Polyester yarn cleaning device

A cleaning device and polyester yarn technology, which is applied in the direction of artificial filament cleaning/drying, textiles and papermaking, and complete sets of equipment for the production of artificial threads. To achieve the effect of enhancing the utilization rate of water resources, improving the comprehensiveness of cleaning, and improving the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The 123 of the present invention will be further described in detail through specific examples below.

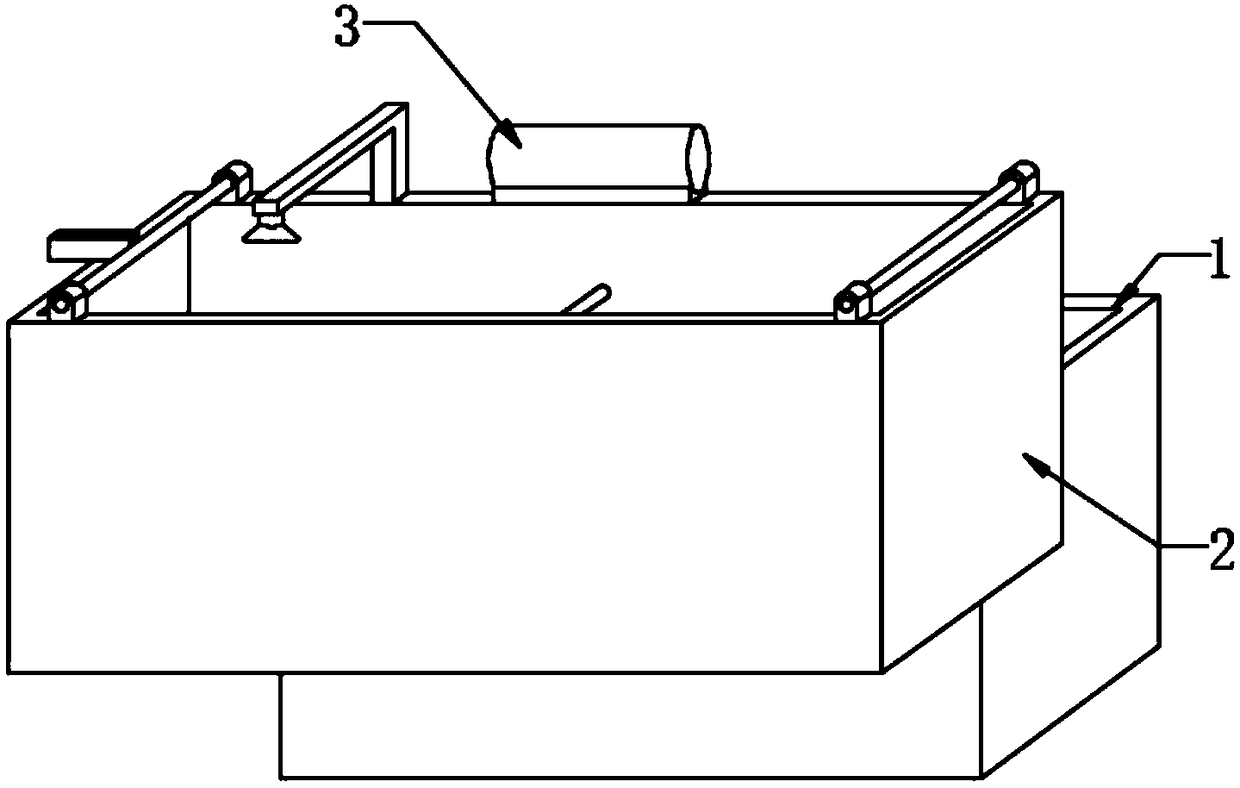

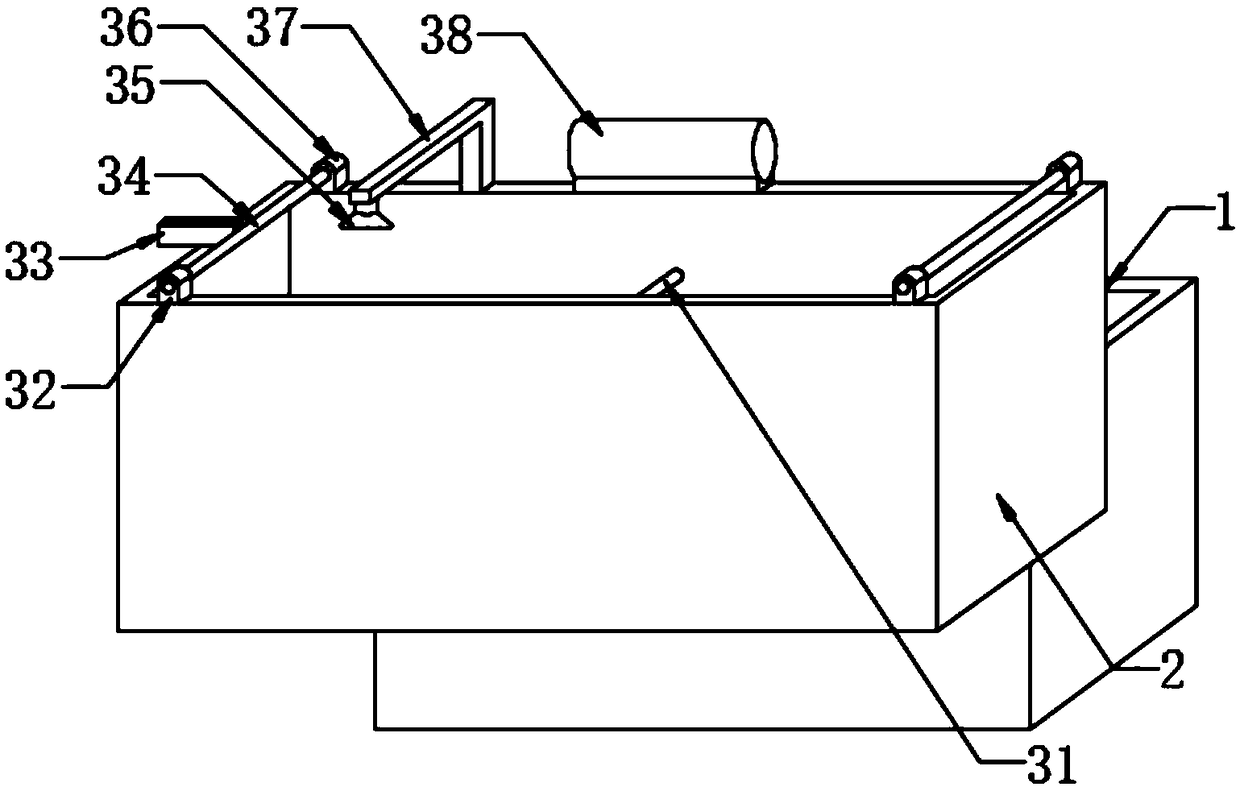

[0018] see Figure 1-Figure 3 , the present invention provides a technical solution: a polyester yarn cleaning device, including a clean water pool 1, a cleaning pool 2 and a cleaning mechanism 3, the clean water pool 1 is arranged on the rear end surface of the cleaning pool 2, and a cleaning mechanism 3 is arranged on the upper side of the cleaning pool 2 .

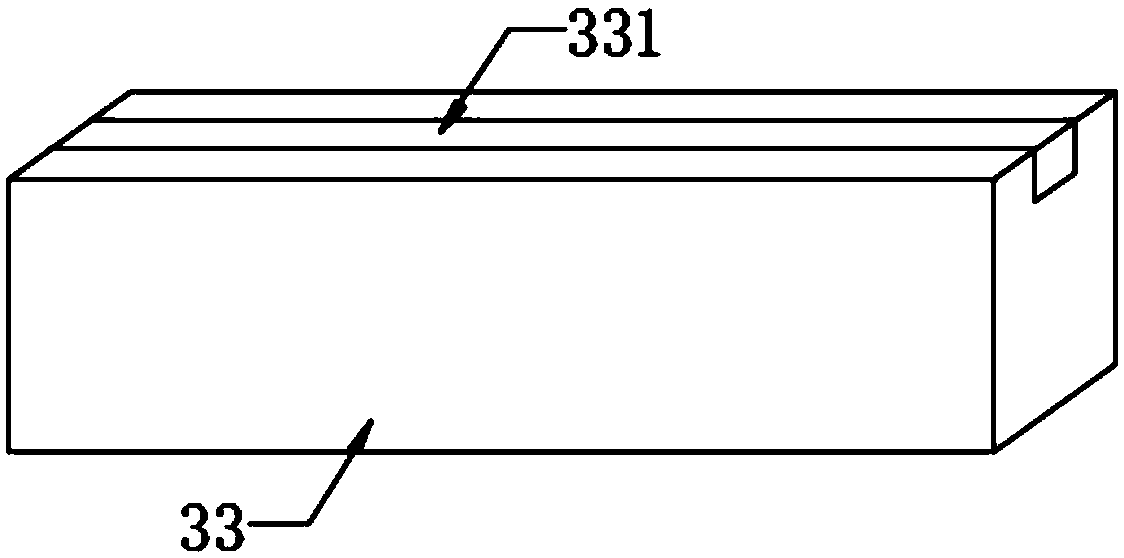

[0019] The cleaning mechanism 3 includes a limit rod 31, a first fixed seat 32, a cleaning block 33, a transmission roller 34, a nozzle 35, a second fixed seat 36, a fixed frame 37 and a circulation pump 38, and the limit rod 31 is installed inside the cleaning tank 2 In the middle position, the first fixed seat 32 is installed on the front side of the upper end of the cleaning tank 2, the second fixed seat 36 is installed on the rear side of the upper end surface of the cleaning tank 2, and the inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com