Running-in device suitable for micro-small ball screw pair and running method thereof

A ball screw pair, micro-miniature technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of screw shaft system temperature rise, large coaxiality error, radial bias load increase, etc., to achieve running High efficiency, simple structure, and reduced deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

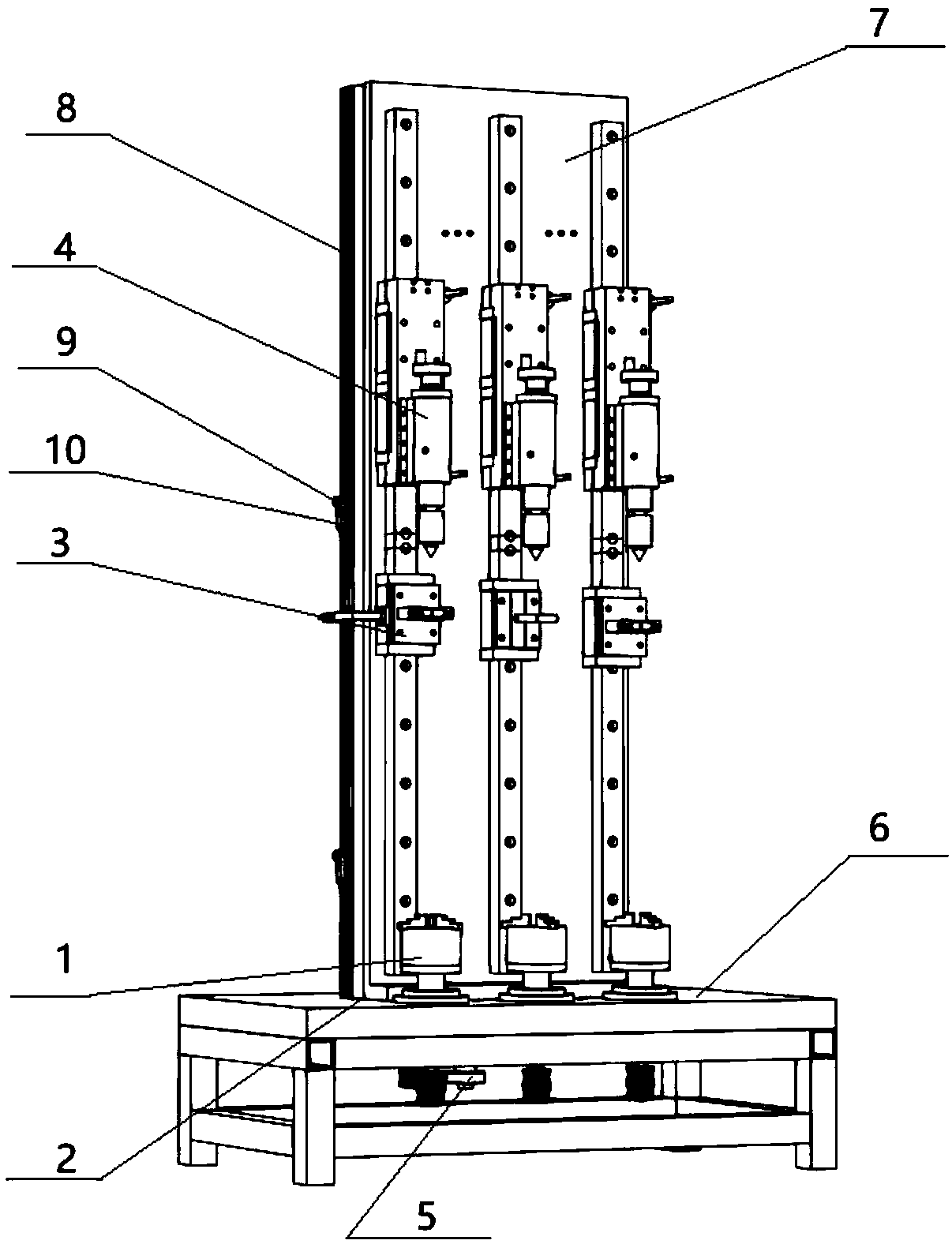

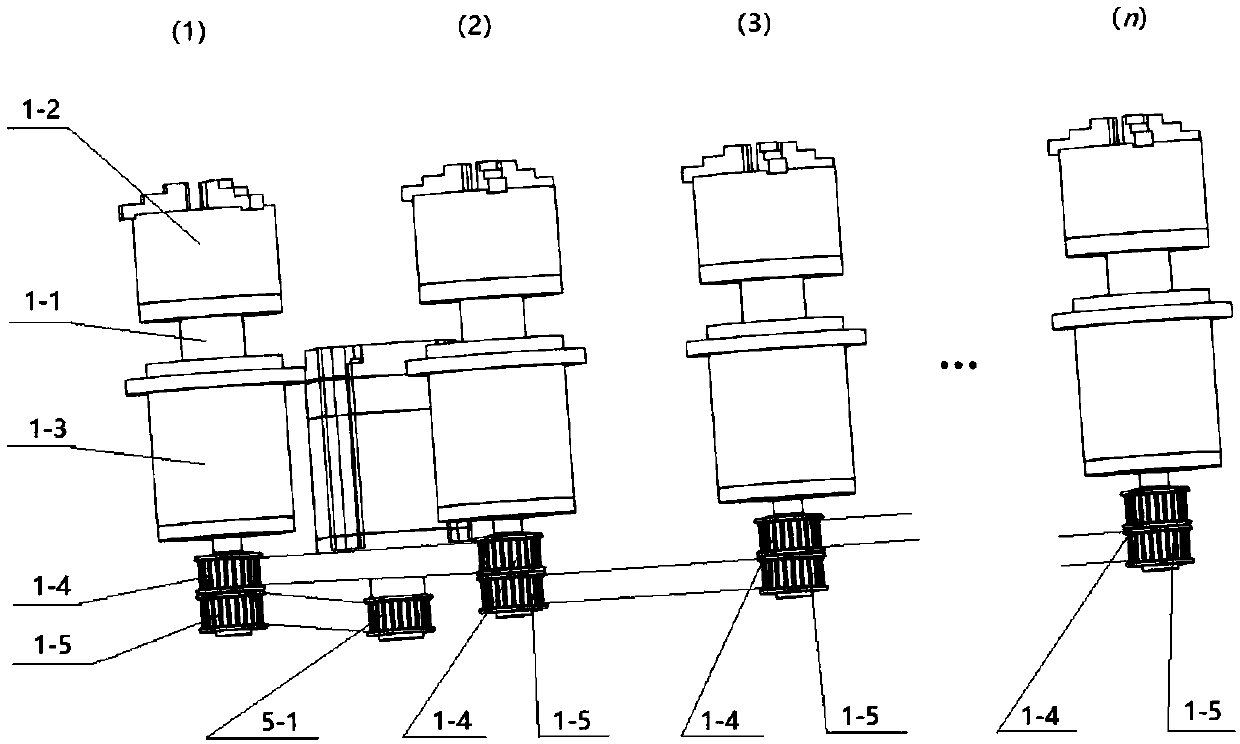

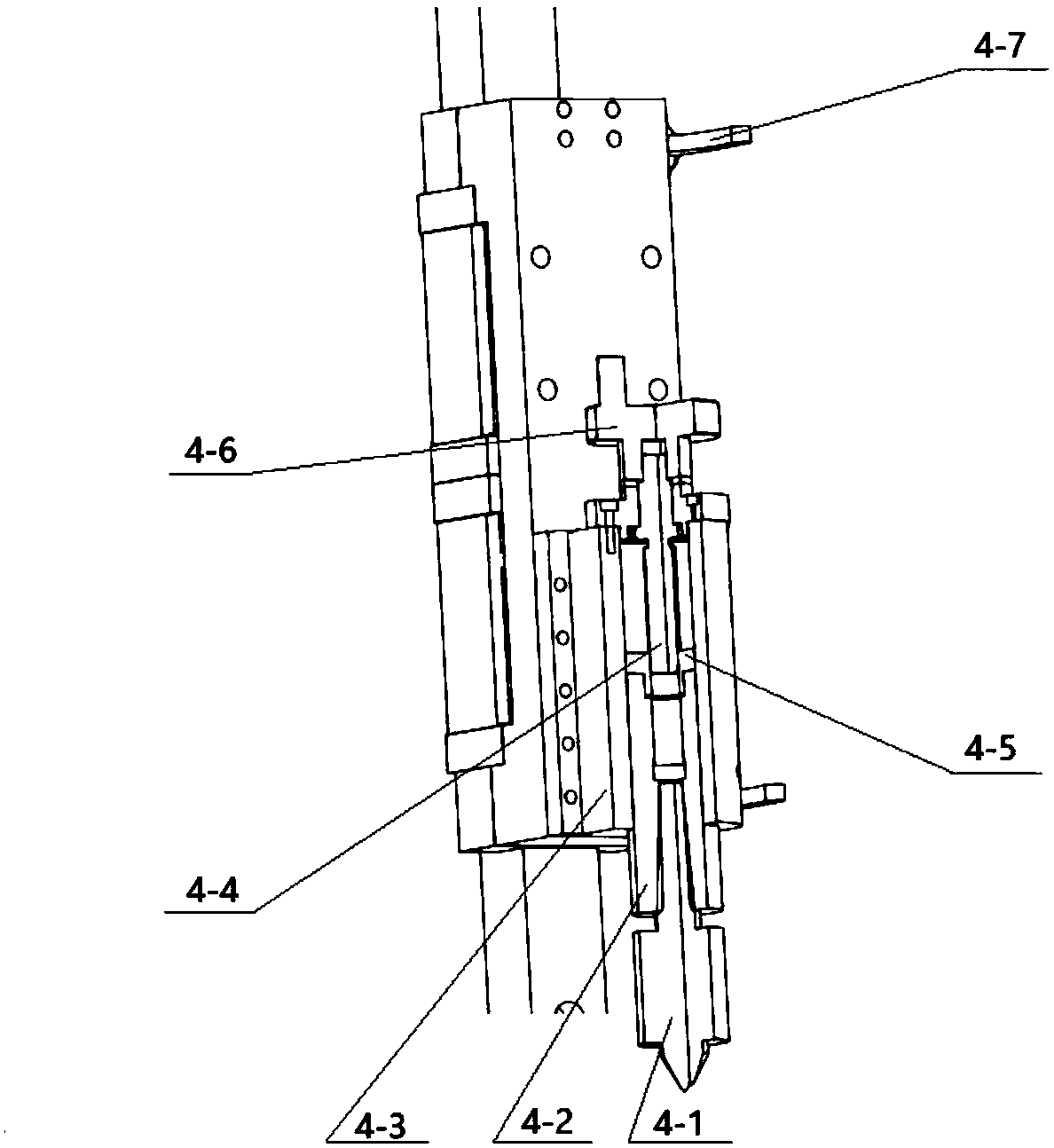

[0038] In this embodiment, n=3, m=2. combine Image 6 , the present invention is suitable for a running-in device for miniature ball screw pairs, including a headstock group, a bed 2, a workbench group, a tailstock group, and a motor 5; the bed 2 includes a base 6 and a panel 7, and the panel 7 Vertically arranged on the upper surface of the base 6; the head frame group includes 3 groups of head frames 1, the workbench group includes 3 groups of workbenches 3, and the tail frame group includes 3 groups of tail frames 4; one side of the panel 7 is provided with 3 A set of guide rails with a first slide block and a second slide block perpendicular to the upper surface of the base 6, each set of guide rails is coaxially arranged with the corresponding tailstock 4 and workbench 3 from the end far away from the base 6, and the tailstock 4. The workbench 3 is set on the first slider and the second slider respectively; the headstock 1 and the tailstock 4 on each set of guide rails, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com