Precast rubber concrete vibration-absorbing track plate

A technology of rubber concrete and track slab is applied in the field of track slab to achieve the effects of easy production and excellent vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

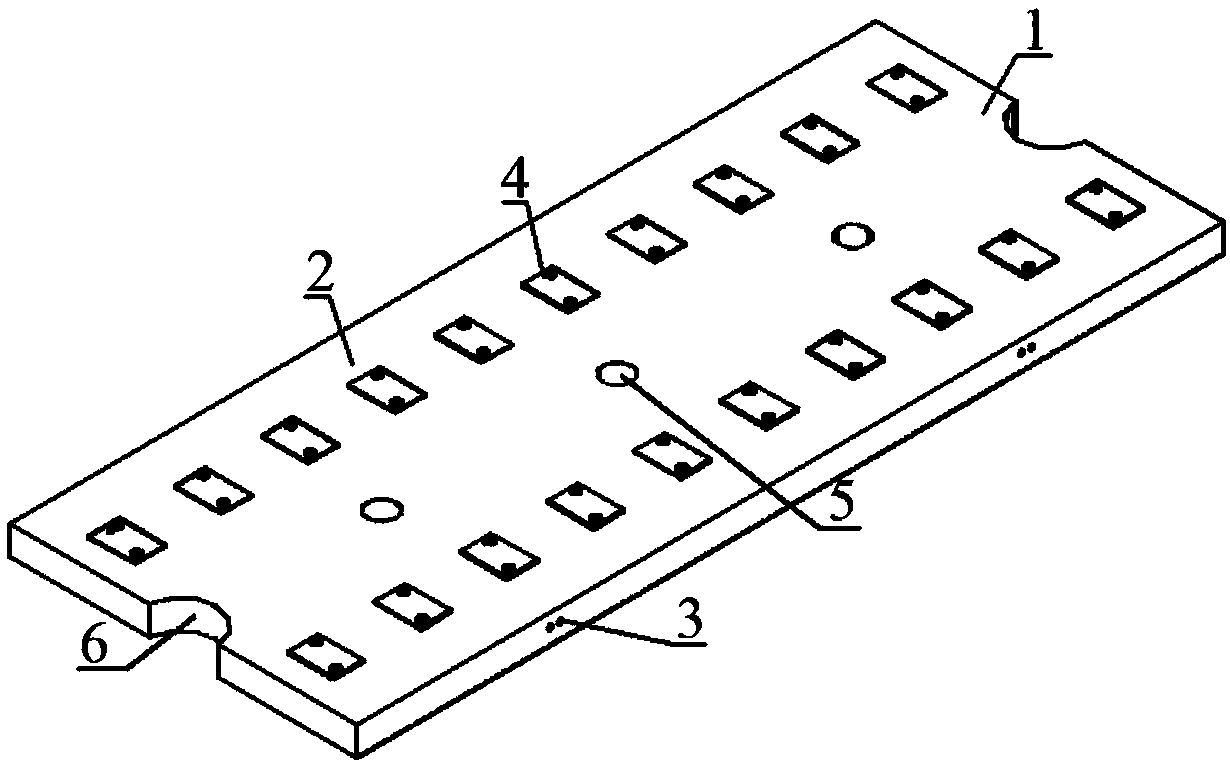

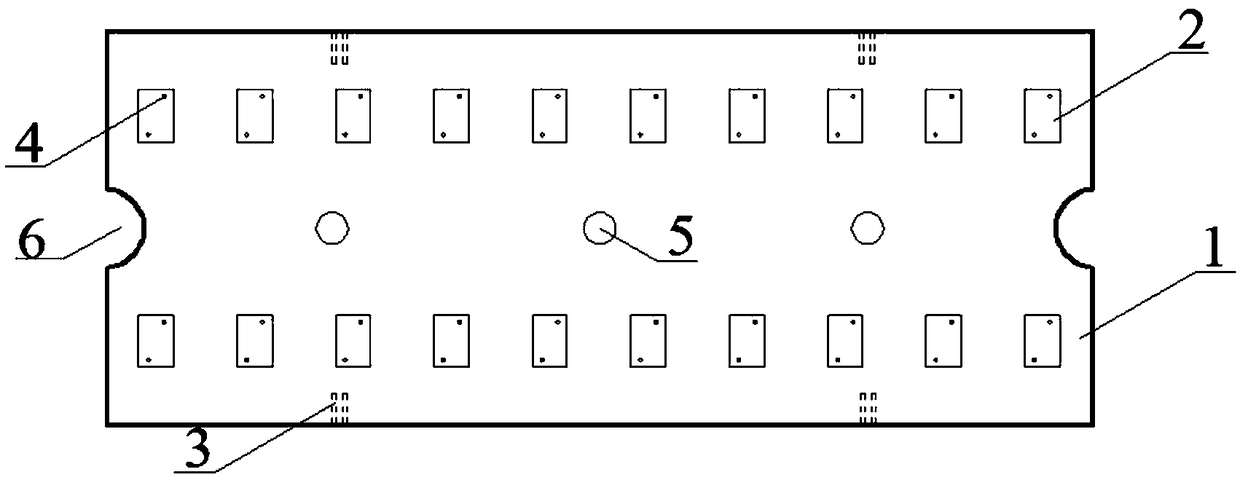

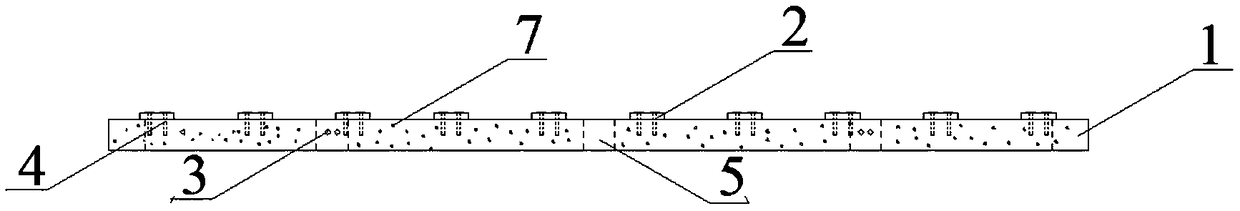

[0033] Prefabricated rubber concrete track slabs such as figure 1 , 2 , 3 and 4, including track slab main body 1 and rail support platform 2, lifting hole 3 is set on the side of the track slab main body, insulating sleeve 4 is set on the track slab support platform, and the track slab is vertically arranged through the grouting hole 5. Limiting holes 6 are provided at the end of the track plate to transfer the track load and facilitate the fixing of the track plate.

[0034] The main body of the track slab is prefabricated by rubber concrete mixed with rubber particles 7. In this embodiment, the rubber particles in the rubber concrete account for 8% by mass.

[0035] The length of the main body of the track slab is restricted by conditions such as transportation, construction, and maintenance. The preferred length is 6.25m, but it can also be adjusted according to engineering needs.

[0036] Through the grouting treatment through the grouting hole 5, the prefabricated rubb...

Embodiment 2

[0038] Such as figure 1 , 2 , 3, 4, 5 and 6, the prefabricated rubber concrete track slab includes a track slab main body 1 and a rail support platform 2, the side of the track slab main body is provided with a lifting hole 3, and the rail support platform is provided with an insulating sleeve 4. The limit hole 6 is provided at the end of the track plate, which can transmit the track load and facilitate the fixing and positioning of the track plate.

[0039] The main body of the track slab is prefabricated by rubber concrete mixed with rubber particles 7 . In this embodiment, the rubber particles in the rubber concrete account for 5% by mass. It has the characteristics of elastic adjustment and its own vibration reduction characteristics.

[0040] The length of the main body of the track slab is restricted by conditions such as transportation, construction, and maintenance. The preferred length is 6.25m, but it can also be customized according to engineering needs.

[0041]...

Embodiment 3

[0043] Such as figure 1 , 2 , 3, 4, 7 and 8, the prefabricated rubber concrete track slab includes a track slab main body 1 and a rail support platform 2, the side of the track slab main body is provided with a lifting hole 3, and the rail support platform is provided with an insulating sleeve 4. Limiting holes 6 are provided at the end of the track plate to transfer the track load and facilitate the fixing and positioning of the track plate.

[0044] The main body of the track slab is prefabricated by rubber concrete mixed with rubber particles 7 . In this embodiment, the rubber particles in the rubber concrete account for 5% by mass. It has the characteristics of elastic adjustment and its own vibration reduction characteristics.

[0045] The length of the main body of the track slab is restricted by conditions such as transportation, construction, and maintenance. The preferred length is 6.25m, but it can also be customized according to engineering needs.

[0046] Suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com