A quick connection method for prefabricated steel pipe-constrained steel concrete pier columns and cap beams

A quick connection and reinforced concrete technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve problems such as troublesome connection procedures, construction delays, high costs, and large construction sites, and achieves convenient and convenient lifting, installation and construction Quick and convenient hoisting, transportation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

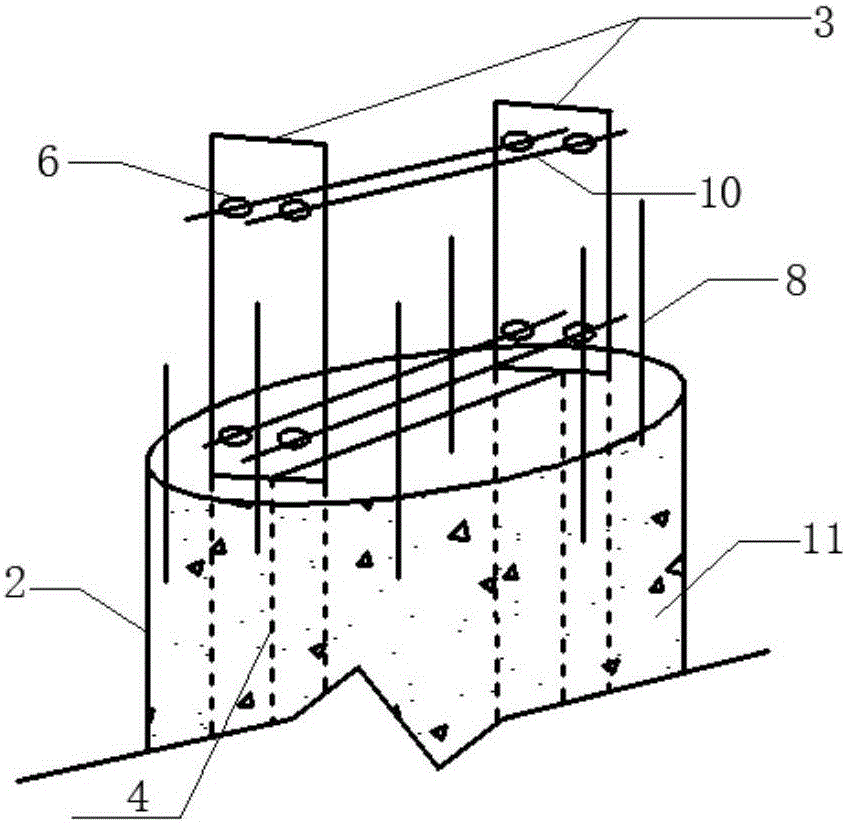

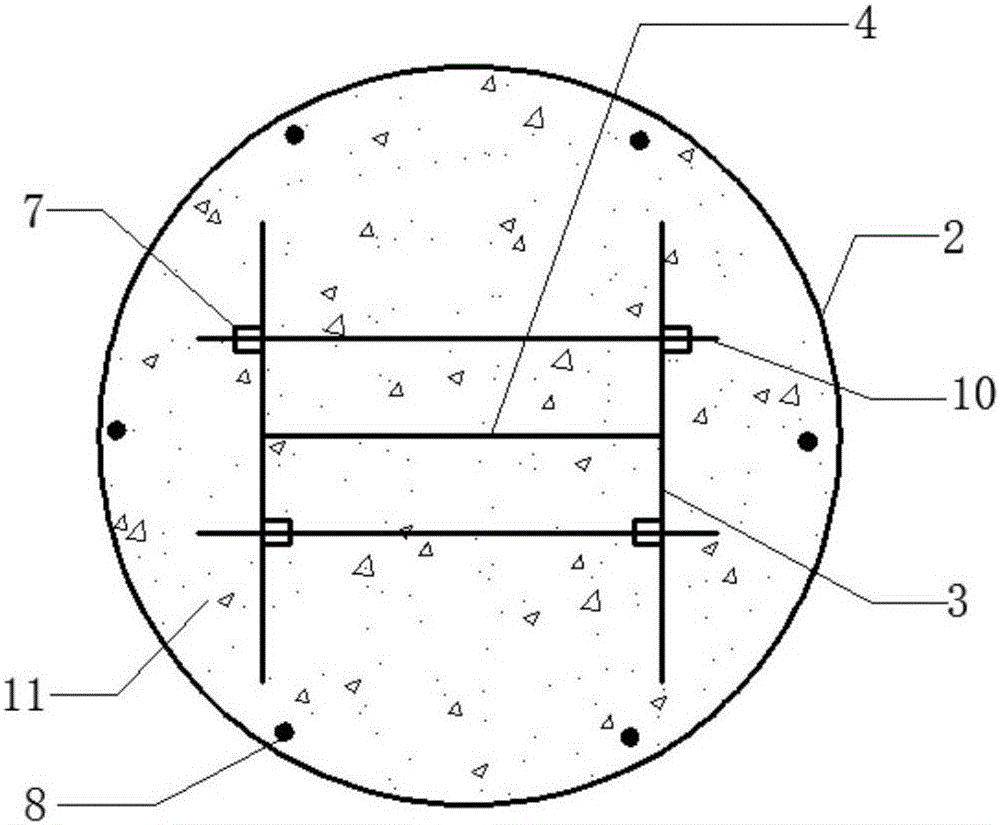

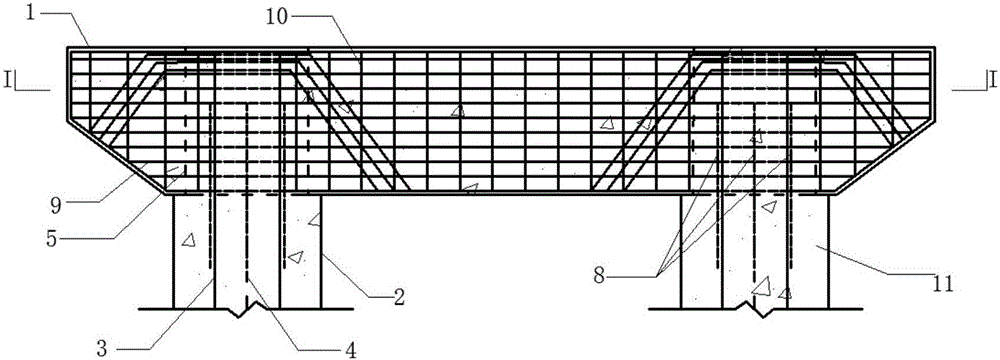

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-Figure 3 As shown, a method for fast connection of prefabricated steel pipe-constrained steel concrete pier columns and cover beams requires the use of reinforced concrete cover beams 1, peripheral steel pipes 2, built-in steel flanges 3, built-in steel webs 4, openings Tenon 7, pre-embedded steel bar 8 connecting the top of the pier column, longitudinal steel bar 9, transverse steel bar 10 and steel pipe bound concrete 11. The longitudinal erection structural steel bars and stressed steel bars in the reserved holes of the reinforced concrete cover beam 1 cannot be cut off, and the transverse steel bars 10 should be properly avoided, bent or passed through the anchor holes 6 of the built-in steel flange 3 according to the width of the steel flange. .

[0024] A hole 5 is reserved at the position corresponding to the pier of the prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com