Loading lumped element frequency selection surface

A technology of frequency selective surface and lumped components, which is applied in the direction of electrical components, waveguide devices, circuits, etc., can solve the problems of large electrical size and difficult implementation, achieve simple design process, improve miniaturization index, and broaden the design scope Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

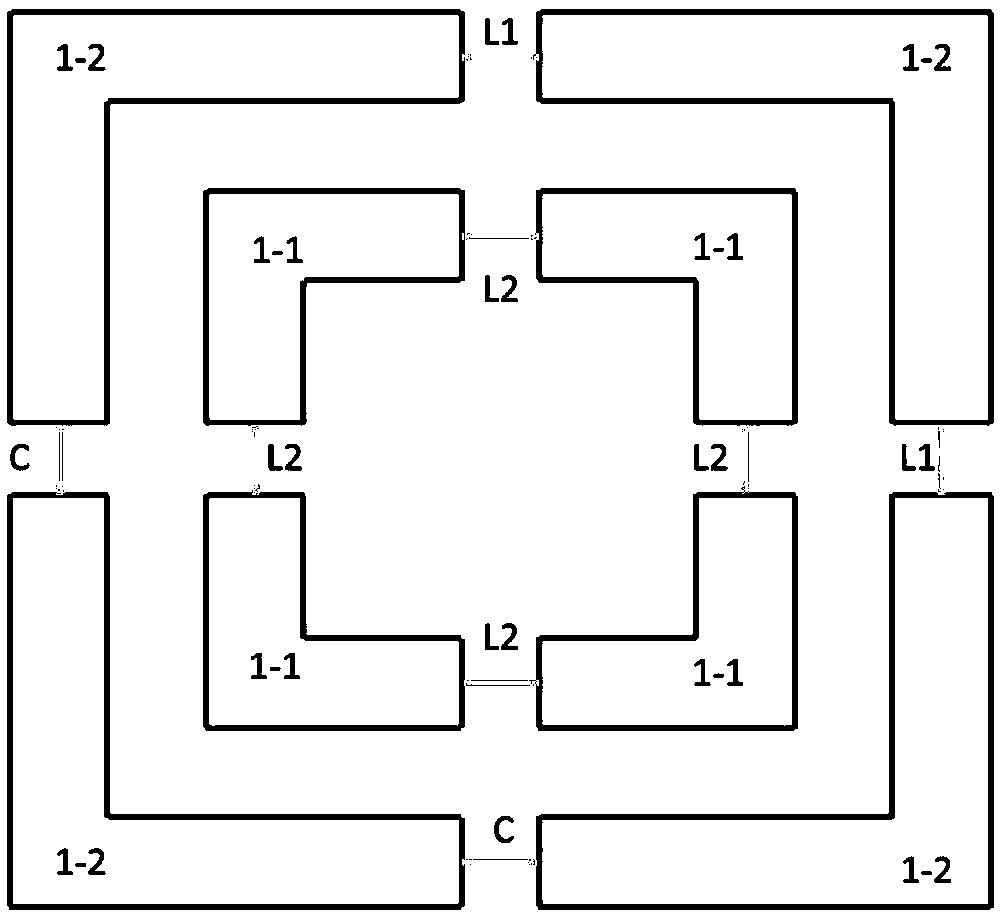

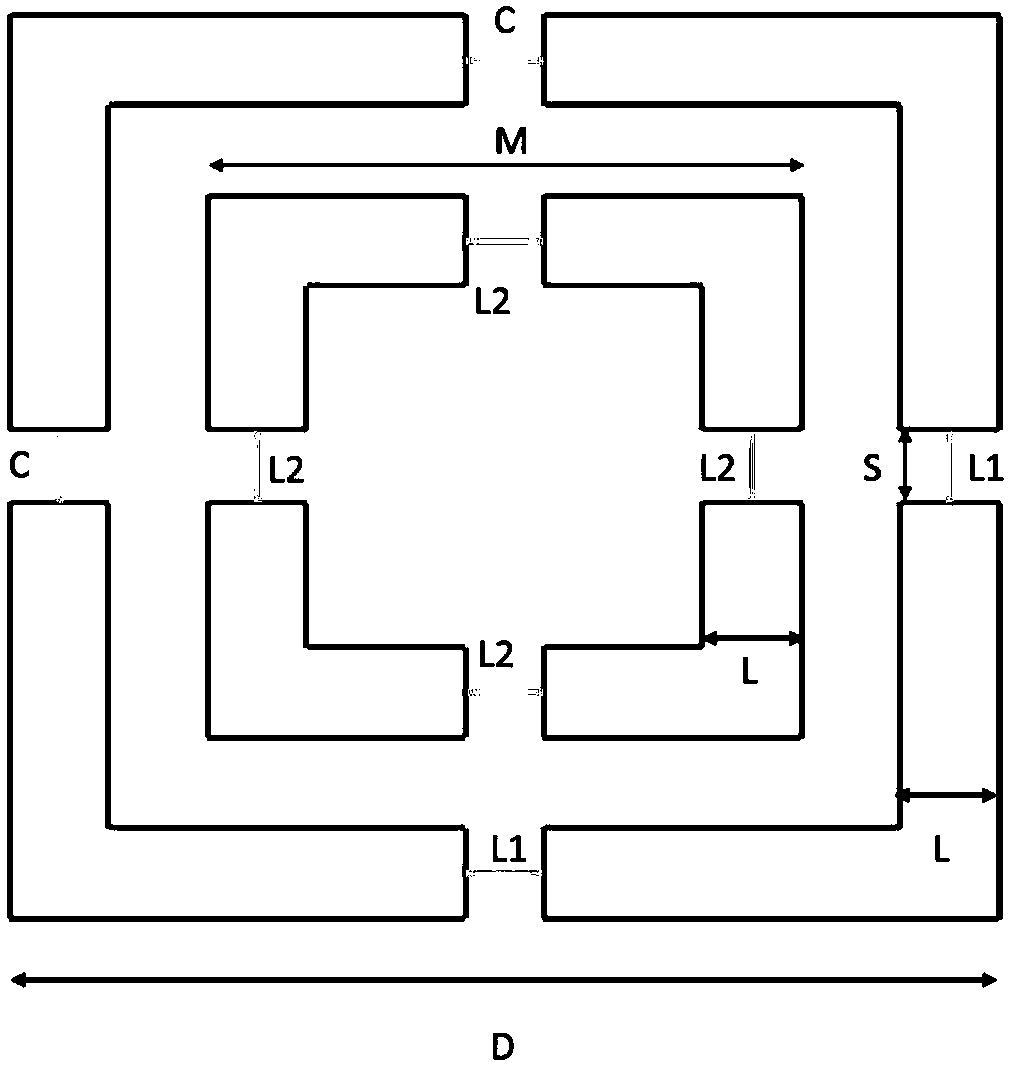

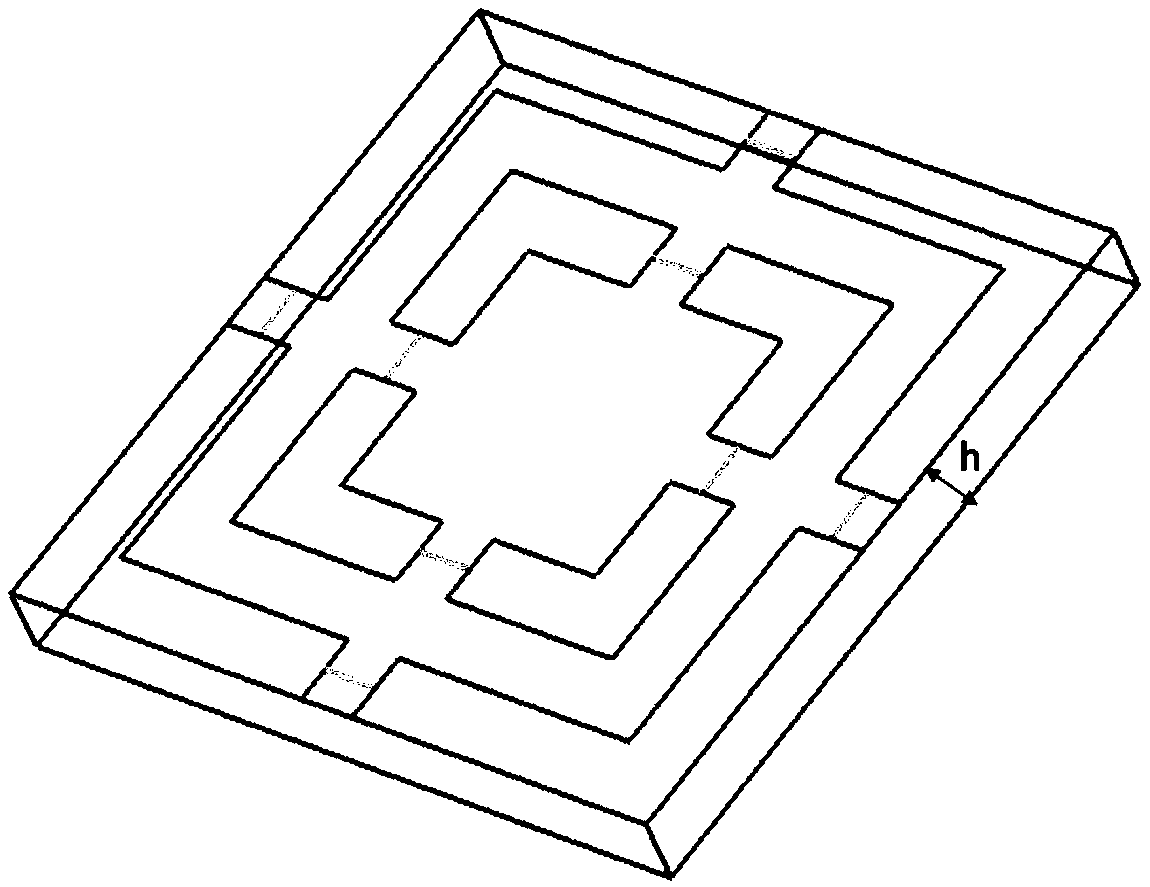

[0028] Such as figure 2 , image 3 As shown, the present invention is mainly composed of a metal structure, a lumped element and a dielectric substrate to realize radiation of two frequencies. The surface satisfies the following properties:

[0029]

[0030]

[0031]

[0032]

[0033]

[0034] In the formula, L 内环 is the equivalent inductance of the inner ring of the structure, L 外环左 is the equivalent inductance on the left side of the outer ring of the structure, L 外环右 is the equivalent inductance on the right side of the outer metal ring of the structure. L 1 , L 2 is the inductance value of lumped inductors L1 and L2, ε eff is the effective permittivity of the dielectric plate. mu 0 is the magnetic permeability in vacuum, ε 0 is the dielectric constant in vacuum, ε r is the dielectric coefficient of the dielectric plate, C 缝隙 is the gap capacitance between the inner and outer rings.

[0035]

[0036]

[0037]

[0038]

[0039] Among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com