Spray nozzle scratch protecting device and humidifier comprising same

A technology for humidifiers and nozzles, which is applied in the field of humidifiers and nozzle anti-spraying devices. It can solve the problems such as the difficulty of cleaning dripping nozzles, and achieve the effect of remarkable humidification effect, labor saving and high cleaning efficiency.

Pending Publication Date: 2018-12-28

王育辉

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The object of the present invention is to provide an anti-spraying device for the nozzle, which is used to solve the problems of water dripping at the nozzle due to the attachment of textile flying flowers, dust, dust, etc. and the difficulty of cleaning the nozzle; Humidifier for anti-blooming device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

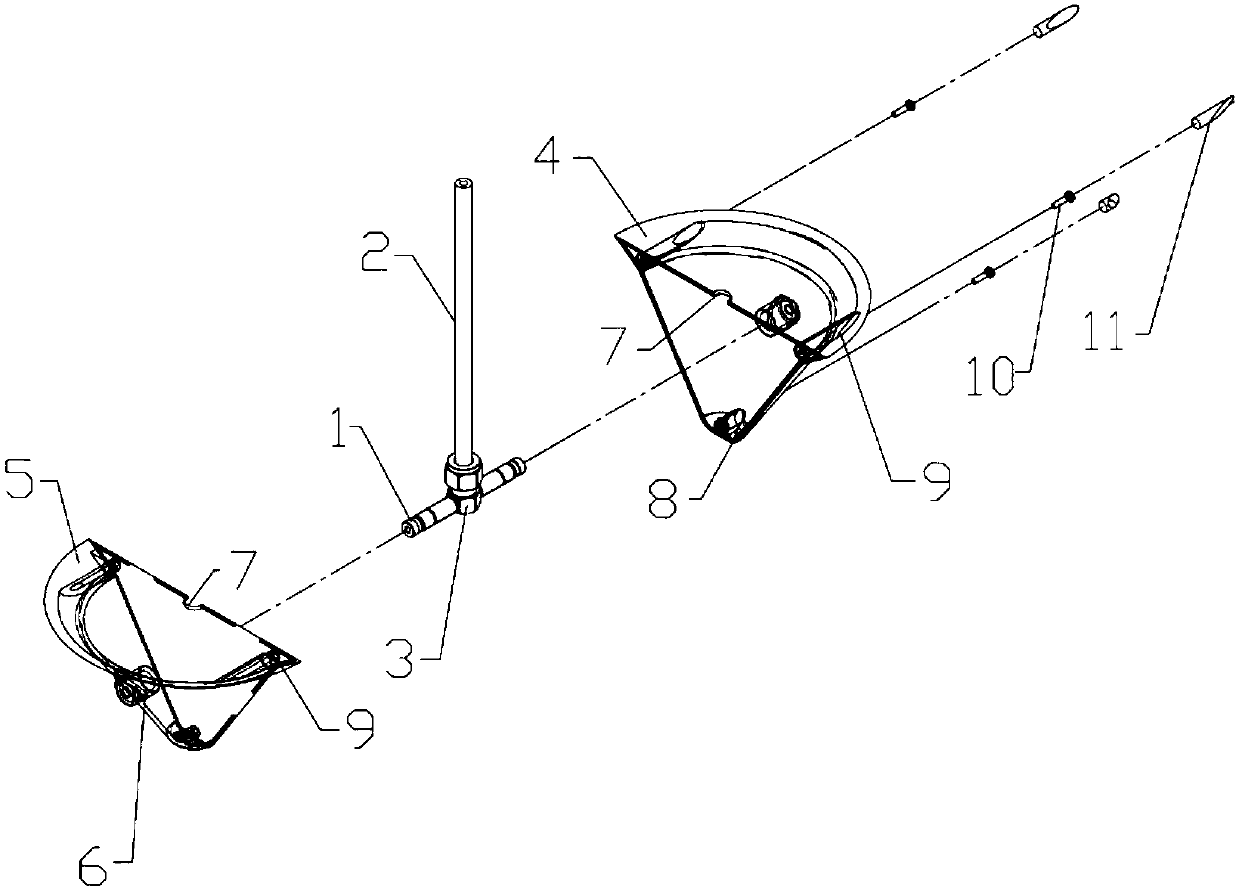

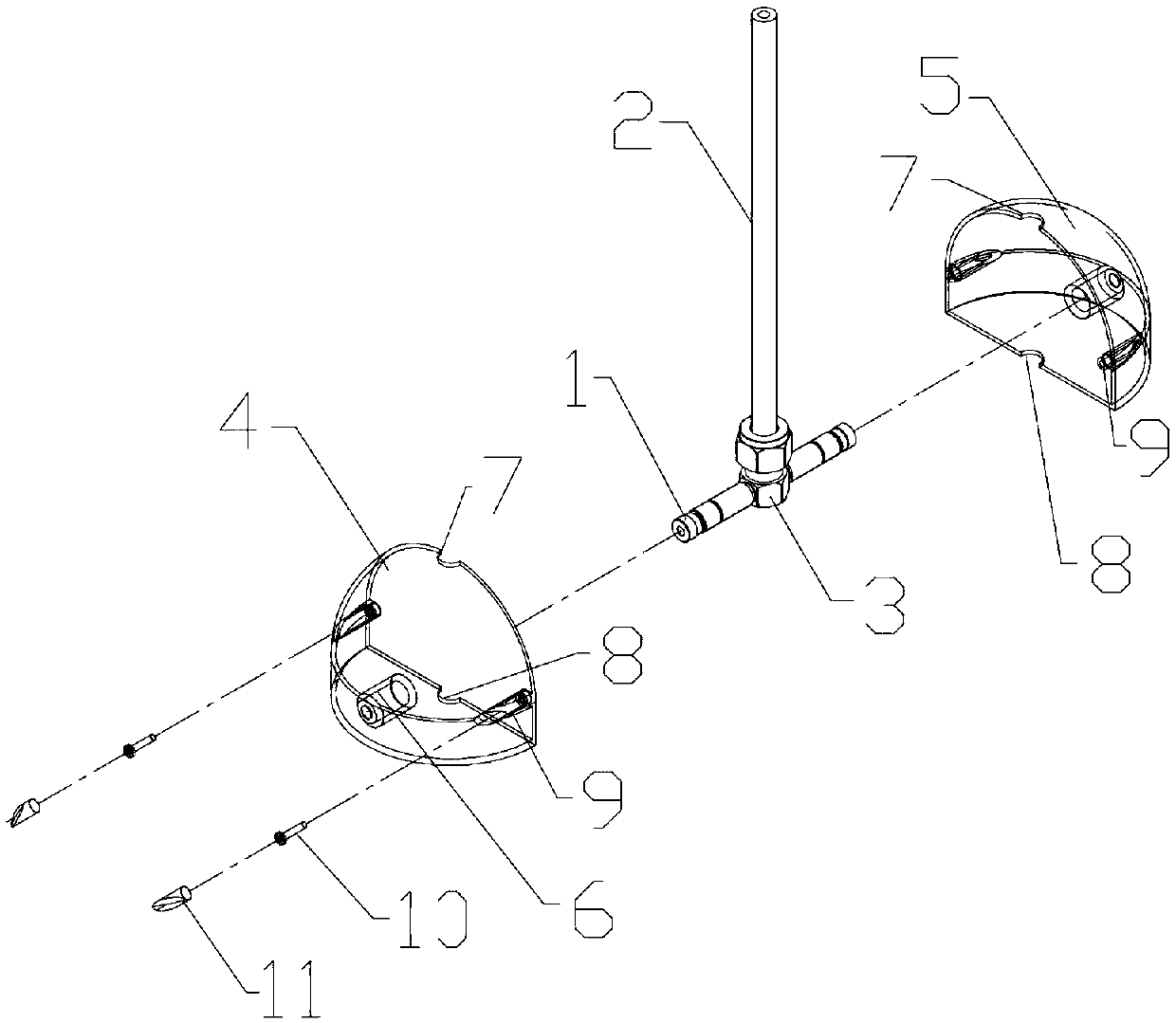

The invention relates to a spray nozzle scratch protecting device and a humidifier comprising the same. The humidifier comprises a water delivery structure; the water delivery structure comprises a high-pressure pipe, a spray nozzle, a connector arranged between the high-pressure pipe and the spray nozzle and the spray nozzle scratch protecting device; the spray nozzle scratch protecting device comprises a housing, the housing comprises more than two shells for enclosing a closed space outside the connected part between the spray nozzle and the high-pressure pipe; every shell is provided witha shell connecting structure in detachable connection with neighboring shells; the top of the housing is provided with a pipe inlet for yielding the high-pressure pipe, the side wall of the housing isprovided with a connecting sleeve for connecting the spray nozzle, the inner orifice of the connecting sleeve is used for inletting the spray nozzle, the outer orifice of the connecting sleeve is used for the spray nozzle to spray out, the spray orifice of the spray nozzle is formed inside the connecting sleeve, and between the outer circumferential surface of the spray nozzle and the inner surface of the connecting sleeve is sealed. The spray nozzle scratch protecting device can avoid dripping water due to textile flying attached to the spray nozzle, achieve significant humidifying effects and reduce the cleaning difficulty.

Description

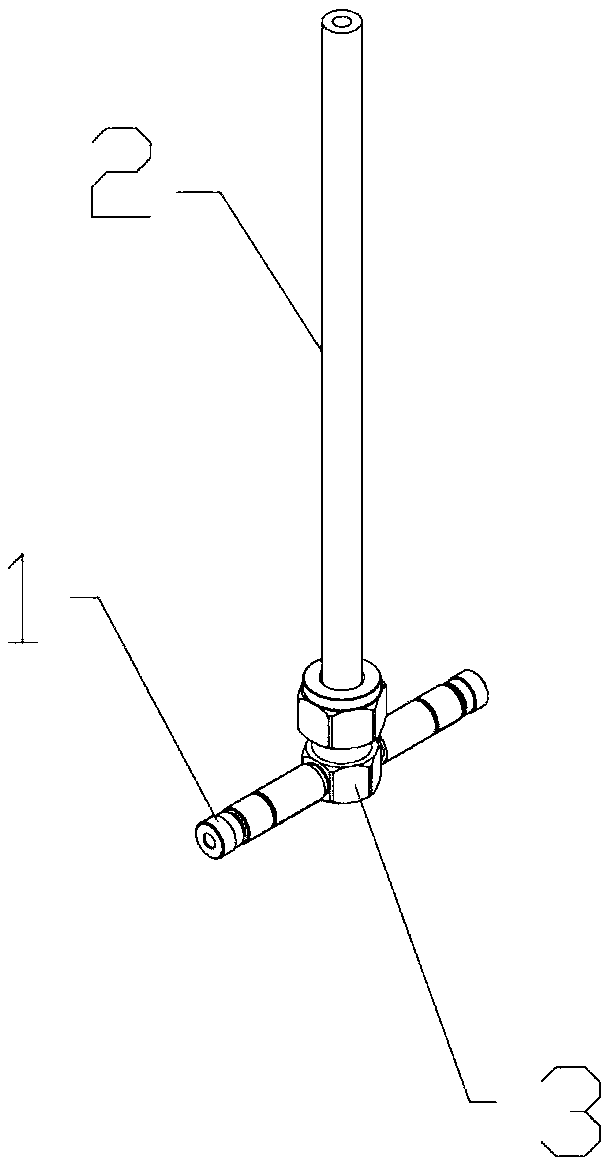

technical field The invention relates to a spray head anti-spray device and a humidifier using the device. Background technique Humidifiers have a wide range of applications and can be used in the textile industry, cotton processing industry, carton production industry, edible fungus industry, weaving industry, fog forest industry, etc. Among them, the textile industry requires a certain humidity in the textile process, and the relative humidity is at Between 65-75%, the strength of cotton yarn is close to its maximum value, effectively preventing the possibility of yarn breakage. As shown in Figure 1, a general humidifier includes a nozzle 1, a high-pressure pipeline 2, and a valve connection device 3 connected between the nozzle and the high-pressure pipeline. The nozzle is connected to the high-pressure pipeline 2 through the valve connection device 3, and the high-pressure pipeline 2 is Extending up and down, the valve connection device 3 is installed at the lower end o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24F6/14F24F6/00

CPCF24F6/00F24F6/14

Inventor 王育辉

Owner 王育辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com