Sand making machine capable of regulating grain size of sand

A sand particle size, sand making machine technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problem of uncontrollable sand particle size, etc., to achieve the effect of improving speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

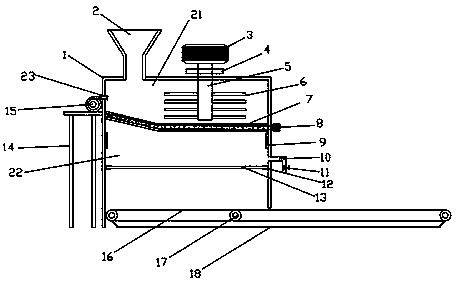

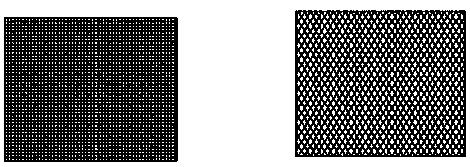

[0021] see Figure 1-3 , a sand making machine with adjustable sand size, including a main body 1, a crushing bin 21 and a screening bin 22, the crushing bin 21 and the screening bin 22 are located inside the main body 1, and the crushing bin 21 is located on the upper part of the screening bin 22, the The top of the main body 1 is provided with a feed port 2, the feed port 2 is a funnel-shaped design, which can make the feed more uniform, and the feed port 2 leads into the crushing bin 21, and the crushing bin 21 is used to crush soft Or medium hard and extremely hard ore materials are broken into sand grains. The inside of the crushing bin 21 is provided with a stirring shaft 5. The upper part of the crushing bin 21 is provided with a motor 3. One end of the motor 3 is provided with a coupling 4. The motor 3. It is connected with the stirring shaft 5 through the coupling 4. The rotating crushing rod 6 is fixed on both sides of the stirring shaft 5. The rotating crushing rod ...

Embodiment 2

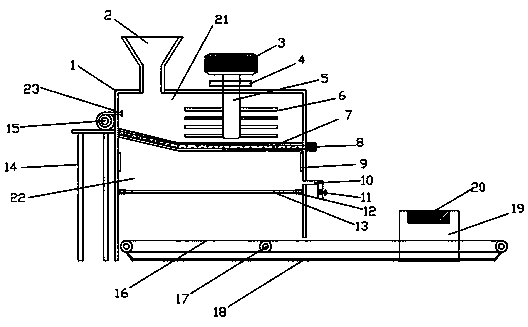

[0023] This embodiment is optimized on the basis of Embodiment 1. The main content of the optimization is: the side of the belt 16 and the fixed base 18 away from the main body 1 is also provided with a drying chamber 19, and the inside of the drying chamber 19 is provided with The dryer 20, the dryer 20 can dry the sand, can be better used.

[0024] The working principle of the present invention is: the raw material enters the crushing bin 21 through the feed port 2 and enters the crushing area, and the motor 3 drives the stirring shaft 5 and the rotating crushing rod 6 to rotate at high speed through the coupling 4, which can crush large-volume raw materials into small sand, the small sand enters the screening bin 22 through the vibrating screen 7, and the screening bin 22 can select sands of different sizes according to the aperture of the screen 13. The aperture of the screen 13 can be replaced, and the sand in the screening bin 22 is from Transfer out in the discharge por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com