Selective laser melting additive manufacturing method and additive manufacturing device for manganese-copper alloy forming

A laser selective melting, manganese-copper alloy technology, applied in the field of additive manufacturing, can solve the problems of difficult forming process of additive manufacturing, easy volatilization of manganese to form holes and cracks, no forming quality, etc., to improve mechanical properties and damping performance, The effect of comprehensive mechanical properties and damping performance, good vibration reduction and damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

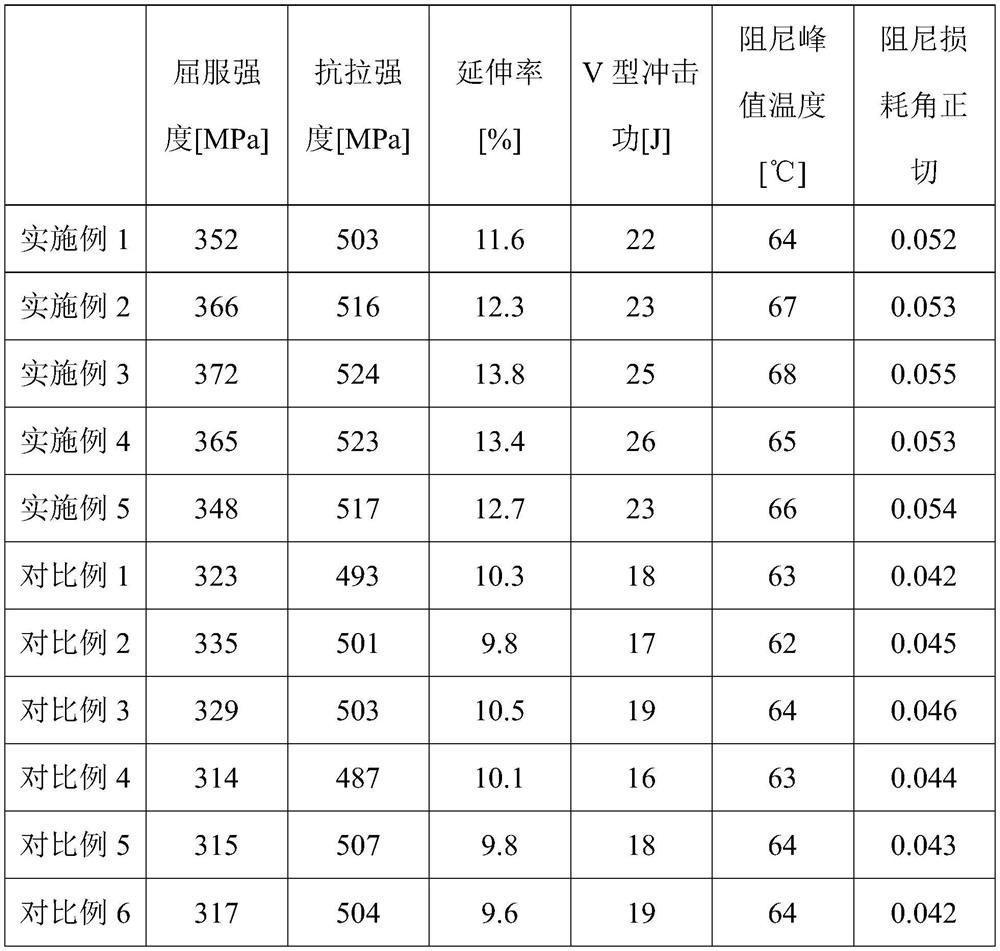

[0074] The injector damping ring of M2052 manganese-copper alloy is prepared by using the additive manufacturing device provided in the specific embodiment, and the content of each element in the M2052 manganin-copper alloy used is shown in the following table:

[0075] element mn Cu Ni Fe Impurities Content [wt%] 63.15 26.85 5.2 3.8 margin

[0076] The specific additive manufacturing process includes the following steps:

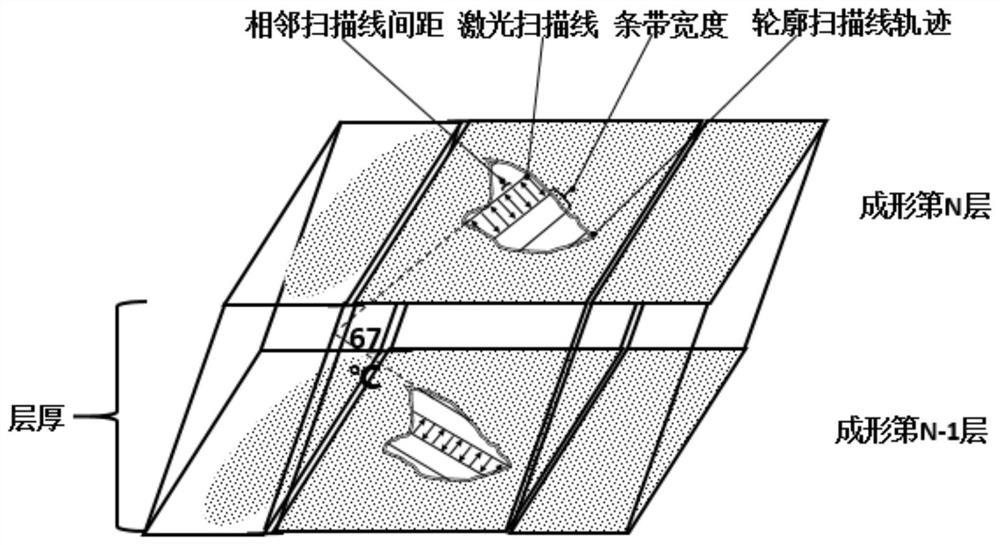

[0077] (1) Build a three-dimensional structural model of the target part, add an auxiliary support structure on the outer surface of the model, perform two-dimensional slice layering on the model, and import the model slice layer file into the additive manufacturing software to generate a slice scanning path;

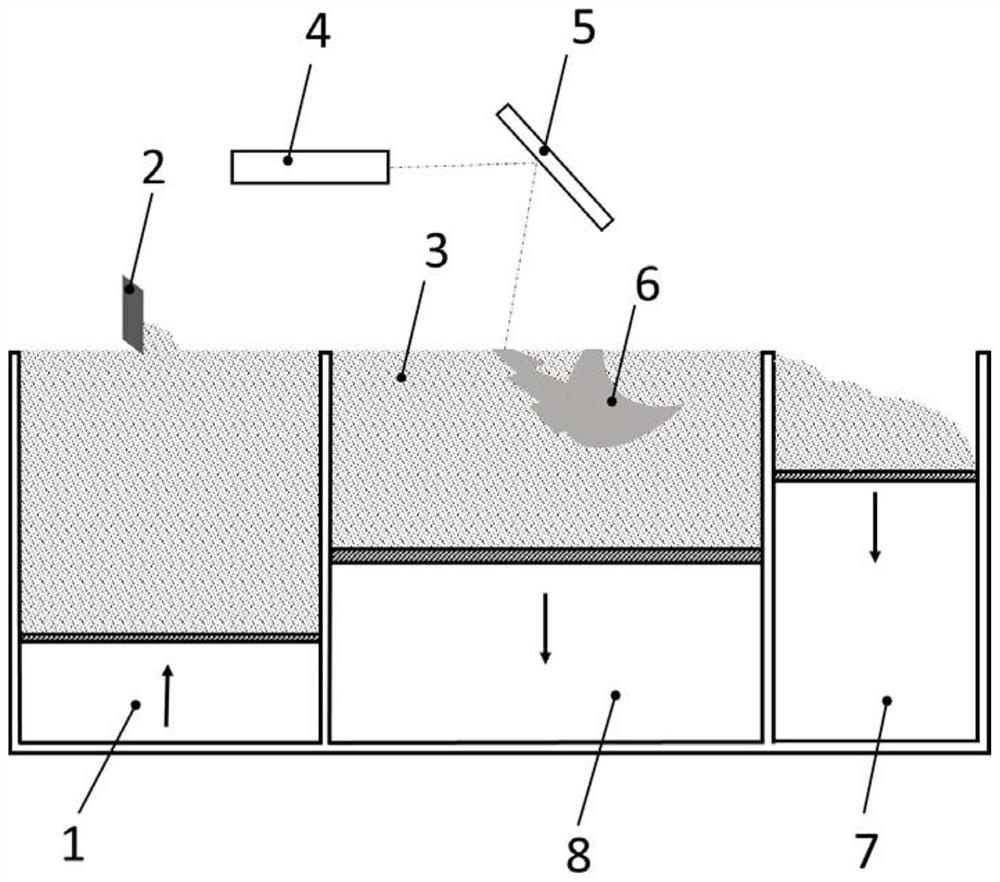

[0078] (2) The vertically movable partition in the powder supply cabin 1 moves up, and the M2052 manganese-copper alloy powder 3 stored in the powder supply cabin 1 is pushed out of the powder supply cabin 1. The av...

Embodiment 2

[0086] The injector damping ring of M2052 manganese-copper alloy is prepared by using the additive manufacturing device provided in the specific embodiment, and the content of each element in the M2052 manganin-copper alloy used is shown in the following table:

[0087] element mn Cu Ni Fe Impurities Content [wt%] 65.28 25.36 5.34 3.4 margin

[0088] The specific additive manufacturing process includes the following steps:

[0089] (1) Build a three-dimensional structural model of the target part, add an auxiliary support structure on the outer surface of the model, perform two-dimensional slice layering on the model, and import the model slice layer file into the additive manufacturing software to generate a slice scanning path;

[0090] (2) The vertically movable partition in the powder supply cabin 1 moves up, and the M2052 manganese-copper alloy powder 3 stored in the powder supply cabin 1 is pushed out of the powder supply cabin 1. The a...

Embodiment 3

[0098] The additive manufacturing device provided by the specific embodiment is used to prepare the submarine propeller of the M2052 manganese-copper alloy. The content of each element in the M2052 manganese-copper alloy used is shown in the following table:

[0099] element mn Cu Ni Fe Impurities Content [wt%] 71.32 20.45 5.2 2 margin

[0100] The specific additive manufacturing process includes the following steps:

[0101] (1) Build a three-dimensional structural model of the target part, add an auxiliary support structure on the outer surface of the model, perform two-dimensional slice layering on the model, and import the model slice layer file into the additive manufacturing software to generate a slice scanning path;

[0102] (2) The vertically movable partition in the powder supply cabin 1 moves up, and the M2052 manganese-copper alloy powder 3 stored in the powder supply cabin 1 is pushed out of the powder supply cabin 1. The average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com