Electric vehicle axle disc brake hub structure

A technology for electric vehicles and axles, applied in the directions of wheels, braking components, axles, etc., can solve the problems of stress concentration of axle shaft materials, traffic accidents, broken half axles, etc., to improve fatigue resistance, safe and reliable use, Avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and specific embodiments:

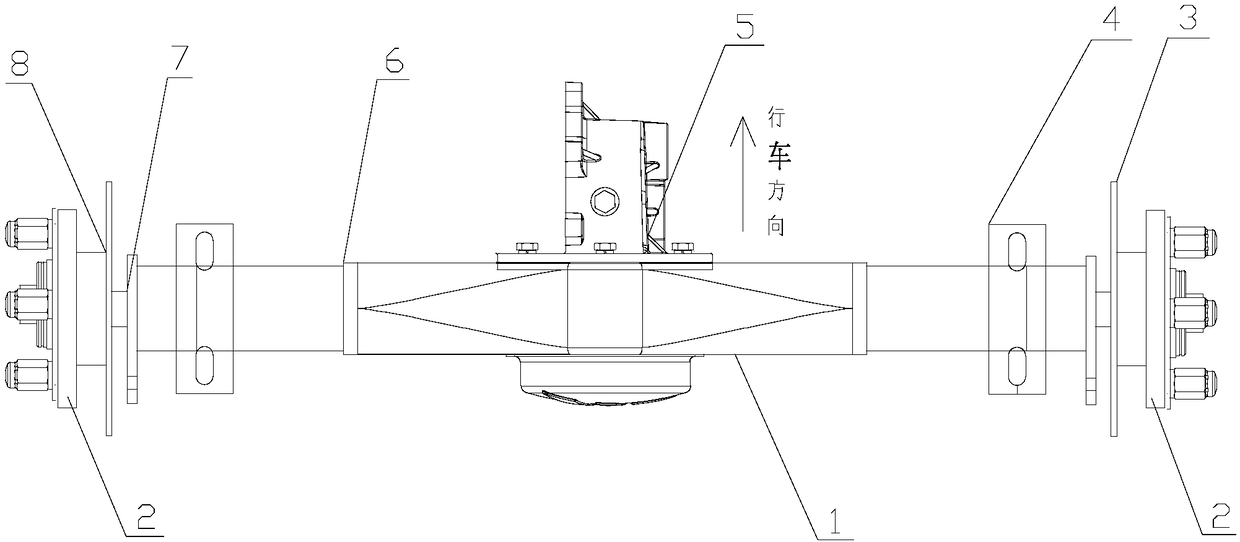

[0013] Such as figure 1 As shown, an electric vehicle axle disc brake hub structure for a vehicle includes an axle main shaft 1, a hub 2 and a disc brake device. A differential box 5 is provided in the middle of the axle main shaft 1, and both ends of the axle main shaft 1 are respectively A hub 2 is provided. The inner side of the hub 2 at both ends of the axle shaft 1 is respectively provided with a disc brake assembly flange 3, the inner side of the disc brake assembly flange 3 is respectively provided with a bearing sleeve 7, and the inner side of the bearing sleeve 7 is respectively provided with a skateboard bracket 4 .

[0014] In this embodiment, a bridge tube 6 is provided between the axle shaft 1 and the hubs 2 on both sides thereof, the bearing sleeve 7 is provided at the end of the bridge tube 6, and the sliding plate bracket 4 is provided on the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com