Self-compacting concrete and preparation method thereof

A kind of self-compacting concrete and concrete technology, applied in the field of concrete, can solve the problems of unfavorable durability of concrete structure, relatively high requirements for raw material selection, increase of project cost, etc., and achieve the goal of improving appearance quality, easily obtaining local materials, and improving crack resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

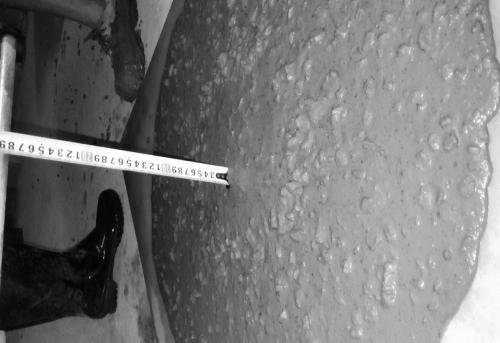

Image

Examples

Embodiment 1

[0030] A self-compacting concrete comprising the following components in parts by weight:

[0031] 1 part of cement, 0.49 parts of water, 2.05 parts of sand, 2.6 parts of stone, 0.27 parts of fly ash, 0.10 parts of expansion agent, and 0.015 parts of admixture.

[0032] The preparation process is:

[0033] 1) Clean the raw material stones and stack them in a wet and no clear water condition. Cement and fly ash must be stored in the warehouse for no less than 3 days, so that the internal temperature is close to the external temperature;

[0034] 2) Put the admixture into the water and mix it for later use, put the sand and stone into the mixer and mix it for 20s, put the powder into the mixer and mix it with the sand and gravel for 20s; finally add the mixture of the admixture and water into the mixer and mix it for 120s, to obtain self-compacting concrete.

[0035] The resulting self-compacting concrete has poor fluidity, insufficient patina and slight bleeding.

Embodiment 2

[0037] A self-compacting concrete comprises the following components in parts by weight: 1 part of cement, 0.49 part of water, 2.11 parts of sand, 2.55 parts of stone, 0.27 part of fly ash, 0.10 part of expansion agent and 0.014 part of admixture.

[0038] The preparation process is:

[0039] 1) Clean the raw material stones and stack them in a wet and no clear water condition. Cement and fly ash must be stored in the warehouse for no less than 3 days, so that the internal temperature is close to the external temperature;

[0040] 2) Put the admixture into the water and mix it for later use, put the sand and stone into the mixer and mix it for 20s, put the powder into the mixer and mix it with the sand and gravel for 20s; finally add the mixture of the admixture and water into the mixer and mix it for 140s, to obtain self-compacting concrete.

[0041] Compared with Example 1, the obtained self-compacting concrete has appropriately increased the sand rate, reduced the amount o...

Embodiment 3

[0043] A self-compacting concrete comprises the following components in parts by weight: 1 part of cement, 0.49 part of water, 2.11 parts of sand, 2.55 parts of stone, 0.28 part of fly ash, 0.09 part of expansion agent and 0.013 part of admixture.

[0044] The preparation process is:

[0045] 1) Clean the raw material stones and stack them in a wet and no clear water condition. Cement and fly ash must be stored in the warehouse for no less than 3 days, so that the internal temperature is close to the external temperature;

[0046] 2) Put the admixture into the water and mix it for later use, put the sand and stone into the mixer and mix it for 20s, put the powder into the mixer and mix it with the sand and gravel for 20s; finally add the mixture of the admixture and water into the mixer and mix it for 130s, to obtain self-compacting concrete.

[0047] The obtained self-compacting concrete is compared with Example 2. Under the condition of constant water-binder ratio, the amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com