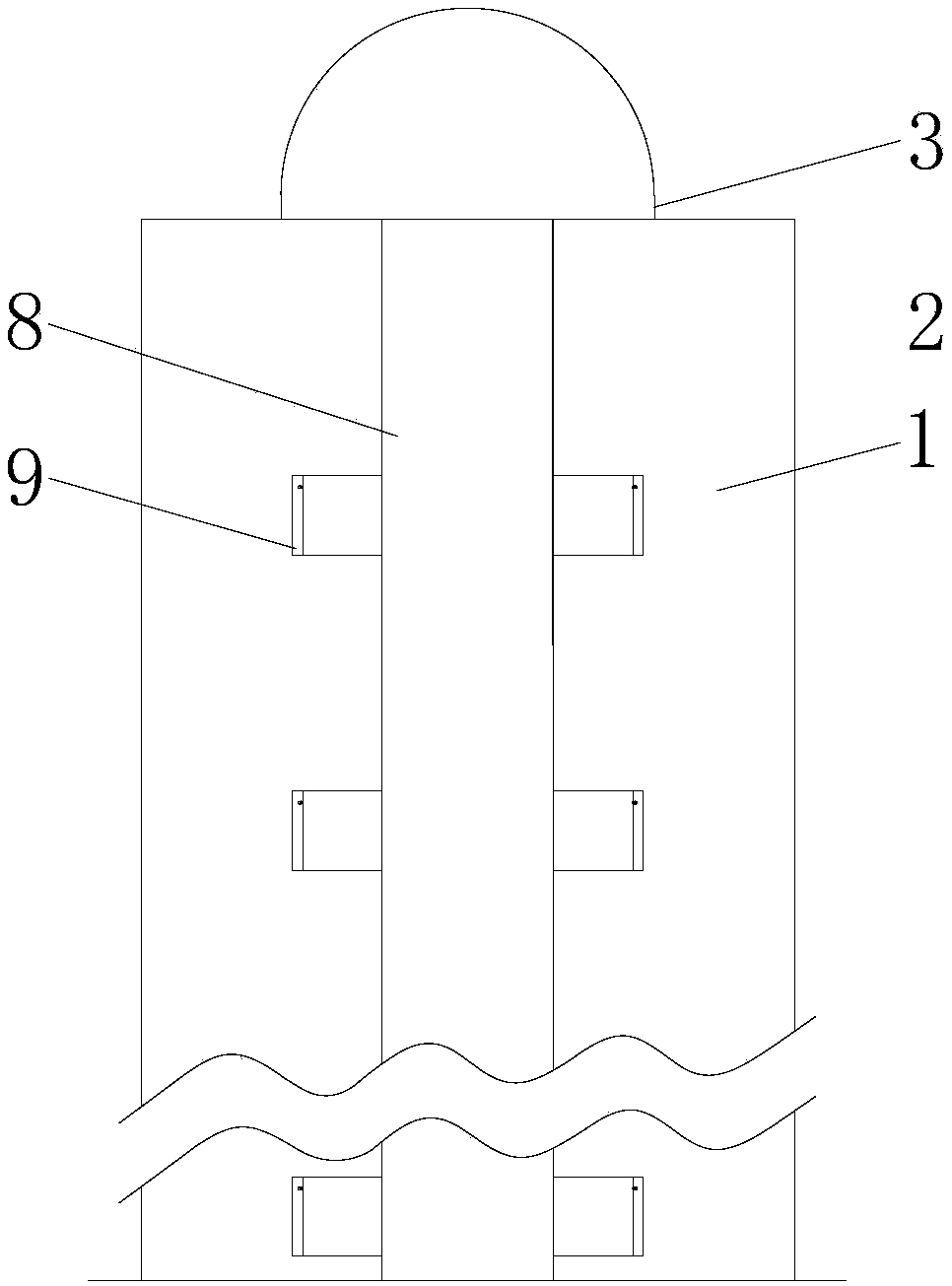

[0075] see figure 1 , figure 2 as well as image 3 , The device used in the cargo circulation lifting method of this embodiment is installed on the side of the building 1, and the cargo circulation lifting method is used to transport the goods located on one floor of the building 1 to another floor of the building 1. The cargo circulation lifting device includes a transmission mechanism, a detection mechanism, a controller, a strip-shaped protective box 8, two waterproof covers 3, and a plurality of storage mechanisms.

[0076] The transmission mechanism includes an endless transmission belt 6, a drive motor 4, and two runners 5. The driving motor 4 is installed on the end face of the top of the building 1, the output shaft is sheathed with a runner 5, and the other runner 5 is installed on the bottom of the building 1 in rotation. The rotating shaft of two runners 5 is perpendicular to the side of building 1, and the center line of two runners 5 is perpendicular to the gr...

Embodiment 2

[0111] see Figure 10 , Figure 11 as well as Figure 12 , on the basis of Embodiment 1, the cargo circulation lifting device of this embodiment is an embodiment of a drive circuit.

[0112] Each positioning switch circuit includes a photoelectric switch 12, a resistor R1, a current sensor H1, a delay switch module 1, and a manual switch S1 corresponding to a button 11. The transmitter of photoelectric switch one 12 is installed on the side of storage box 2, and the receiver of photoelectric switch one 12 is installed on the fixed plate 9 that is provided with on the side of the floor of corresponding building 1. The transmitter of photoelectric switch one 12, the same interface of receiver joins. One end of the resistor R1 is connected to the other interface of the transmitter of the photoelectric switch 12, and the other end is connected to the other interface of the receiver of the photoelectric switch 12. The output two ends of the current sensor H1 are respectively conn...

Embodiment 3

[0119] see Figure 13 On the basis of Embodiment 1, the cargo circulation lifting device of the present embodiment adds two guide strips 16 . The two guide strips 16 are parallel to each other and perpendicular to the ground, and the guide strips 16 are installed on the side of the building 1 . One side of the storage box 2 adjacent to the rubber column 10 is provided with a groove matching the guide bar 16 , so that the storage box 2 slides along the up and down direction of the guide bar 16 . The guide bar 16 can guide the lifting of the storage box 2, reduce the vibration of the storage box 2, and protect the goods in the storage box 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com