Gear box oil pump having oil unloading structure, and gear box

A gearbox and oil pump technology, applied in the field of machinery, can solve the problems of increased oil leakage, deformation of the oil pump casing and diaphragm, etc., and achieves the effect of reducing the axial force and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

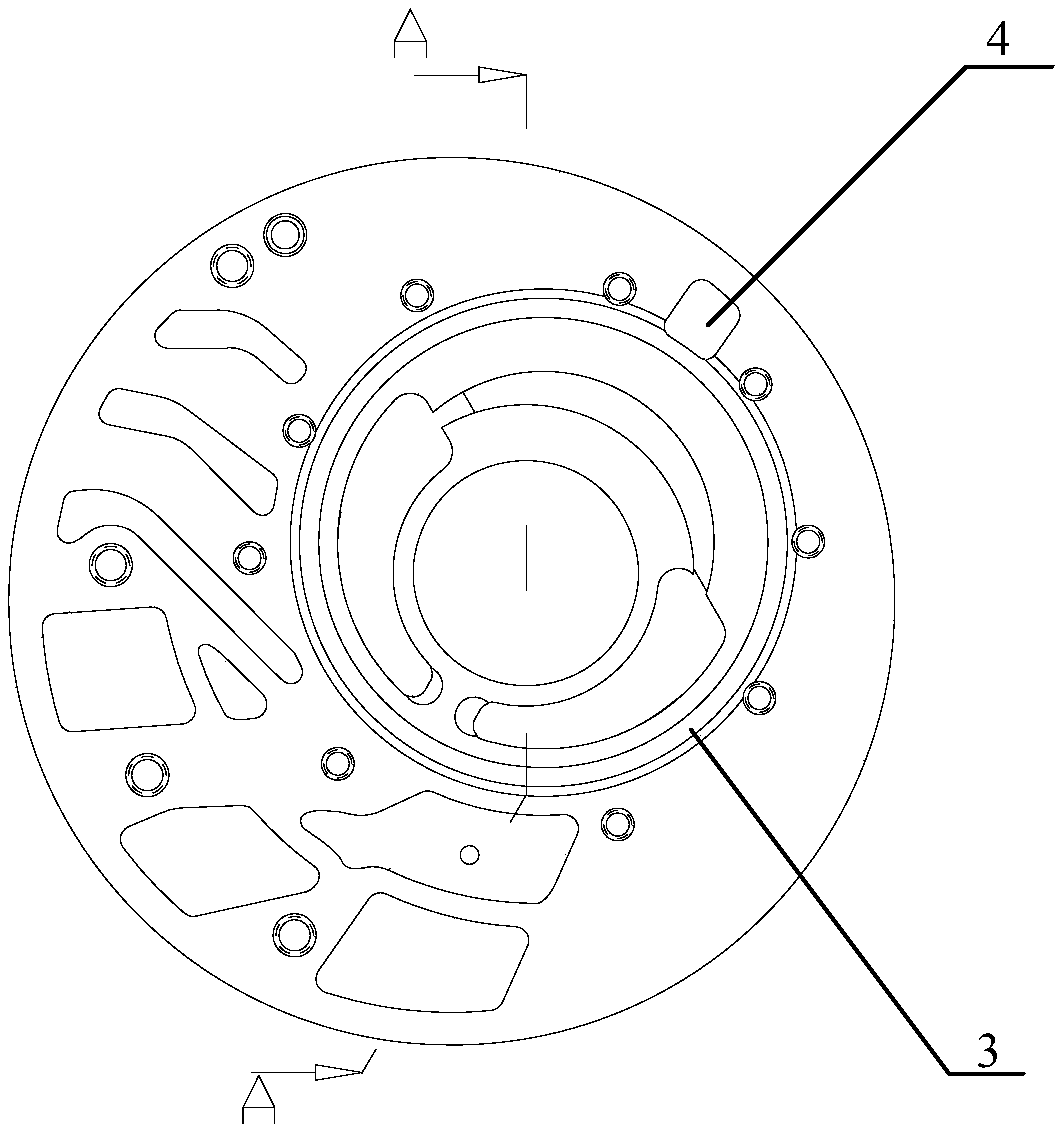

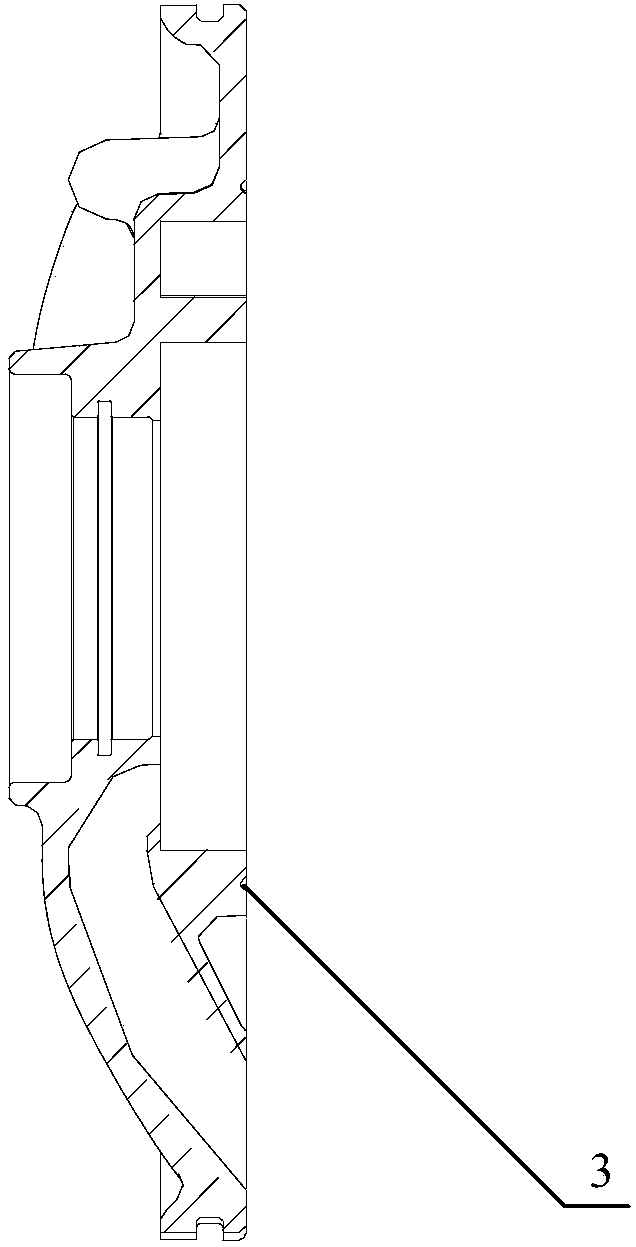

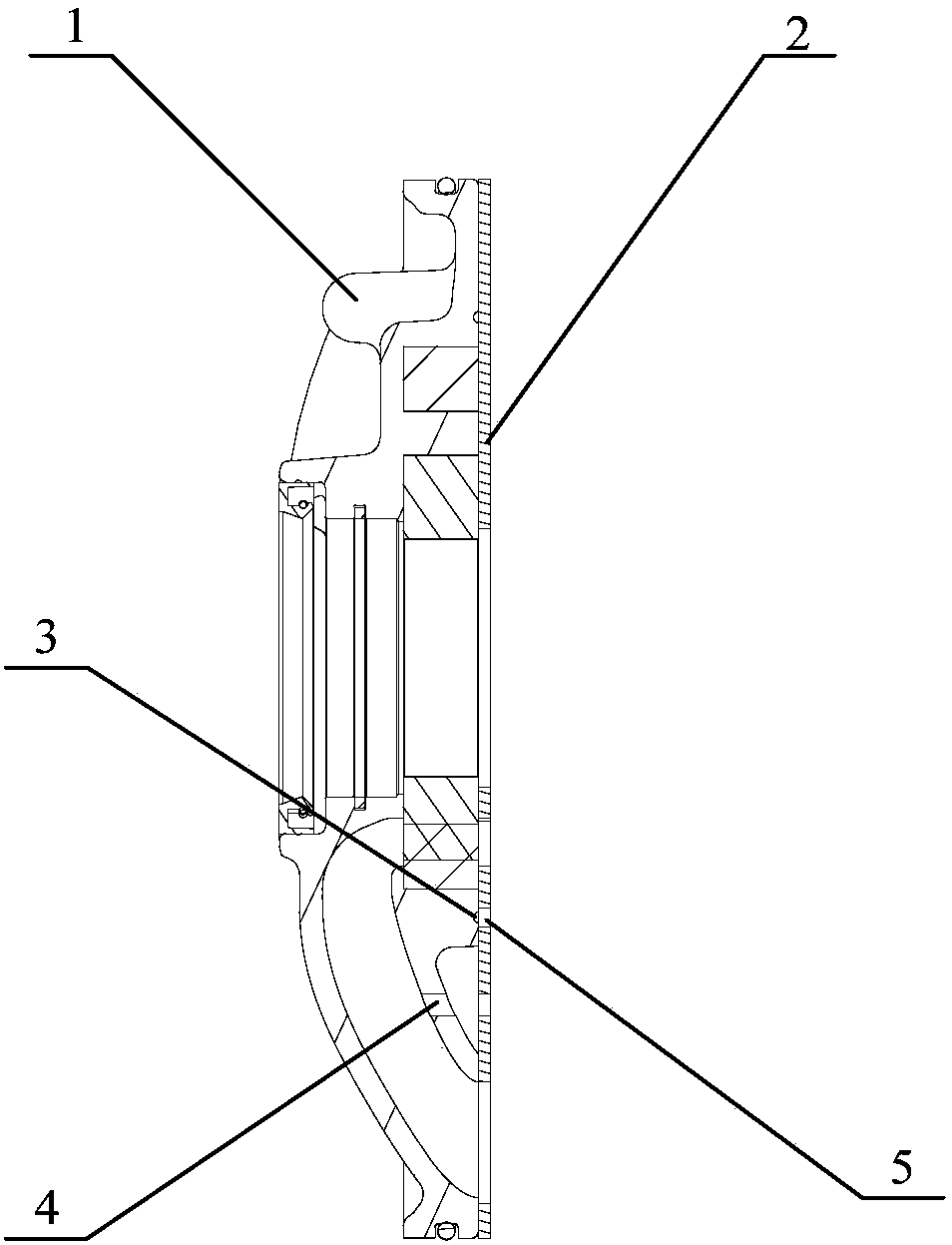

[0025] figure 1 A schematic front view of a casing of a transmission oil pump with an oil unloading structure provided in Embodiment 1 of the present invention. figure 2 for figure 1 A-A cross-sectional schematic diagram in. image 3 It is a schematic structural diagram of a transmission oil pump with an oil unloading structure provided in Embodiment 1 of the present invention. like Figure 1 to Figure 3 As shown, the gearbox oil pump with oil unloading structure provided in this embodiment includes: the casing 1 and the partition 2 of the oil pump fixedly connected, and the oil pump rotor arranged in the cavity surrounded by the casing 1 and the partition 2 (not shown in the figure), the housing 1 is provided with an annular groove 3 and an oil discharge passage 4, the annular groove 3 is located on the outside of the oil pump rotor, and the annular groove 3 is arranged on the joint between the housing 1 and the partition plate 2 On the surface; the unloading oil channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com