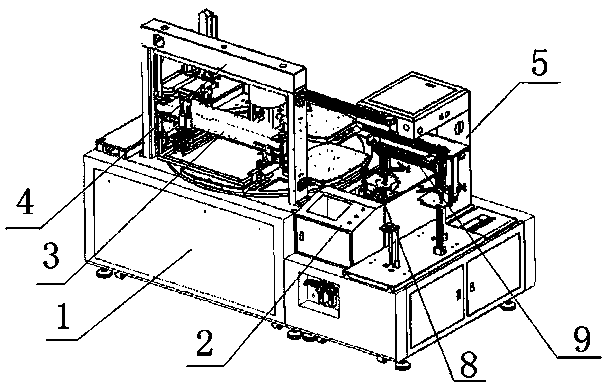

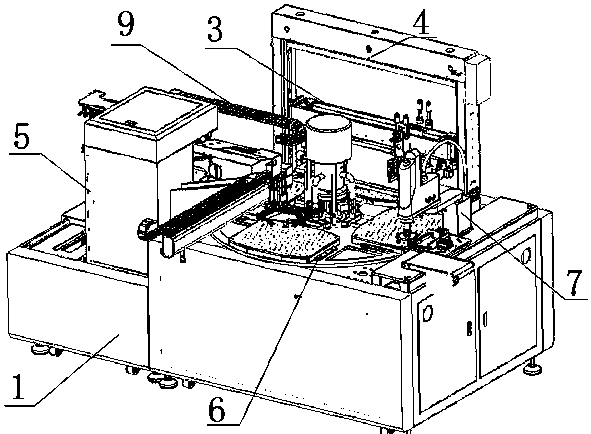

Multi-station rotary-table screen printing machine

A multi-station, screen printing machine technology, applied to rotary printing machines, screen printing machines, printing machines, etc., can solve the problems of poor position accuracy, increased workload, low efficiency, etc., to improve screen printing efficiency and work efficiency , Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

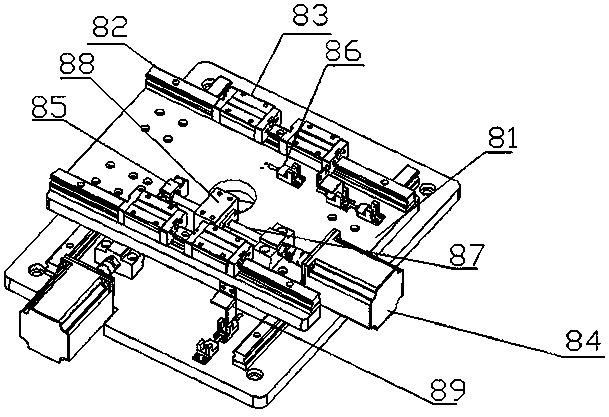

[0054] In this embodiment, the substrate 839 is a wrapping paper, and the screen printing device screen printing is glue. In this embodiment, all controls are completed by an intelligent control platform.

[0055] When working, the three-axis adjustment bearing table 8 can adjust the X-axis, Y-axis coordinates and the angle of the R-axis of the wrapping paper in the plane, and then put the wrapping paper X-axis, Y-axis and R-axis of the bearing table again The coordinates of, do not need to be adjusted again. You only need to adjust the situation that the wrapping paper is not completely placed on the supporting table 838. When the wrapping paper is not completely placed on the supporting table 838, the expansion and contraction of the cylinder 8351 drives the vertical plate 835 to move. 835 pushes the edge of the wrapping paper to move so that the wrapping paper is completely placed in the supporting table 838. The adjusted position of the wrapping paper is grabbed by the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com