Welding device used for automobile bumper

An automobile bumper and welding device technology, applied in the field of automobile spare parts, can solve the problems of welding quality influence, simple structure, bumper adjustment, etc., and achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

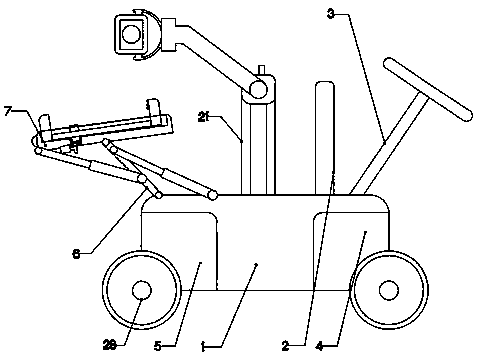

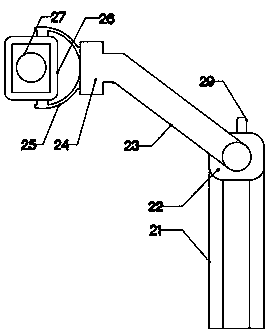

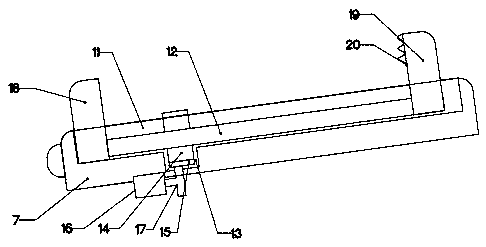

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 shown.

[0021] In this embodiment, the bumper can be effectively displaced through the action of the supporting device, thereby making the working angle more flexible. The bumper can be effectively fixed by the function of the fixing device, and can be adjusted according to the shape of the bumper. Through the function of the auxiliary device, the working intensity of the welding personnel can be reduced to the greatest extent, thereby improving the welding efficiency and welding quality.

[0022] The first step is to place the bumper on the upper surface of the rectangular horizontal plate 7, then the controller 2 controls the relevant electrical appliances to fix the bumper, the controller 2 controls the rotating motor 16 to rotate, and the rotating end of the rotating motor 16 directly drives The second gear 17 rotates, and the rotation of the second gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com