Low-noise and high-low-pressure pipeline assembly and method for manufacturing the same

A high-low-pressure, high-pressure pipe technology, applied in heating/cooling equipment, air handling equipment, transportation and packaging, etc., can solve the problems of expansion valve and compressor efficiency reduction, affecting air conditioning refrigeration efficiency and compressor power consumption, etc., to achieve Reduce heat transfer, strong practicability, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

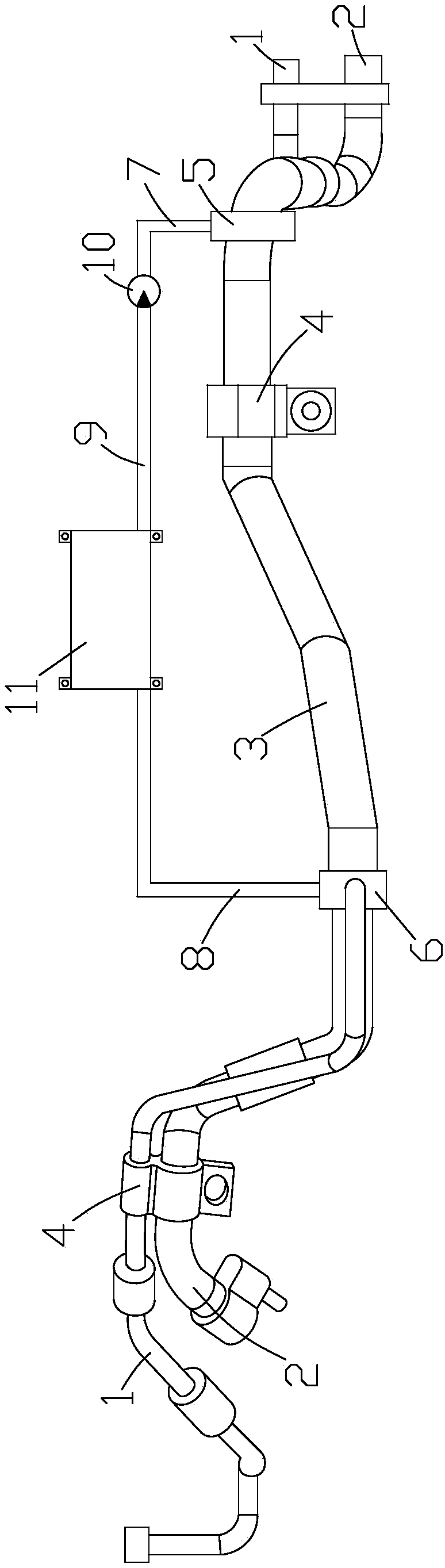

[0041] Such as Figure 1 to Figure 2 As shown, it is a low-noise high-low pressure pipeline assembly of the present invention, which includes a high-pressure pipe 1 and a low-pressure pipe 2, and also includes a heat preservation pipe 3 and a cooling device. The two ends of the heat preservation pipe 3 are respectively provided with a first positioning block 5 and a The second positioning block 6, the high-pressure pipe 1 and the low-pressure pipe 2 run through the first positioning block 5, the thermal insulation pipe 3 and the second positioning block 6, and the high-pressure pipe 1, the low-pressure pipe 2 and the thermal insulation pipe 3 are all provided with a positioning clamp 4, and the positioning Clip 4 is convenient for the connection of high-pressure pipe 1, low-pressure pipe 2 and auto parts.

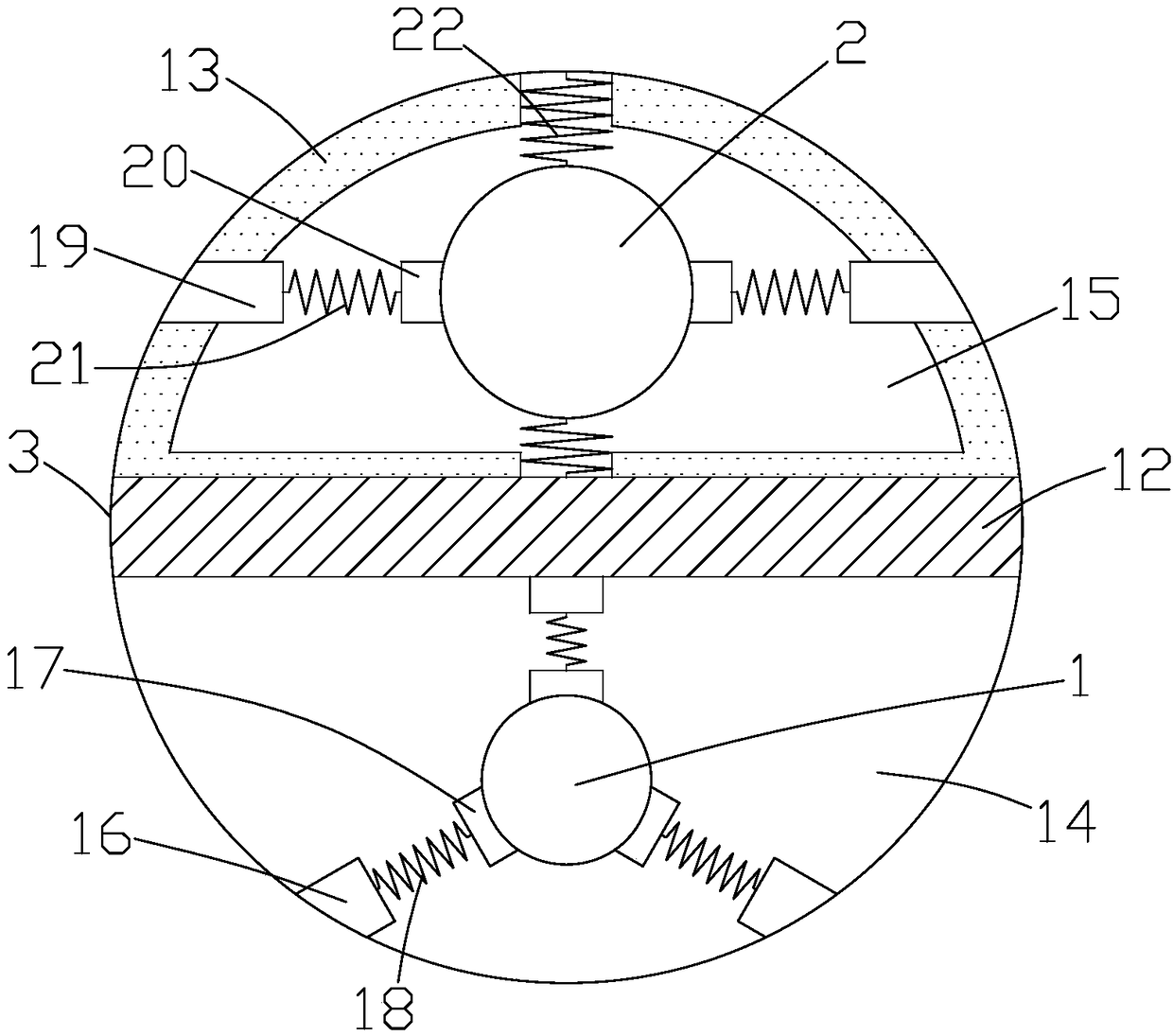

[0042] The heat insulation pipe 3 is provided with a heat insulation board 12, and the heat insulation pipe 3 is divided into a first cavity 14 and a second cavity 15 by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com