A multi-material molding device with a powder control baffle and its 3D printing method

A molding device and multi-material technology, which is applied in the field of 3D printing, can solve the problems of powder mixing of multi-material molding parts, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

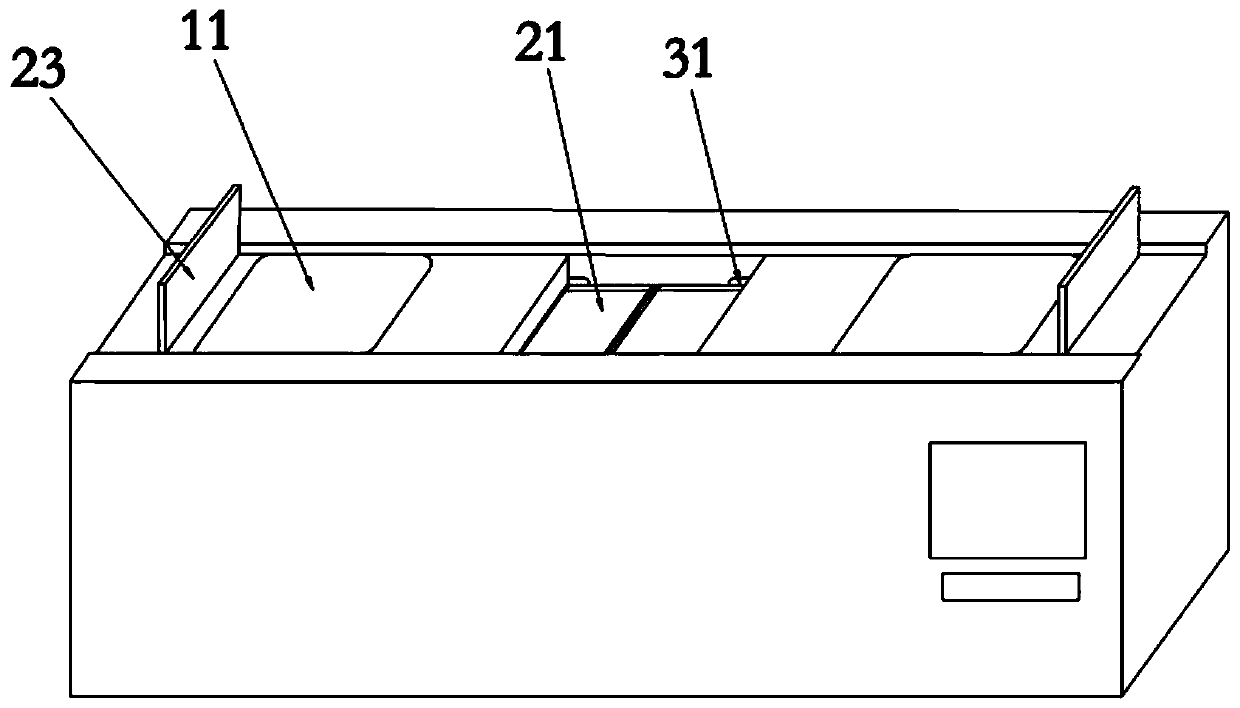

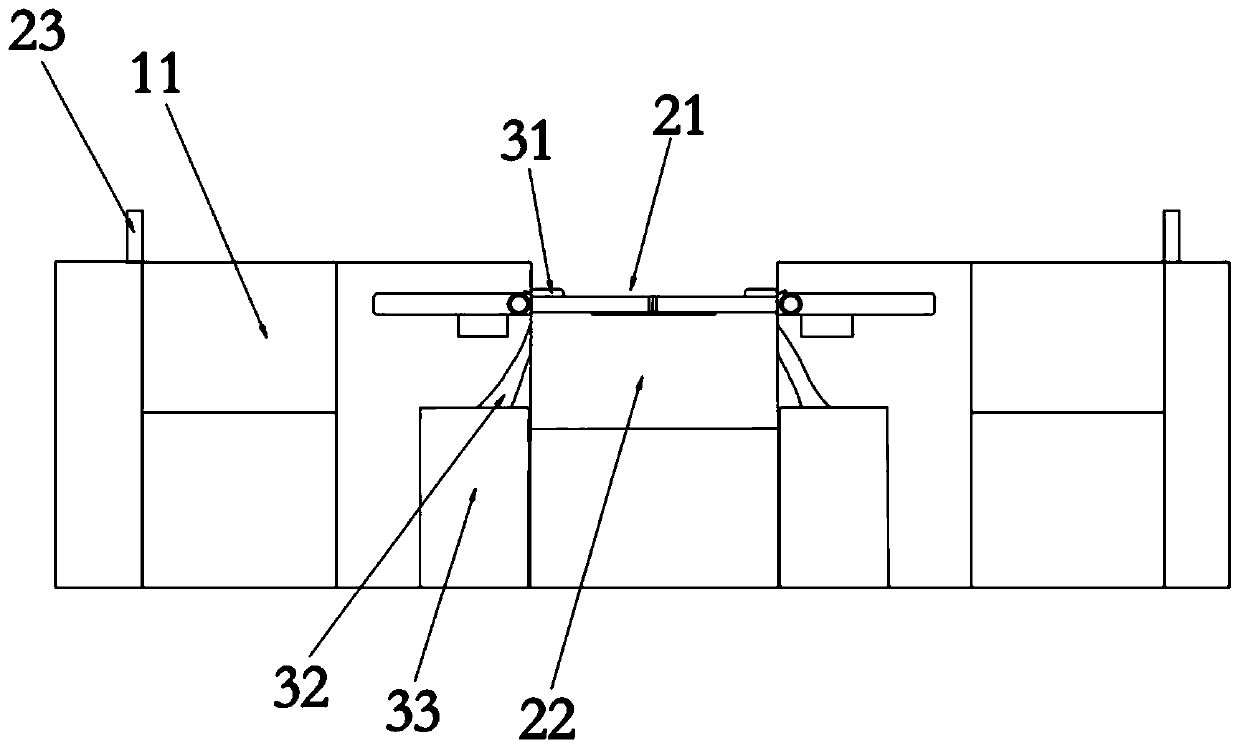

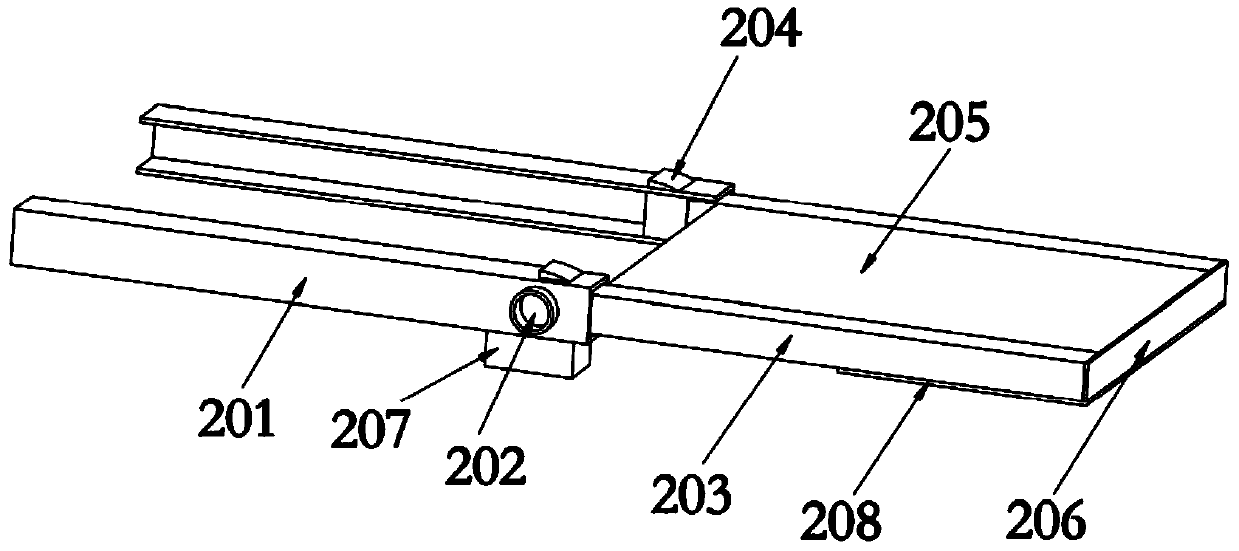

[0032] Such as Figure 1 to Figure 7As shown, the multi-material molding device provided in this embodiment includes a powder supply mechanism, a powder spreading mechanism and a powder collecting mechanism. The powder materials required for parts (not shown in the figure) include multiple powder cylinders 11 and the pistons at the bottom. The powder cylinders 11 are respectively arranged on both sides of the powder spreading mechanism, and the lifting height is controlled by the pistons at the bottom. The powder spreading mechanism comprises telescopic powder control baffle plate 21, forming cavity 22, whitewashing brush 23 and piston (not shown in the figure), and forming cavity is located at the inside of powder spreading mechanism, and telescopic powder control baffle plate 21 has two One, is arranged on the top of molding cavity 22 in the left and right split structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com