An optical fiber light emitting structure, manufacturing device and manufacturing method thereof

A light-emitting structure and optical fiber technology, which is applied to lighting devices, lighting device light guides, lighting device components, etc., can solve the problems of lack of fiber optic cable wiring, single fiber wiring structure, waste of fiber light sources, etc., and achieve uniform light and wiring. Clear, Efficient Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In order to make the technical means, creative features, goals and effects of the present invention easier to understand, the present invention will be further described below in conjunction with specific embodiments.

[0032] An optical fiber light-emitting structure, comprising a reflective sheet 4, an optical fiber layer 3 arranged on the reflective sheet 4, a diffusion sheet 1 arranged on the optical fiber layer 3, and a light source 5 connected to the optical fiber layer 3; the optical fiber layer 3 is a guide Composition of optical fibers.

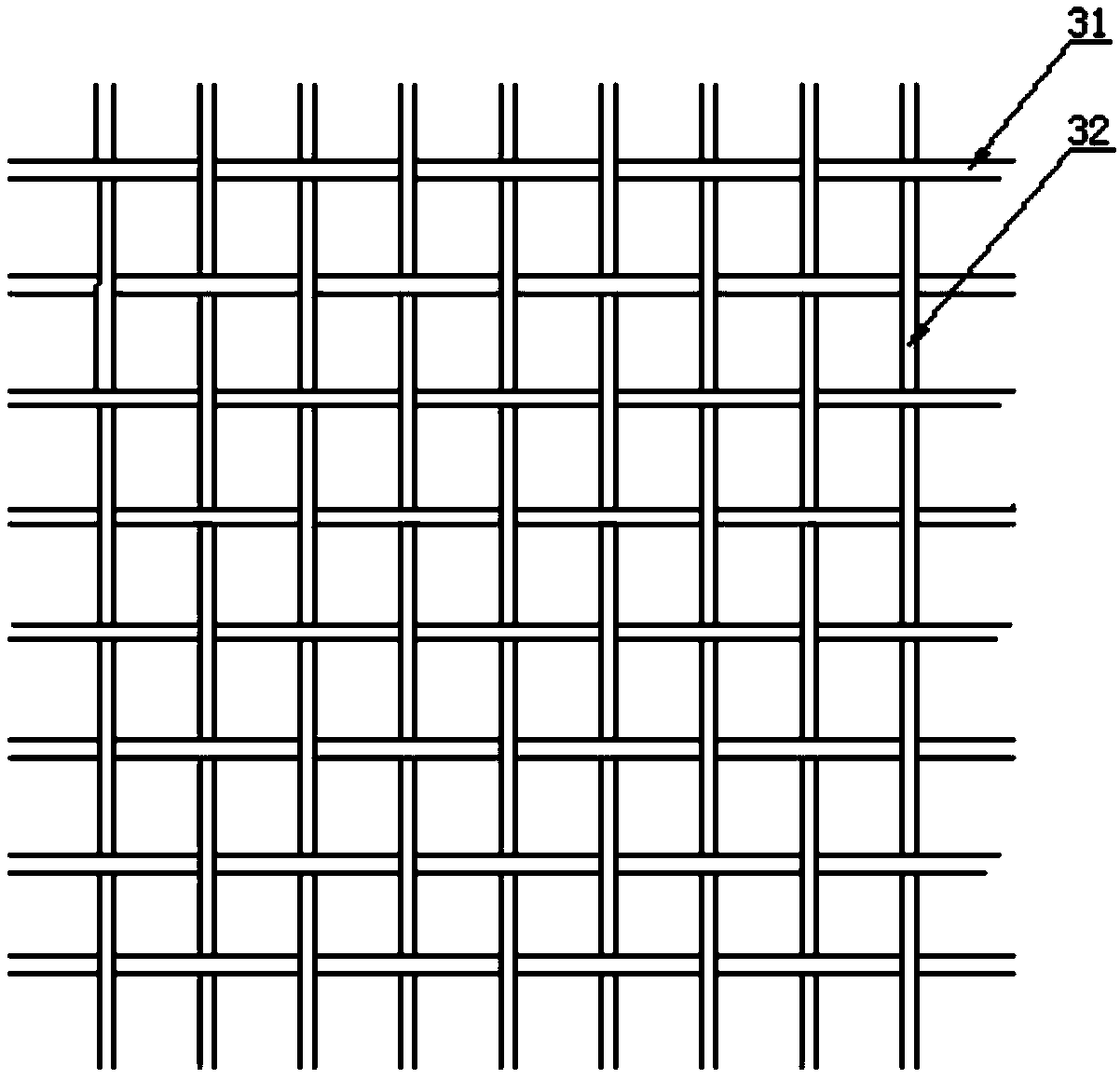

[0033] Specifically, the arrangement of the light-guiding optical fibers in the optical fiber layer 3 is further optimized, that is, transverse optical fibers 31 and longitudinal optical fibers 32 are planned, and the transverse optical fibers 31 are parallel to each other, similarly, the longitudinal optical fibers 32 parallel to each other.

[0034] Wherein, the number of optical fiber bundles and the number of optical fibe...

Embodiment 2

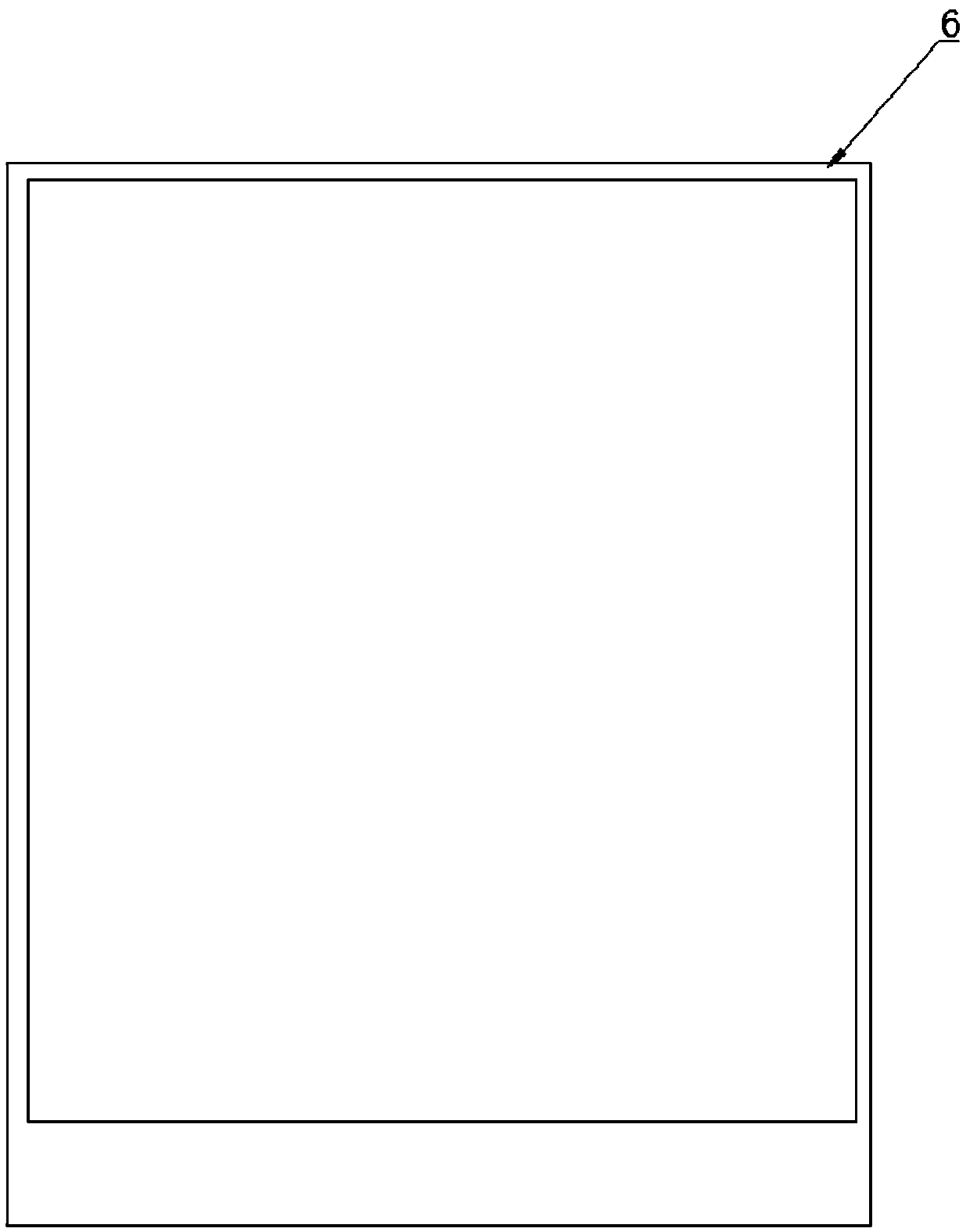

[0041] This embodiment is a manufacturing device and manufacturing method of an optical fiber light-emitting structure in Embodiment 1; specifically, the manufacturing device is an optical fiber braided frame 6, such as image 3 As shown, it includes an upper frame 61 and a lower frame 62; the upper frame 61 is connected to the bottom edge of the lower frame 62 and forms an angle α between the upper frame 61 and the lower frame 62, and the angle α is 10-30°, specifically, its side is as Figure 4 shown.

[0042] Further, a manufacturing method of an optical fiber light-emitting structure based on the optical fiber braided frame 6 includes the following steps:

[0043] (1) take the optical fiber braiding frame 6 and some optical fibers for use;

[0044] (2) Take some optical fibers from the angle α formed by the upper frame 61 and the lower frame 62 and insert them into the light weaving frame 6 in parallel longitudinally, so that the optical fibers are positioned above the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com