A kind of hard ceramic coating with antibacterial and corrosion resistance and preparation method thereof

A hard ceramic, corrosion-resistant technology, applied in coatings, metal material coating processes, vacuum evaporation plating, etc., can solve the problems of small protection range and no corrosion resistance of the protective layer, and achieve excellent mechanical behavior and high performance. The effect of improving hardness and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Clean the polished 304 stainless steel substrate, put in successively a concentration of 60% decontamination powder aqueous solution, saturated Na 2 CO 3 Water solution, acetone, absolute ethanol, and deionized water were ultrasonically cleaned for 15 minutes, and then dried with high-purity nitrogen gas with a purity of 99.99%. Then, the substrate was placed on the sample stage in the vacuum chamber. -3 After Pa, inject argon gas and maintain the pressure at 0.5 Pa, then turn on the power supply and apply a negative bias voltage to the substrate at the same time, and use the plasma glow generated by argon to etch and clean it for 15 minutes;

[0070] (2) Zr 58 Cu 30 al 12 The target is connected to the DC power supply, the Cu target is connected to the RF power supply, and the purity of the two targets is greater than 99.9%;

[0071] (3) Put the cleaned substrate into the vacuum chamber, when the vacuum degree of the chamber is ≤5×10 -5 Pa, pass into Ar and N ...

Embodiment 2

[0078] Prepare hard ceramic coating according to the method described in Example 1;

[0079] Wherein, the specific parameters in step (3) are: Cu target power density: 4.15W / cm 2 ; Zr 58 Cu 30 al 12 Target power density: 4.15W / cm 2 ; The flow ratio of nitrogen to argon is N 2 : Ar=0.18; substrate bias: -8V; heating temperature: 200°C; coating deposition rate: 25nm / min.

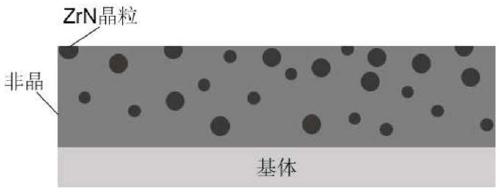

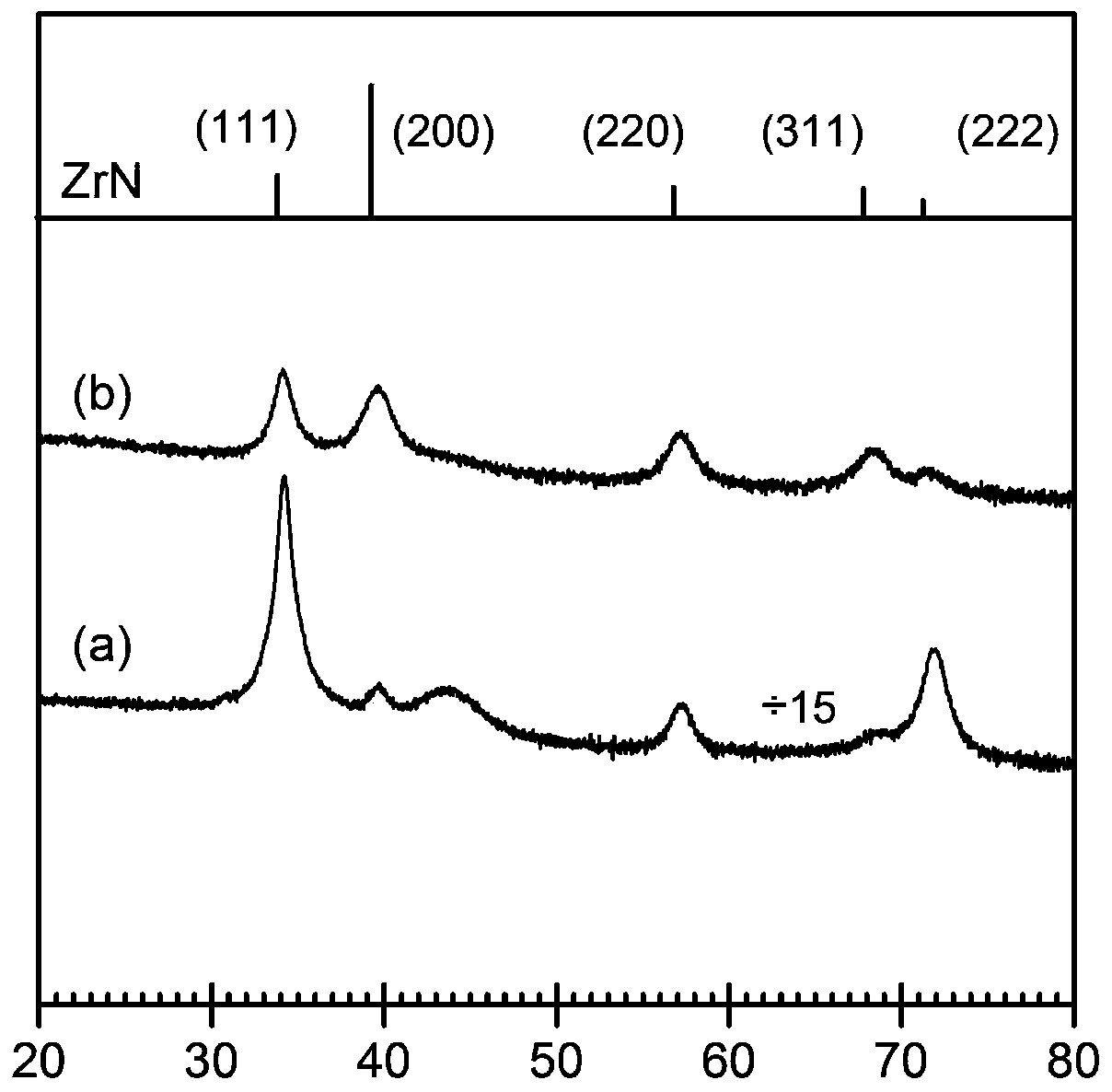

[0080] Structural characterization of the obtained coating: it is found that the composition of the coating obtained in Example 2 is Zr 43.1 Cu 18.8 al 5.2 N 32.9 , showing as figure 1 and figure 2 (b) shows a two-phase composite structure of ZrN crystal grains surrounded by amorphous, wherein the ZrN grain size is 6-15 nm, and the amorphous phase thickness of two adjacent ZrN grains is 10-25 nm.

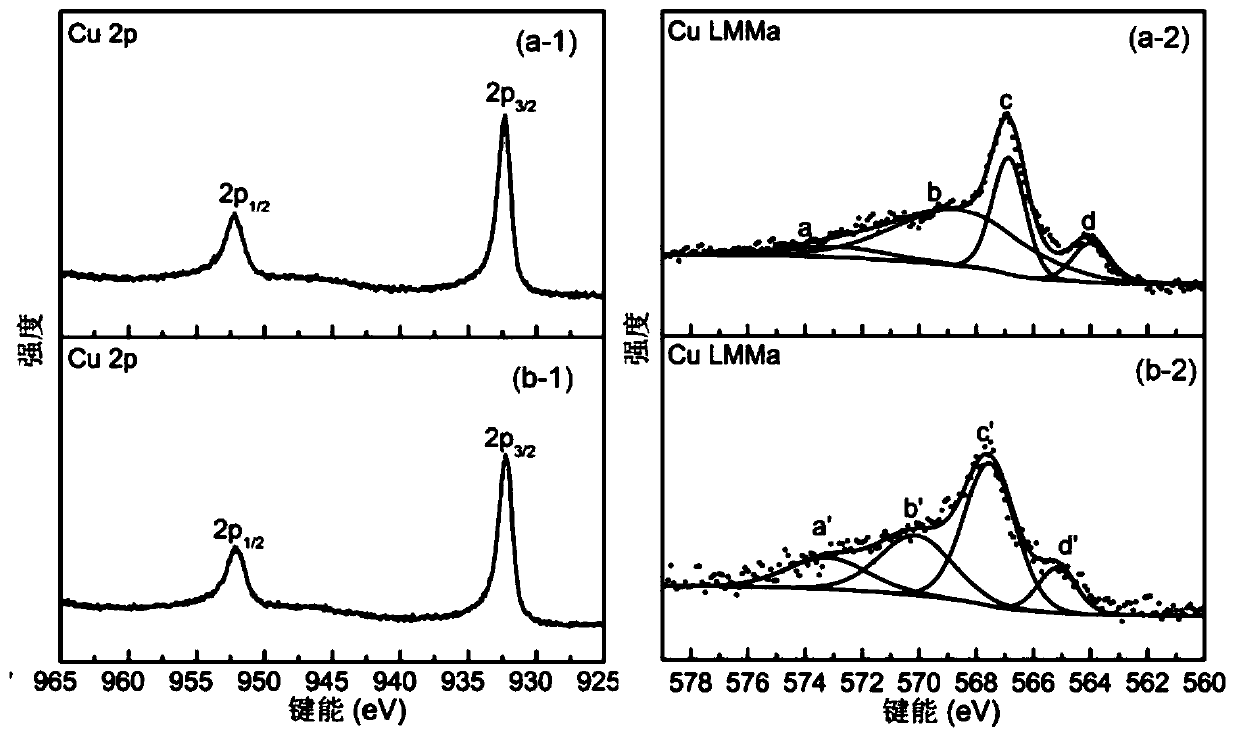

[0081] Such as image 3 The XPS of (b-1) and the Auger spectrum of 3 (b-2) show that the Cu element on the surface of the coating is +1 valence. Further observation of the cross-sectional morphology of...

Embodiment 3

[0085] Prepare hard ceramic coating according to the method described in Example 1;

[0086] Wherein, the specific parameters in step (3) are: Cu target power density: 3.24W / cm 2 ; Zr 58 Cu 30 al 12 Target power density: 3.65W / cm 2 ; The flow ratio of nitrogen to argon is N 2 : Ar=0.06; substrate bias: -10V; heating temperature: 150°C; coating deposition rate: 30nm / min.

[0087] Structural characterization of the obtained coating: it is found that the composition of the coating obtained in Example 1 is Zr 39.1 Cu 18.0 al 4.8 N 38.1 , showing as figure 1 In the shown two-phase composite structure of amorphous ZrN crystal grains, the size of ZrN grains is 10-15 nm, and the thickness of the amorphous phase between two adjacent ZrN grains is 10-30 nm.

[0088] XPS and Auger spectra show that the Cu element on the surface of the coating is +1 valence. The cross-sectional morphology of the coating was further observed with an electron microscope. There were no columnar cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com