A crack detection system for automobile sheet metal parts based on CNN and LR

A technology for automobile sheet metal parts and crack detection, which is applied in measuring devices, optical testing flaws/defects, image data processing, etc. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as Figure 1-2 As shown, the present invention provides a kind of automobile sheet metal parts crack detection system based on CNN and LR, and concrete detection process is as follows:

[0033] 1) Manually mark positive and negative samples;

[0034] 2) Use the model for training: first use CNN to map the image into a one-dimensional vector of fixed dimensions, use the vector as the feature, and use LR to train the model parameters;

[0035] 3) Predict the new product image to determine whether it is qualified.

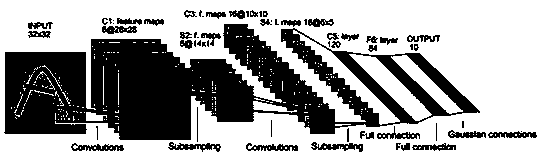

[0036] The process of CNN mapping an input image to a fixed-dimensional vector is as follows:

[0037] The input layer consists of 32×32 perceptual nodes, receiving the original image, and then, the computational pipeline alternates between convolution and subsampling, as follows:

[0038] The first hidden layer is convolved, which consists of 6 feature maps, each feature map consists of 28×28 neurons, and each neuron specifies a 5×5 receptive field;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com