A Practical Test Device for Bearing Capacity of Shear Parts

A test device and the technology of shearing parts, which are applied in the field of practical shearing part bearing capacity test devices, can solve the problems of lack of reference objects for measuring deformation and poor experimental accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

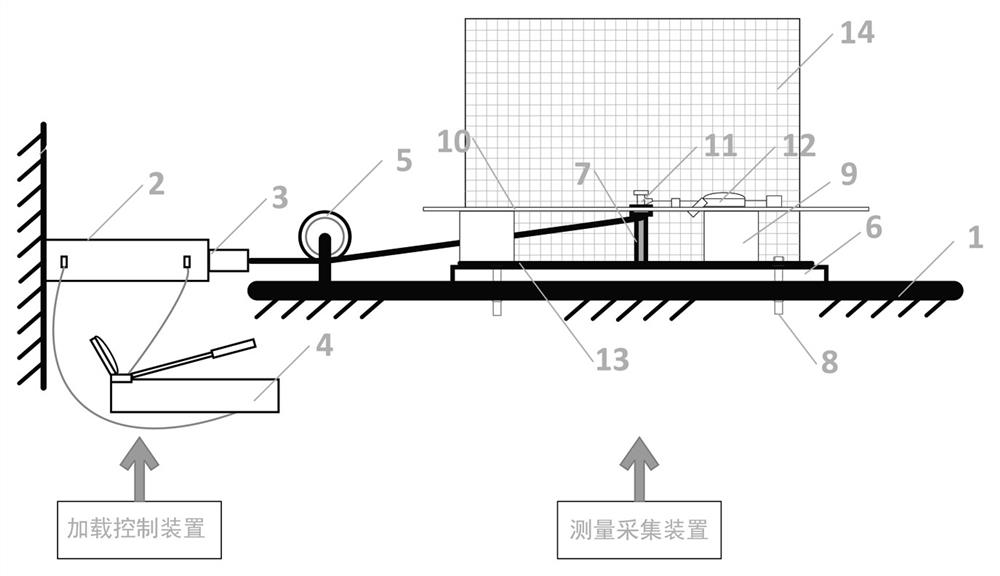

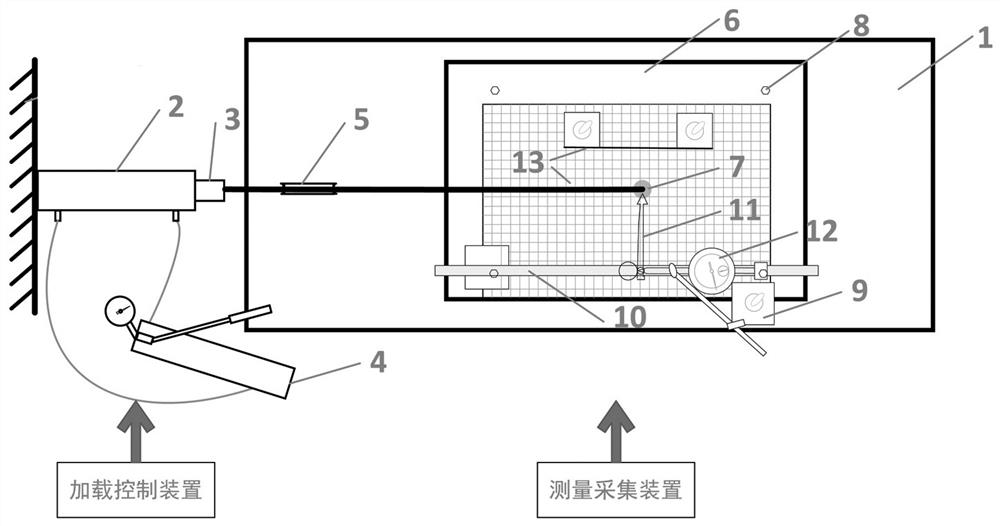

[0020] Embodiment 1: This embodiment aims to provide a practical test device for the bearing capacity of shear members, and provides an effective test loading measurement device for studying the mechanical properties of individual shear members. A single load can be applied to judge the bending deformation of the intermediate shear parts, and there is no reference object for measuring the deformation during the test process, and only the naked eye observation of the test personnel results in poor test accuracy. This embodiment provides an operation Simple, high precision, and two reference objects are set in the horizontal and vertical directions to mark its effective displacement.

[0021] Specifically, such as Figure 1-2 As shown, a practical test device for the bearing capacity of a shear member includes a loading control device and a measurement acquisition device; the loading control device is used to apply a loading force to the shear member, and the measurement acquisi...

Embodiment 2

[0034] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further limits the way of setting collection points.

[0035] The collection point is provided with a mounting hole, a laser emitting head is fixed in the mounting hole, and a detecting head is arranged on the back of the vertical coordinate paper, and the detecting head can collect the path and displacement of the laser emitting head.

[0036] In this embodiment, a laser emitting head is set at the collection point. The laser emitting head is small in size and light in weight and has little impact on the test of the shearing capacity. At the same time, it can emit laser light on the vertical coordinate paper, and the laser is shot on the coordinate paper. It is convenient for the test personnel to make dots on the coordinate paper, and at the same time, the detection head can record the path walking image of the laser displacement, and extract its walking path on ...

Embodiment 3

[0038] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further explains the structure of the pointer.

[0039] The pointer points to the collection point in the initial state. With the displacement of the collection point, the pointer can be driven to slide in the guide rail. In order to facilitate the identification of the location of the collection point, a reference rod is vertically set at the end of the pointer. When the pointer is moved, the reference rod and The corresponding position of the collection points can indicate that the pointer has moved in place, and the precise displacement can be obtained through the reading of the dial indicator.

[0040] In the present invention, the piston rod of the jack is connected to the fixed pulley through a steel strand, and the other end is connected to the outer end of the shear member. When the piston rod moves in the reverse direction, it drives the shearing parts, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com