Assembly-type temporary road plate

A temporary road, prefabricated technology, applied in the direction of roads, roads, paving with prefabricated blocks, etc., can solve the problems of large construction waste, waste of construction resources, increased difficulty, etc., to achieve strong roads, high turnover, economical Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

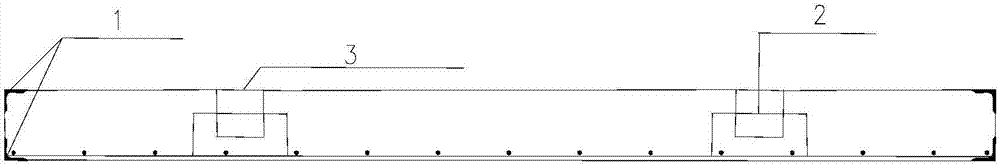

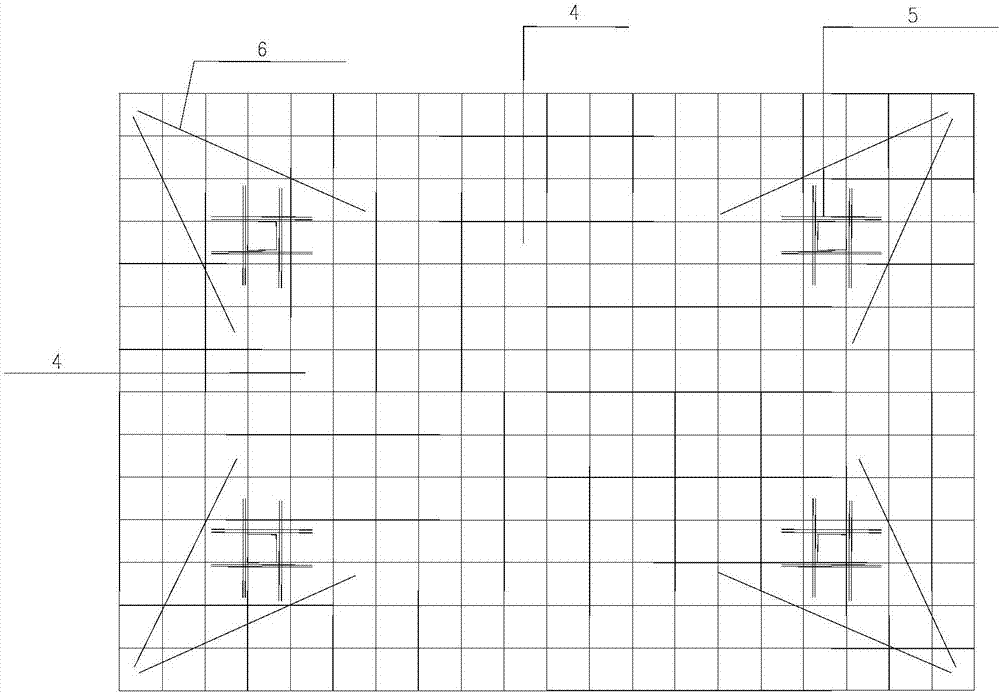

[0016] Such as Figure 1-3 Shown, the specification of the present invention is 3m * 2.1m * 0.15m, comprises the suspension ring 2 that L50 * 3 side protection angle steel 1,20 round steels are made, 100 * 100 * 100 hoisting opening 3 and its internal reinforced concrete composition, and its internal reinforcement Including stress reinforcement 4, hole reinforcement 5 and radial reinforcement 6, among which, the stress reinforcement is φ16@150, the hole reinforcement is 32 16mm reinforcement bars, L=500mm, and the radial reinforcement is 8 16mm reinforcement bars, L=500mm , all of which are grade 3 steel. During production, L50×3 edge protection angle steel 1 is required to be firmly welded, and stress reinforcement 4, opening reinforcement rib 5 and radial reinforcement 6 are laid, and welded with L50×3 edge protection angle steel 1, and lifting ring 2 is installed. , install 100×100×100 hoisting mouth 3 formwork, use C35 concrete pouring, standard maintenance, and require th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com