Tea leaf fixation machine

A technology of green-fixing machine and tea leaves, which is applied in the field of green-fixing machines, can solve the problems of affecting the effect of green-fixing, uneven heating, uneven heating, etc., and achieve the effect of avoiding uneven heating, avoiding concentrated distribution, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

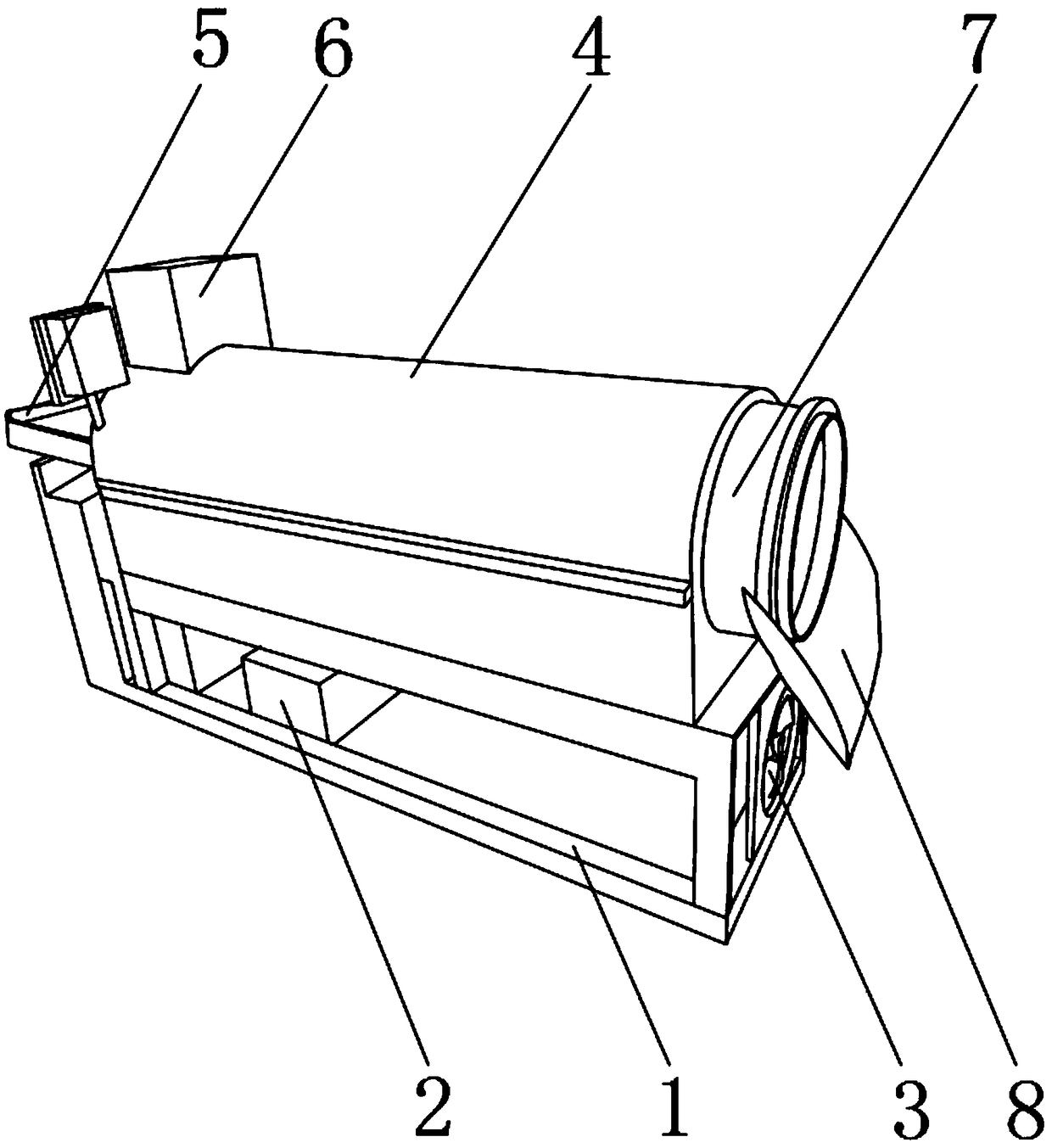

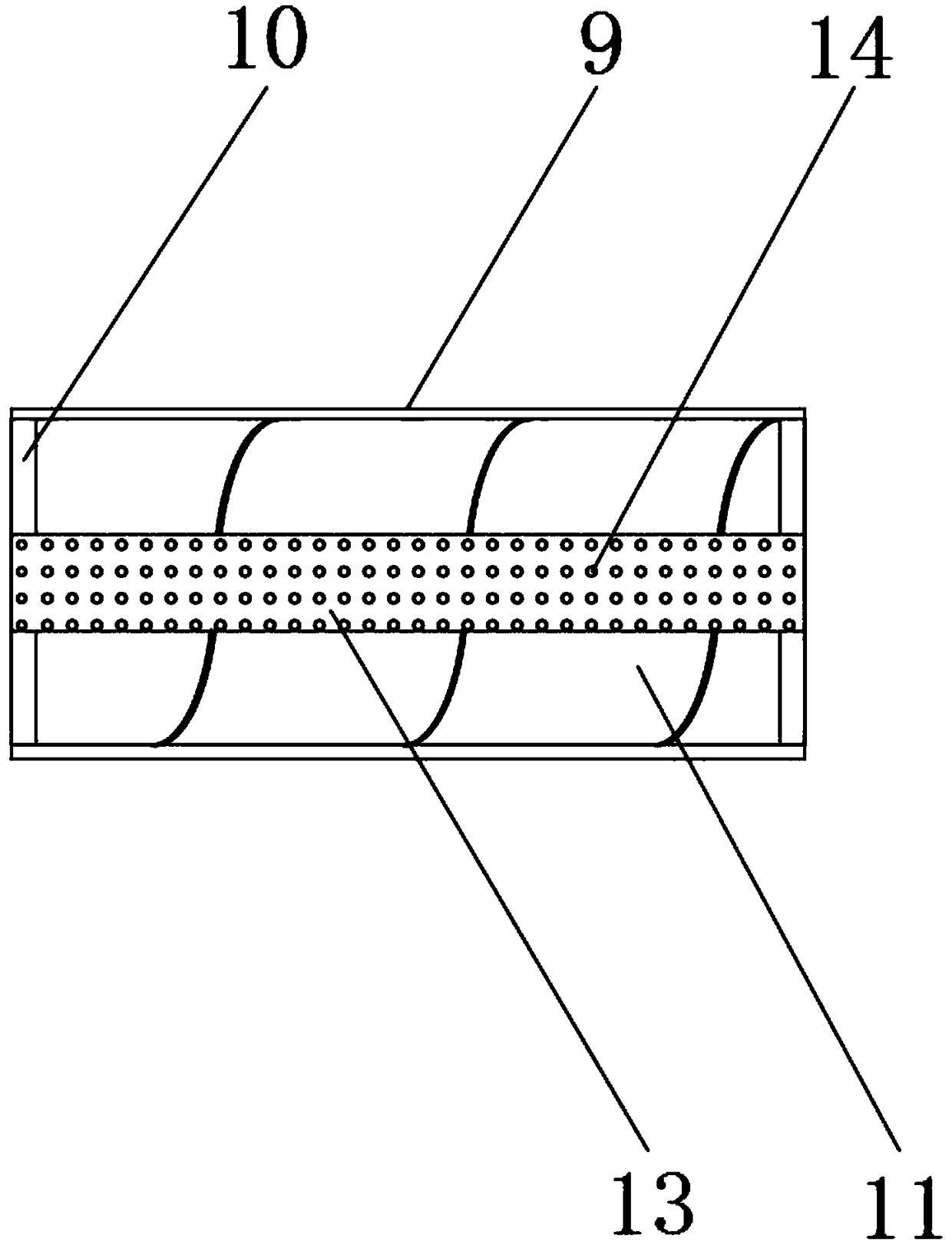

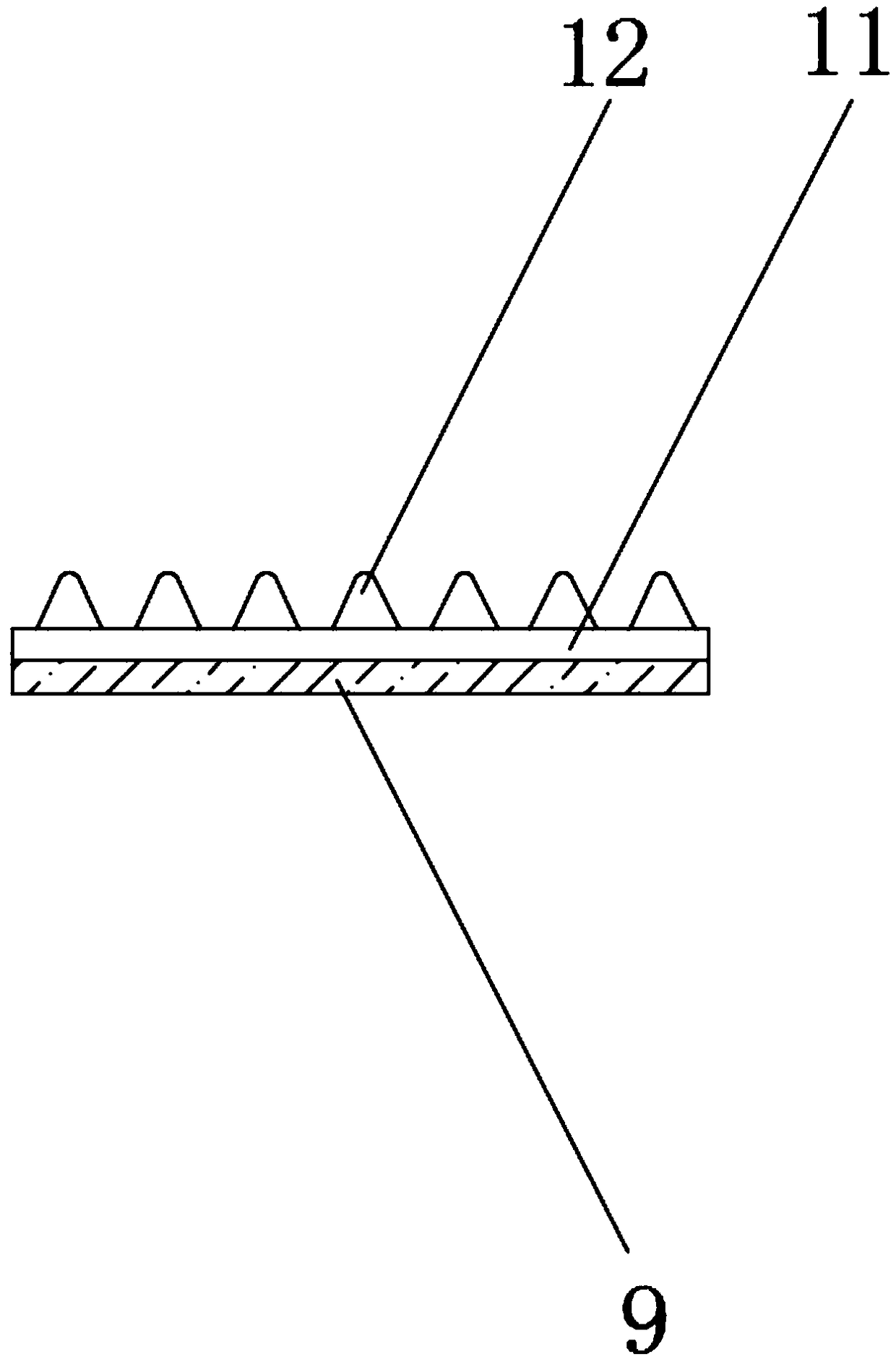

[0025] Such as Figure 1-5 As shown, it includes a bracket 1 and a drum 9, the drum 9 is movably installed inside the bracket 1, the inner surface of the bracket 1 is welded with a heating control box 2, the outer surface of the rear end of the bracket 1 is fixed with a fan 3 by bolts, and the top of the bracket 1 The outer surface is welded with a cylinder 4, and the outer surface of the front end of the cylinder 4 is fixed with a feed hopper 5 by bolts, the outer surface of the cylinder 4 is welded with a controller 6 near the front end, and the center of the rear outer surface of the cylinder 4 The discharge pipe 7 is welded, and the outer surface of the discharge pipe 7 is fixed with a guide plate 8 by bolts near the bottom end, and the inner surface of the drum 9 is fixed with a fixed ring 10 by bolts near the front and rear ends. The inner surface is fixedly equipped with a long charcoal inner shell 11, and the top outer surface of the long charcoal inner shell 11 is fix...

Embodiment 2

[0029] Such as Figure 1-5 As shown, it includes a bracket 1 and a drum 9, the drum 9 is movably installed inside the bracket 1, the inner surface of the bracket 1 is welded with a heating control box 2, the outer surface of the rear end of the bracket 1 is fixed with a fan 3 by bolts, and the top of the bracket 1 The outer surface is welded with a cylinder 4, and the outer surface of the front end of the cylinder 4 is fixed with a feed hopper 5 by bolts, the outer surface of the cylinder 4 is welded with a controller 6 near the front end, and the center of the rear outer surface of the cylinder 4 The discharge pipe 7 is welded, and the outer surface of the discharge pipe 7 is fixed with a guide plate 8 by bolts near the bottom end, and the inner surface of the drum 9 is fixed with a fixed ring 10 by bolts near the front and rear ends. The inner surface is fixedly equipped with a long charcoal inner shell 11, and the top outer surface of the long charcoal inner shell 11 is fix...

Embodiment 3

[0034] Such as Figure 1-5 As shown, it includes a bracket 1 and a drum 9, the drum 9 is movably installed inside the bracket 1, the inner surface of the bracket 1 is welded with a heating control box 2, the outer surface of the rear end of the bracket 1 is fixed with a fan 3 by bolts, and the top of the bracket 1 The outer surface is welded with a cylinder 4, and the outer surface of the front end of the cylinder 4 is fixed with a feed hopper 5 by bolts, the outer surface of the cylinder 4 is welded with a controller 6 near the front end, and the center of the rear outer surface of the cylinder 4 The discharge pipe 7 is welded, and the outer surface of the discharge pipe 7 is fixed with a guide plate 8 by bolts near the bottom end, and the inner surface of the drum 9 is fixed with a fixed ring 10 by bolts near the front and rear ends. The inner surface is fixedly equipped with a long charcoal inner shell 11, and the top outer surface of the long charcoal inner shell 11 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com