Structure capable of improving stability of underwater vehicle floating bag safety valve

A technology for underwater vehicles and safety valves, which is applied in the field of safety valves, can solve problems such as poor working stability of safety valves, and achieve the effects of improved reliability indicators, stable work, and improved safety and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

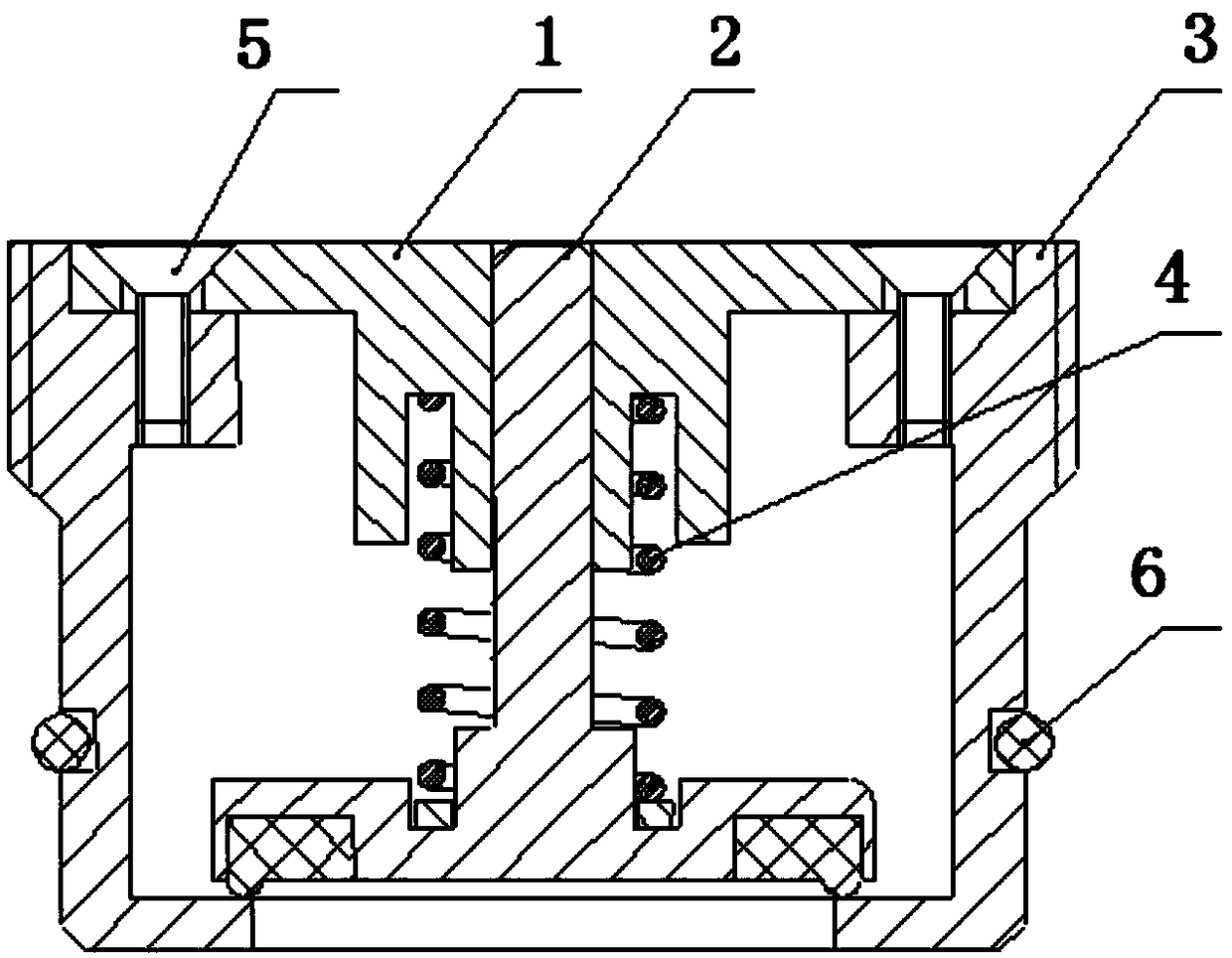

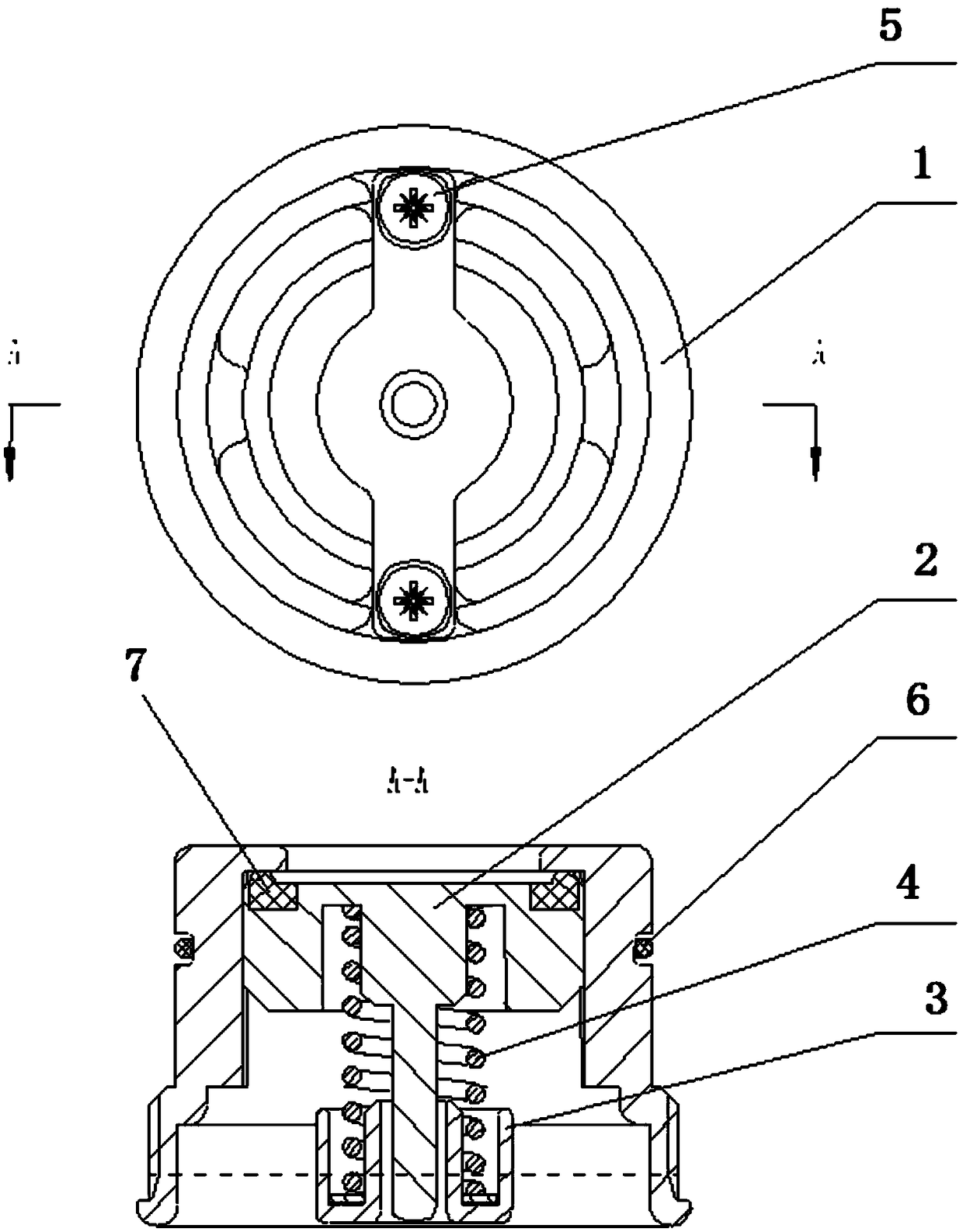

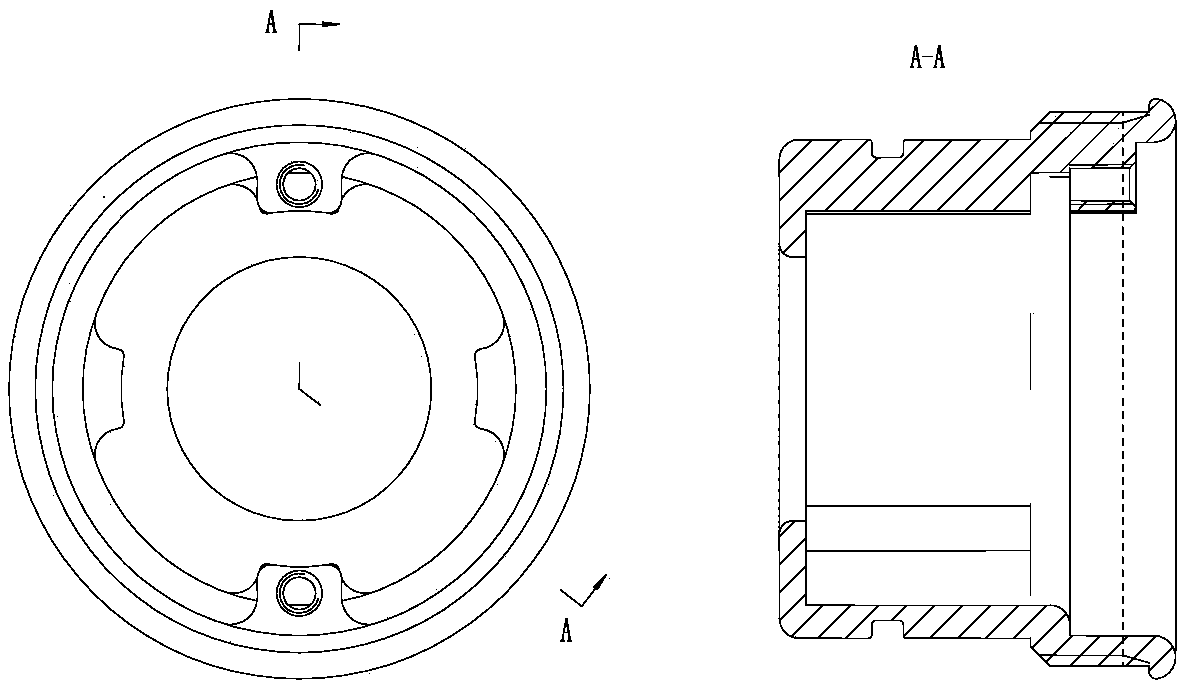

[0018] see figure 2 — Figure 5 , The present invention includes a valve body 1, a valve stem 2, and a guide sleeve 3. The valve body 1 is cylindrical, one end of the outer surface of the cylinder is a mounting thread, the other end is a sealing mating surface, and an O-shaped sealing ring installation groove is designed. One end of the valve body 1 is designed with two mounting bosses with threaded holes, and the other end is a For the inlet throat diameter of the safety valve, there are four guide rails inside the valve body 1. The guide rails are in the shape of a cross. The height of the guide rails is greater than the maximum distance that the valve stem 2 can move in the safety valve. The tolerance of the guide rail and the valve stem 2 is H9. The valve stem 2 is in the shape of a stepped cylinder, and the sealing surface in contact with the valve body 1 is vulcanized with rubber. In order to ensure that the valve stem 2 and the guide rail of the valve body 1 are not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com