Cutting device for hard rubber plate

A cutting device and hard rubber technology, applied in the field of rubber processing, can solve the problems of unguaranteed cutting flatness, reduced service life, increased worker burden, etc., and achieve the effects of reducing worker burden, facilitating operation, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

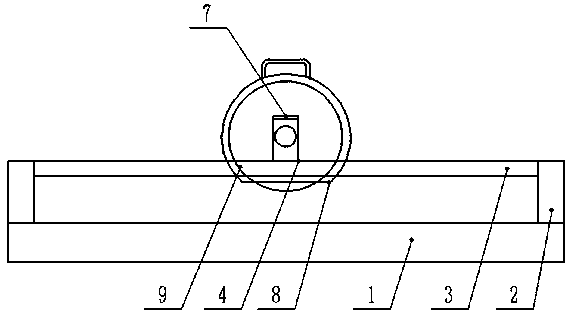

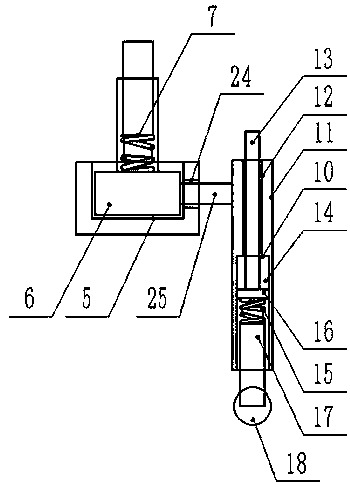

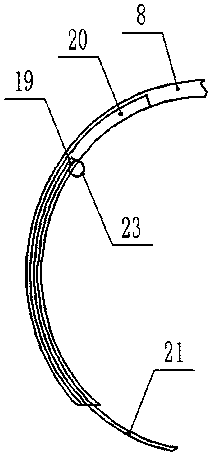

[0016] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 Now, a cutting device for hard rubber sheets provided by the present invention is described, which includes a rectangular workbench 1, and a group of vertical frames 2 are respectively arranged on the upper end of the rectangular workbench 1 and on both sides along its length direction. A horizontal frame 3 is respectively fixed between the top of the vertical frame 2 and along the longitudinal direction of the rectangular workbench 1, and a mobile cutting mechanism 4 is arranged between the horizontal frame 3, and the mobile cutting mechanism 4 is formed by the horizontal frame 3. Between the chute 5 provided in the middle part of the upper end of the frame 3 and along its length direction, the sliding seat 6 respectively provided in the chute 5, the vertical telescopic frame 7 fixedly provided on the upper end of the sliding seat 6, and the horizontal frame 3 The provided hollow arc-shaped housing 8 and ...

Embodiment 2

[0017] Example 2: see figure 1 , figure 2 Now, a cutting device for hard rubber sheets provided by the present invention will be described. The vertical frame 2 is arranged in parallel at intervals along the width direction of the rectangular worktable 1, and is located on both sides of the rectangular workbench 1 in the longitudinal direction. The vertical frame 2 is arranged correspondingly, and the vertical telescopic frame 7 includes a hollow column fixedly arranged at the bottom end and the upper end of the slide seat 6, a support frame movably inserted into the hollow column, and the inner bottom end of the hollow column and the bottom end of the support frame. A second return spring is provided between them, and the top end of the support frame is fixedly connected to the outside of the hollow arc-shaped housing 8 .

Embodiment 3

[0018] Embodiment 3: see figure 1 Now, a cutting device for hard rubber sheet provided by the present invention is described. The bottom end of the hollow arc-shaped shell 8 has a cutting opening, and the top end of the hollow arc-shaped shell 8 is provided with a handle frame. The cutting assembly 9 includes a rotating shaft, a blade and a driving motor, the blade protrudes through the cutting opening, and the vertical cross section of the hollow arc-shaped housing 8 is arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com