Surfactant for oil displacement, synthetic method and application of surfactant in oil displacement system

A surfactant and synthesis method technology, applied in chemical instruments and methods, preparation of organic compounds, mining fluids, etc., can solve the problems of low micelle concentration, temperature resistance, low cloud point, low solubilization ability, etc., to achieve High micelle concentration, high conversion rate, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

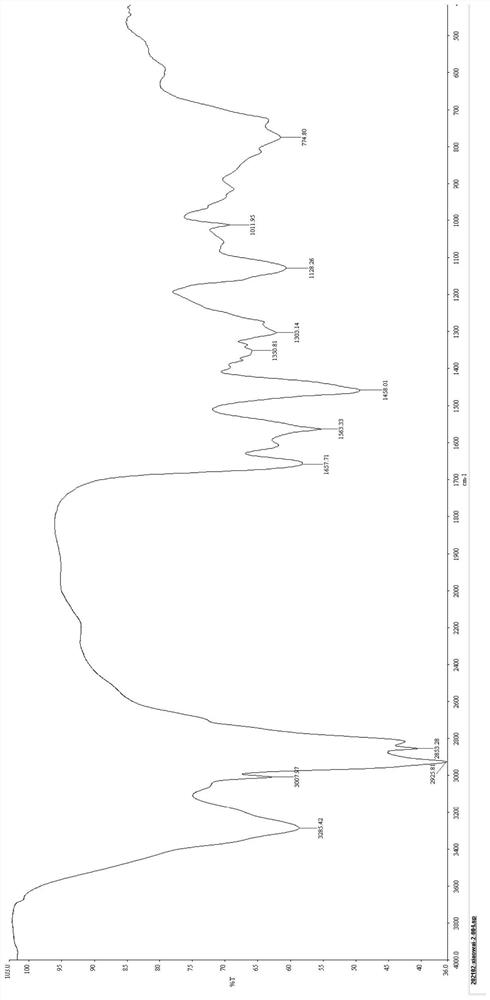

[0061] The synthetic method, performance detection and oil displacement performance test of the sodium oleic acid polyvinyl polyamide polyoxypropylene ether carboxylate non-anion mixed surfactant described in this embodiment are as follows:

[0062] 1. Synthesis method

[0063] Use oleic acid and polyvinylpolyamine acylation reaction to synthesize acylate intermediate, the reaction formula is:

[0064]

[0065] In the formula, n is an integer between 5-7;

[0066] (1) In a 1000ml four-necked reaction flask equipped with a condenser, a water separator, a stirrer and a thermometer, add 169g of oleic acid, 263g of polyvinylpolyamine, 160g of xylene with water agent, and after sealing, heat up and carry out acylation Reaction, after the temperature is higher than 150 °C, the water produced by the acylation reaction of xylene with water agent is azeotropically distilled, and after condensation, the water is separated into the measuring tube, and the xylene is distilled back int...

Embodiment 2

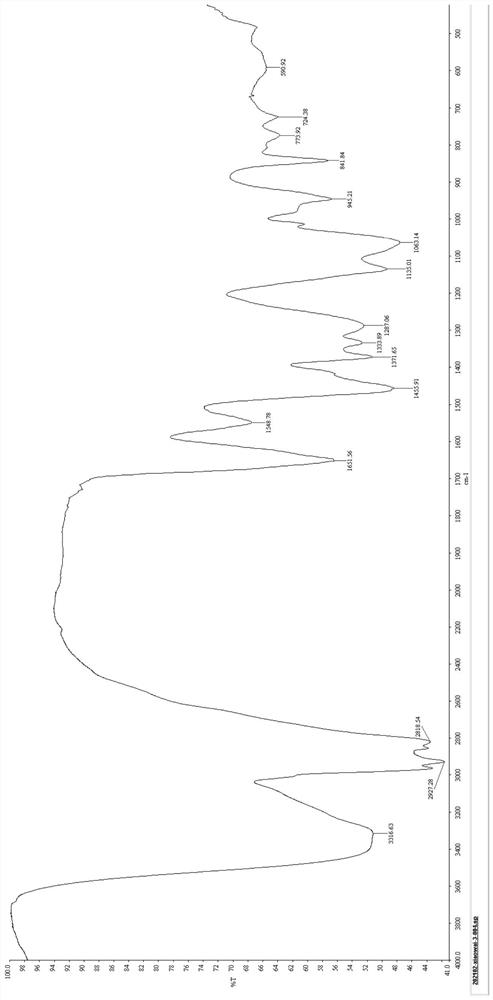

[0089] The synthetic method, performance detection and oil displacement performance test of the sodium naphthenic acid polyvinyl polyamide polyoxypropylene ether carboxylate non-anion mixed surfactant described in this embodiment are as follows:

[0090] 1. Synthesis method:

[0091] 1. The acylation reaction of naphthenic acid and polyvinylpolyamine to synthesize acylate intermediate, the reaction formula is:

[0092]

[0093] In the formula, R 0 for CH 3 base or C 2 H 5 ; n is an integer between 1-5; m is an integer between 1-3; k is an integer between 5-7;

[0094] In a 1000ml four-necked reaction flask equipped with a condenser, a water separator, a stirring paddle and a thermometer, add 175g of naphthenic acid with a crude acid value of 160mgKOH / g, 219.5g of polyethylene polyamine, and 160g of xylene, and stir slowly. The acylation reaction is carried out by heating up, when T 反 After >150°C, the water produced in the reaction is carried out by azeotropic distill...

Embodiment 3

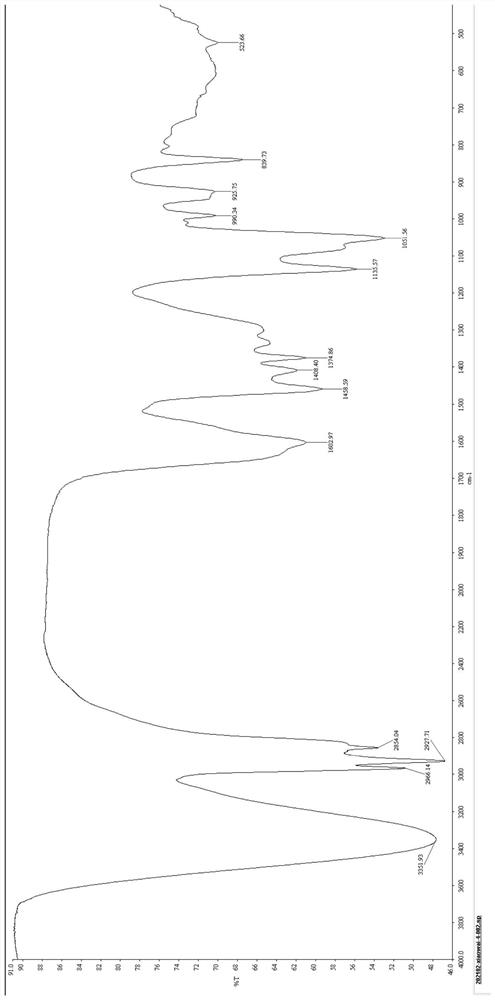

[0117] The synthesis method, performance detection and oil displacement performance experiment of the palmitic acid polyvinyl polyamide polyoxypropylene ether carboxylate sodium non-anion mixed surfactant of the present application are as follows.

[0118] 1. Synthesis method

[0119] 1. Acylation reaction of palmitic acid (carbon hexadecanoic acid) and polyvinylpolyamine to synthesize an acylate intermediate. The reaction formula is:

[0120]

[0121] In the formula, n is an integer between 5-7;

[0122] (1) In a 1000ml four-necked flask equipped with a condenser, a water separator, a stirrer and a thermometer, add 128.0g of palmitic acid, and control the temperature to be 60°C. After the material is fully dissolved, add 219.5g of polyethylene polyamine, and two Toluene 140g, fully stirred and homogenized after the instrument is sealed, and heated to 150 °C to enter the acylation reaction; the water generated in the reaction is taken out by the azeotropic distillation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com