Welding protective sleeve and magnetic suspension axial bearing

A technology for axial bearings and protective sleeves, applied in the direction of magnetic bearings, shafts and bearings, bearings, etc., can solve problems such as excessive solder, electrical safety, etc., and achieve the effect of avoiding short circuits and improving electrical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

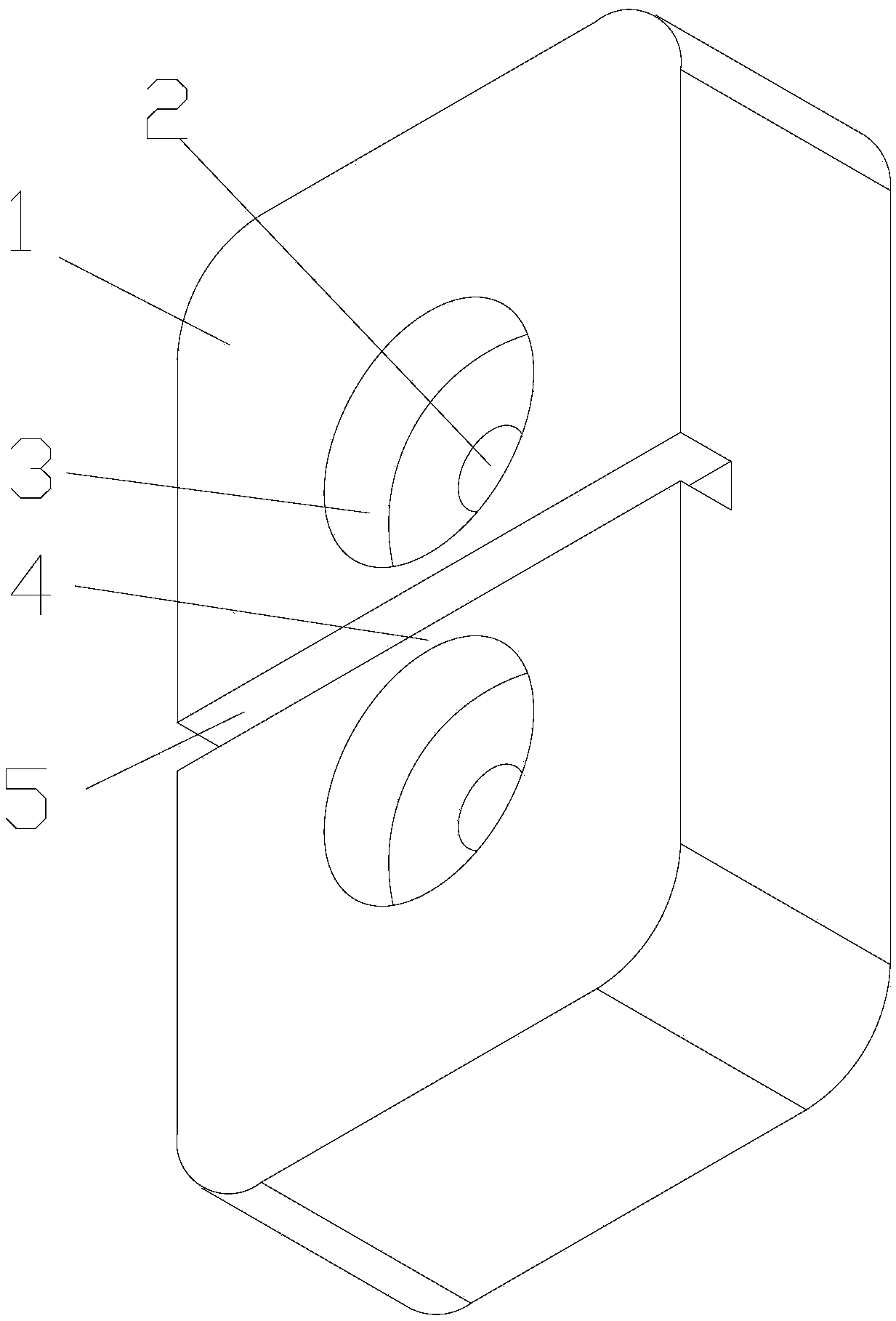

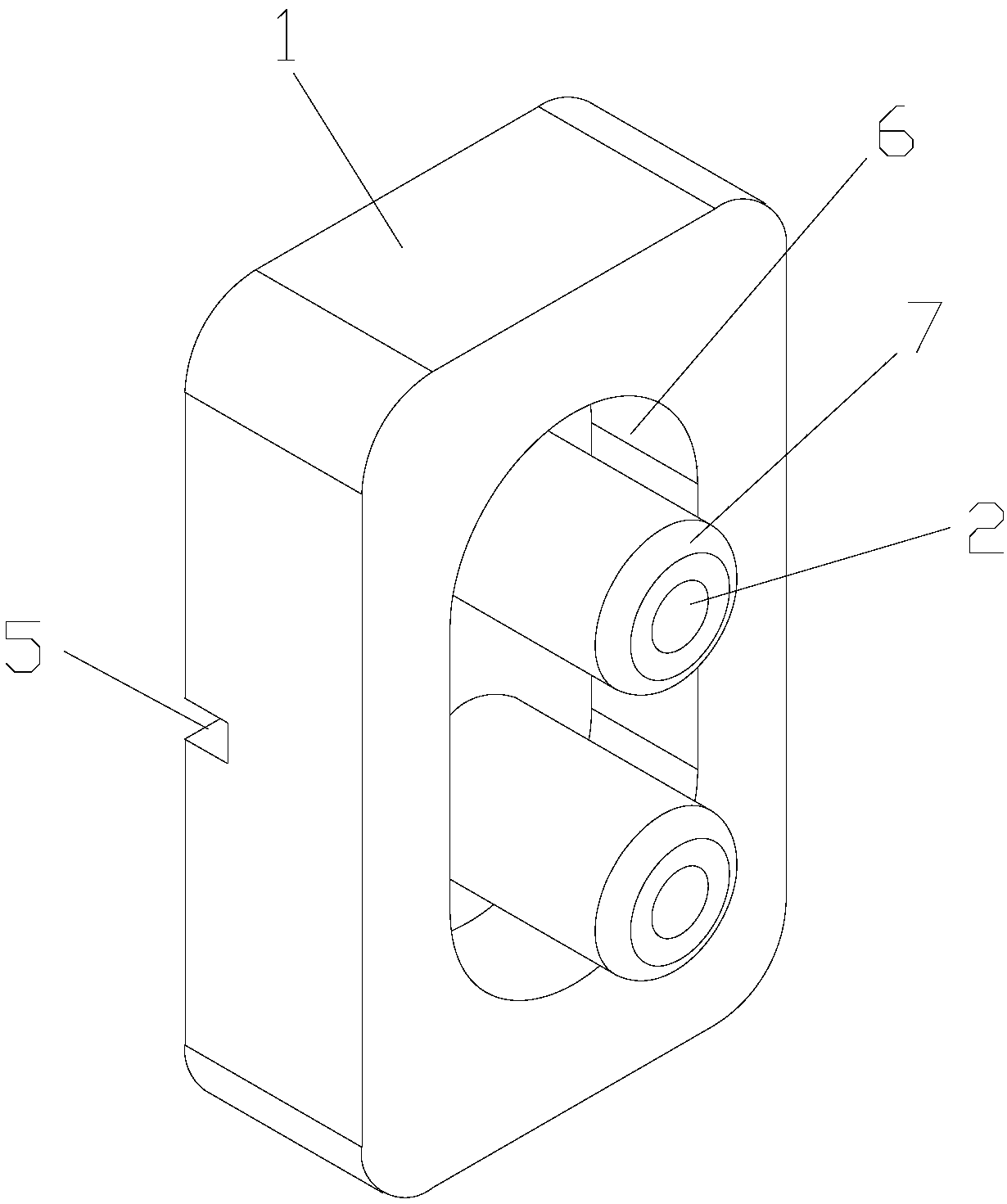

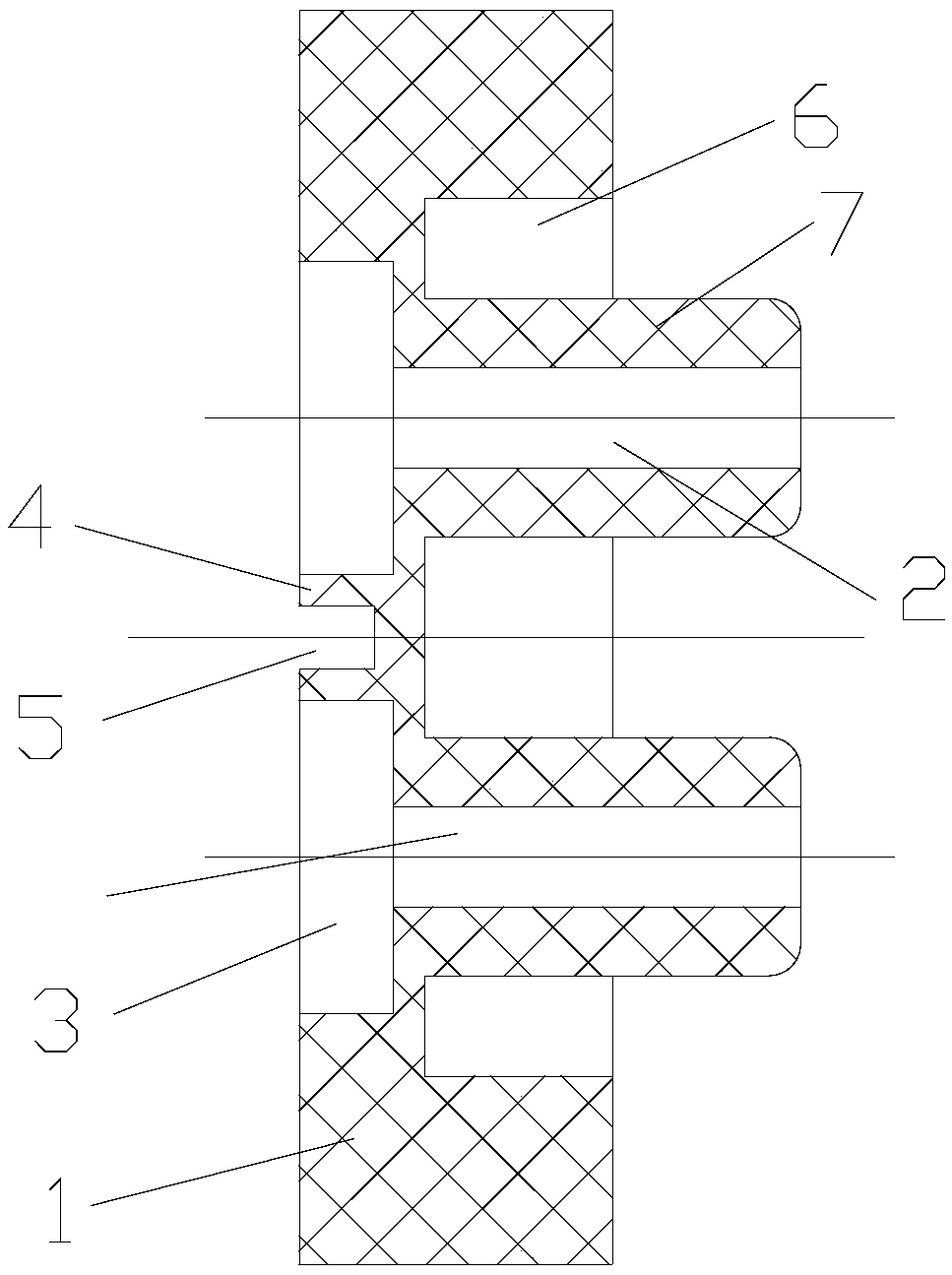

[0030] see in conjunction Figure 1 to Figure 11 As shown, according to the embodiment of the present invention, the welding shield includes a body 1, on which a wire hole 2 for leading out wires 11 is provided, and a counterbore 3 is provided on the side of the wire outlet end of the wire hole 2.

[0031] The counterbore 3 can form a space for solder. When the lead-out wire 11 passes through the wire hole 2 and the PCB board 9 for soldering, the counterbore 3 can form enough solder space at the bottom of the PCB 9, and the solder will flow into the counterbore. 3, the welding time will not be long due to the lack of space at the bottom, and the solder will not diffuse and flow to the surrounding area due to excessive solder, avoiding the short circuit and insufficient creepage distance caused by poor welding of the magnetic levitation axial bearing, and improving the magnetic levitation axial bearing. Electrical safety of bearings. The solder is, for example, solder.

[003...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap