Span tower type cable crane crown block and mating cable saddle

A cable crane and cross-tower technology, applied in cable cranes, hoists, walking mechanisms, etc., can solve problems such as passing through, and achieve the effects of ingenious design, high operational feasibility and safety, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

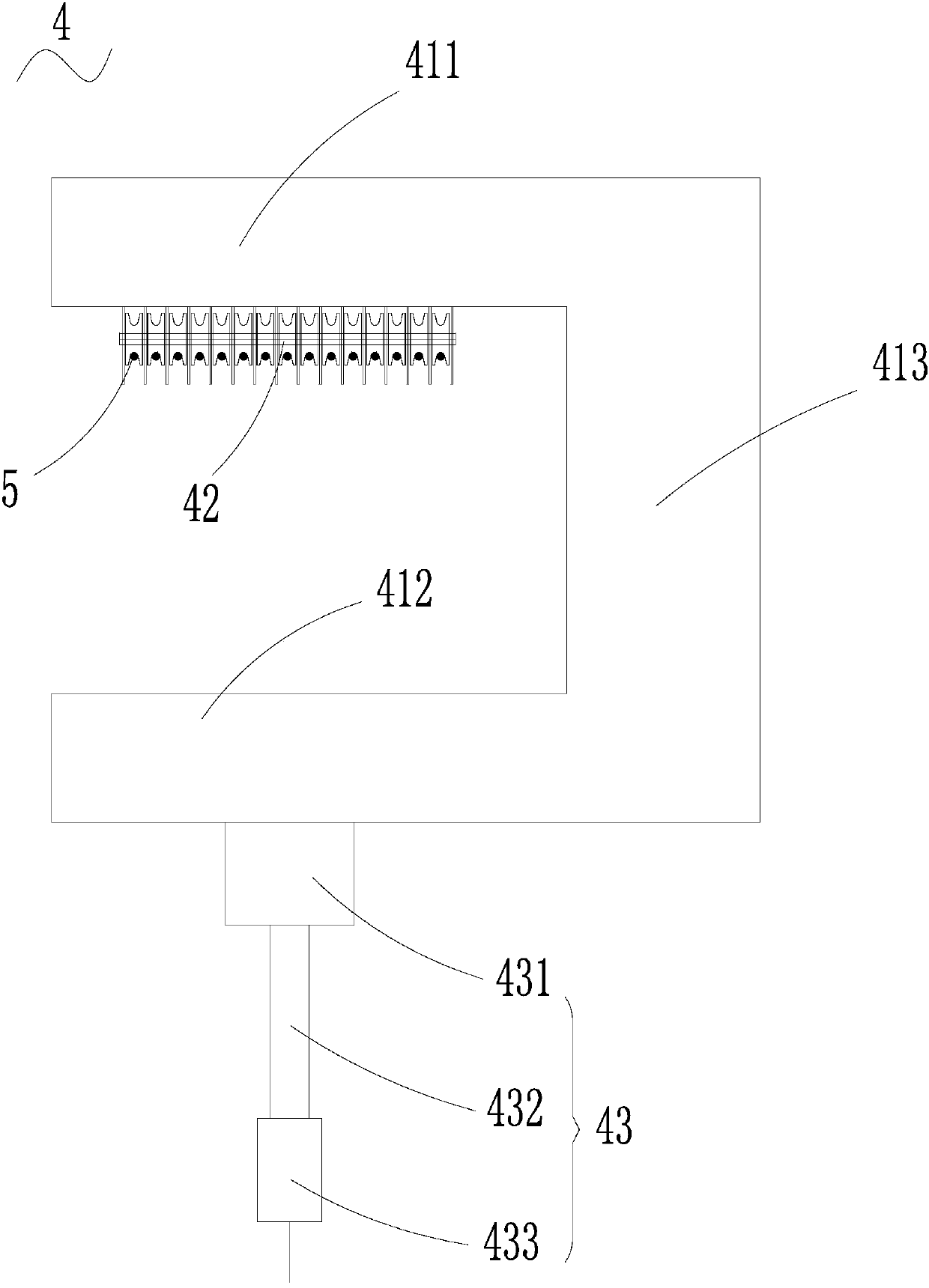

[0045] Such as figure 1 As shown, the overhead crane of the straddle-tower cable crane in this embodiment, the overhead crane 4 of the straddle-type cable crane includes a sports car part, a hoisting part, and a crane longitudinal beam 413, and the sports car part includes a first crane crossbeam 411 and is installed on the first crane beam 413. The sports car axle assembly 42 at the bottom of the crown beam 411, the sports car axle assembly 42 can be supported on the load-bearing cable of the cable crane and move back and forth along the extension direction of the load-bearing cable; the sports car axle assembly 42 can be lifted under the action of an external force to break away from the load-bearing cable; The hoisting part includes the second-day car beam 412 and the lifting assembly 43 installed at the bottom of the second-day car beam 412, the first crown car beam 411 is located above the second-day car beam 412, and the crown car longitudinal beam 413 is connected to the...

Embodiment 2

[0064] The structure of the crown block 4 of the cross-tower cable crane in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

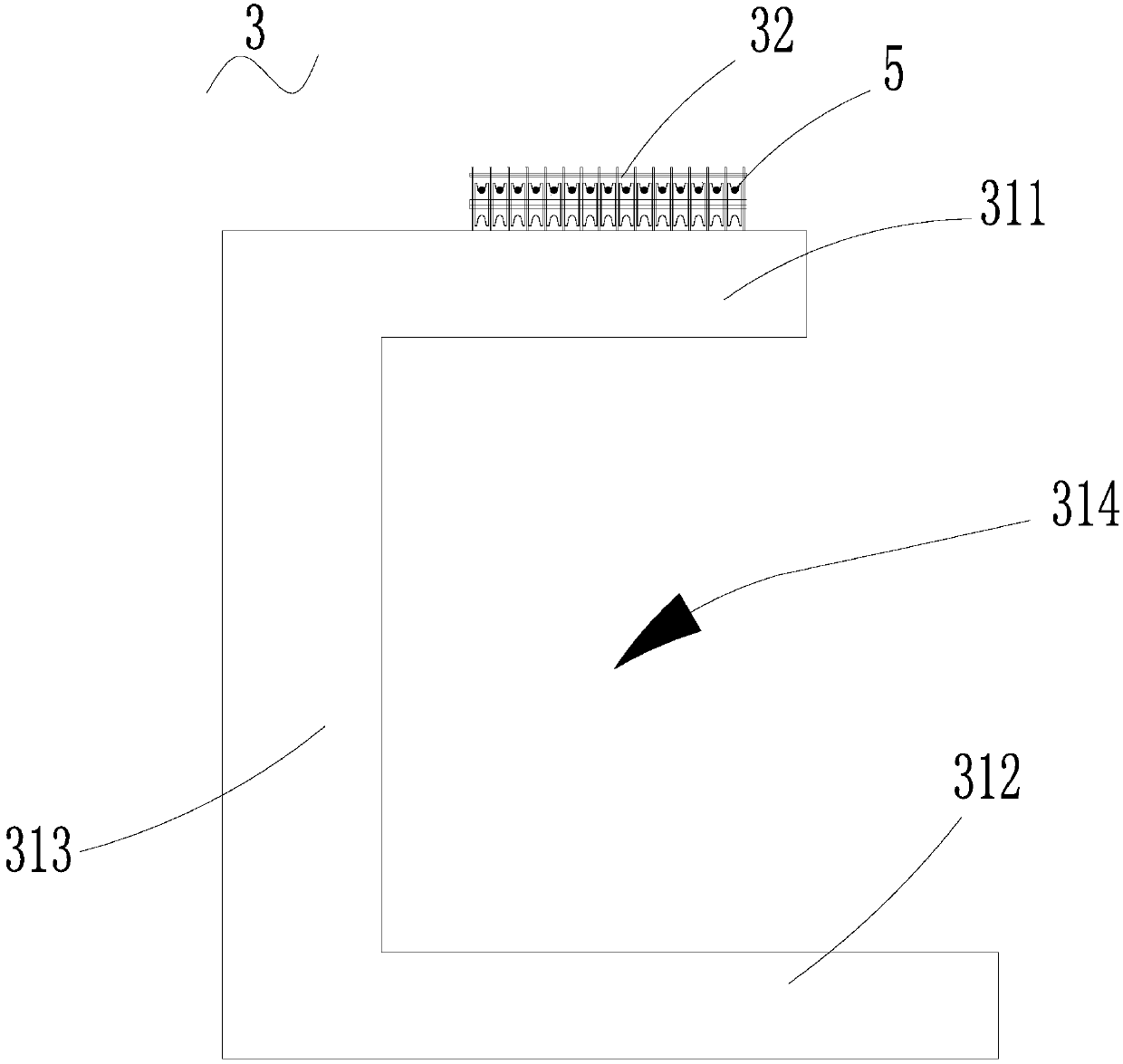

[0065] Such as Figure 5 As shown, the structure of the cable crane saddle 3 of the present embodiment matched with the above-mentioned cross-tower cable crane crane is basically the same as that of the cable crane saddle 3 of the embodiment 1. The difference is that in this embodiment, the first The cable saddle crossbeam 311 is located below the second cable saddle crossbeam 312, and the C-shaped groove of the second C-shaped member not only accommodates the support part, but also has an escape space 315 for the sports car part to pass through.

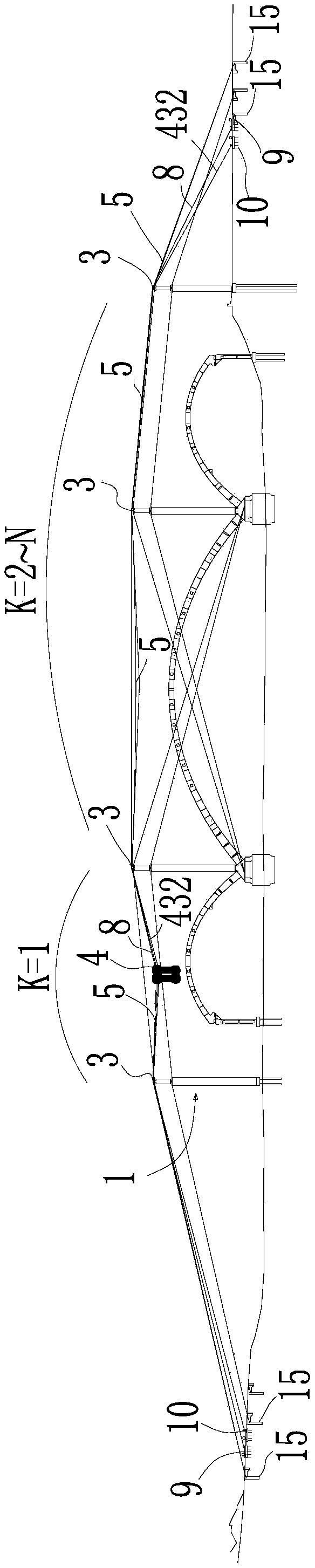

[0066] Such as Image 6 As shown, the bridge crane 4 of the straddle-tower cable crane of this embodiment and the supporting cable crane saddle 3 are installed in the multi-span tower cable crane, and the four-tower three-span suspension cable crane includes load-bearing c...

Embodiment 3

[0076] The structure of the overhead crane 4 of the cross-tower cable crane in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0077] Such as Figure 7 As shown, the cable crane saddle 3 of the present embodiment matched with the above-mentioned span-tower cable crane crane is basically the same in structure as the cable crane saddle 3 of the embodiment 1, and the difference lies in: the first cable saddle crossbeam 311, The cable saddle longitudinal beam 313 and the second cable saddle cross beam 312 form an I-shaped member, that is, the I-shaped member has two C-shaped grooves 314 with openings facing away from them, and the cable crane saddle 3 is provided with two A load-bearing cable pulley assembly 32, and two load-bearing cable pulley assemblies 32 are respectively arranged at both ends of the top of the first cable saddle beam 311 along the length direction.

[0078] In this embodiment, there are two cable saddle longitudinal beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com