Chip comprehensive detection device

A kind of testing equipment and comprehensive technology, applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as missed detection, troublesome operation, errors, etc., and achieve simple and convenient operation, improved efficiency, and high detection quality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

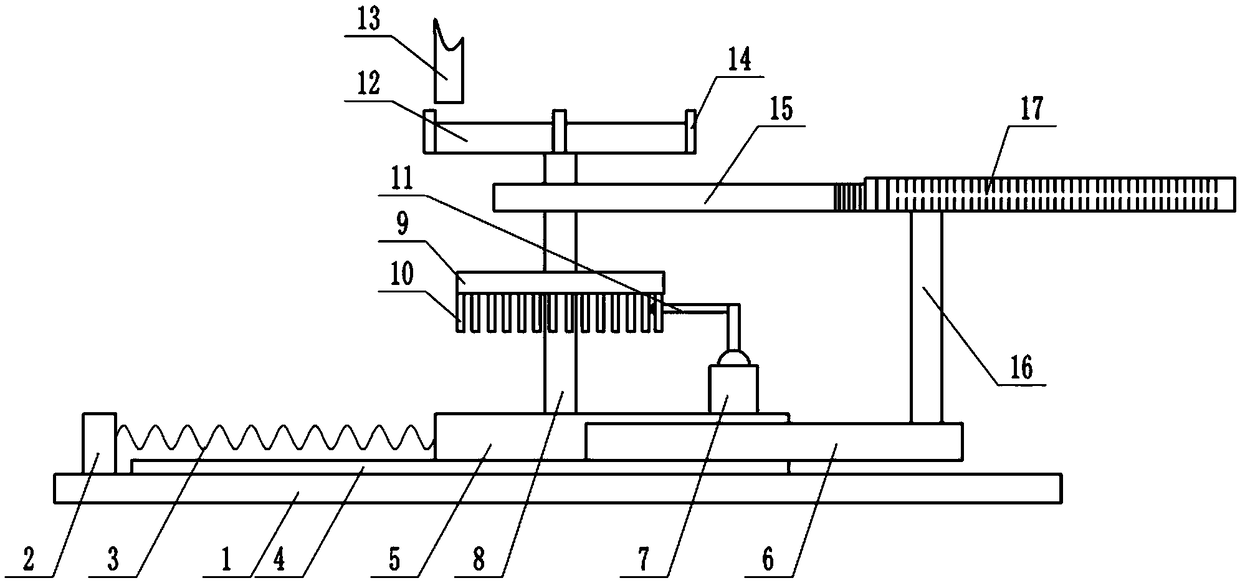

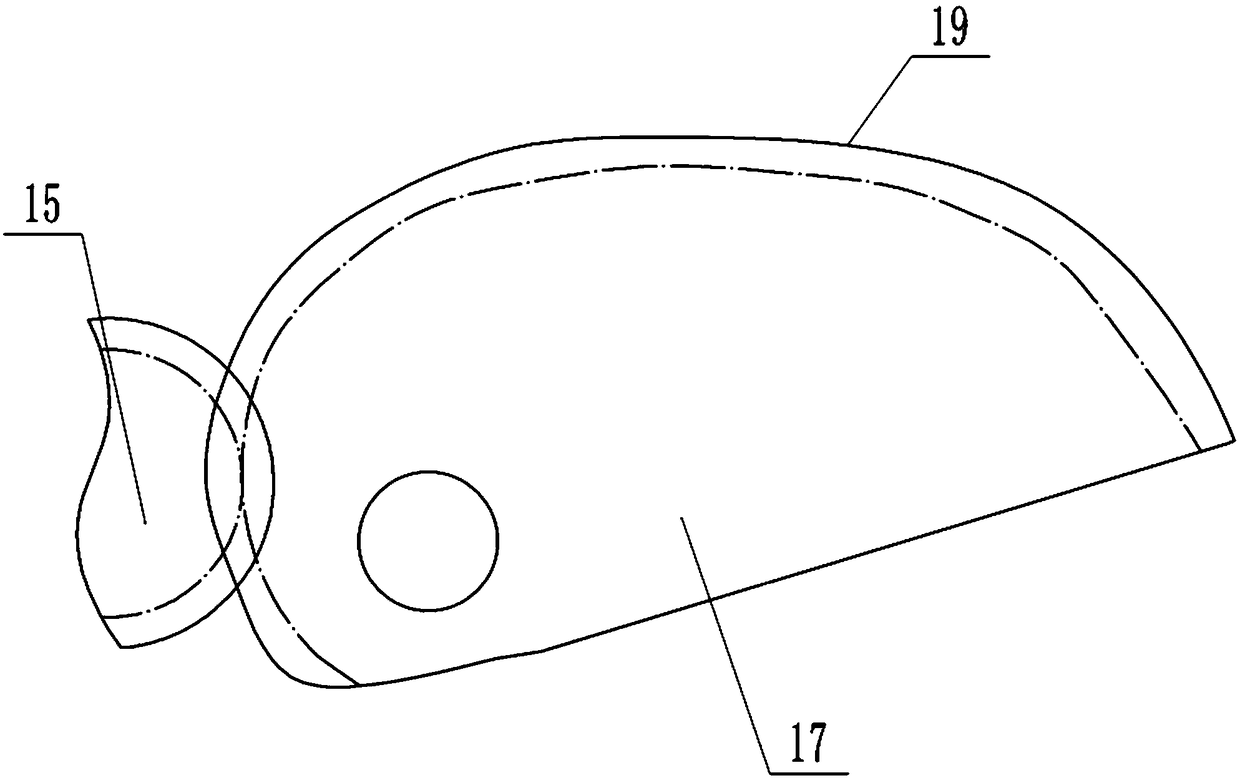

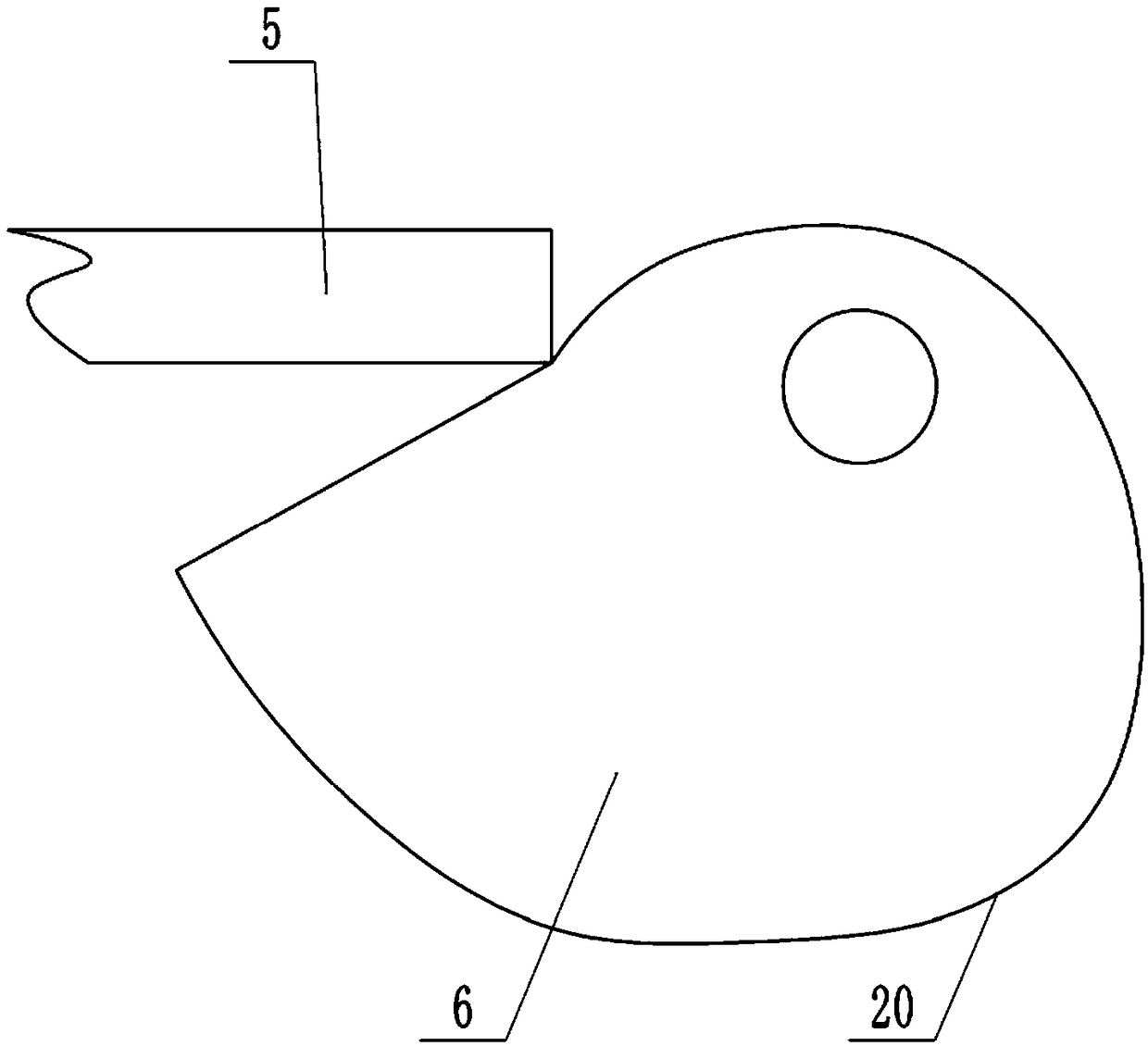

[0020] The reference signs in the accompanying drawings of the description include: fixed table 1, fixed block 2, compression spring 3, convex strip 4, sliding seat 5, cam 6, motor 7, rotating shaft 8, rotating disc 9, first driving lever 10, second Two driving rods 11, carrying platform 12, objective lens 13, limit block 14, first sector gear 15, connecting shaft 16, second sector gear 17, first circular path 18, tooth part 19, offset part 20, second annular Path 21.

[0021] The embodiment is basically as attached Figure 1-Figure 5 Shown: chip comprehensive inspection equipment, including frame, is provided with fixed platform 1 on the frame, is provided with microscope (not shown in the figure) and is positioned at the circular bearing platform 12 below the objective lens 13 of microscope above fixed platform 1 The carrier table 12 is used to place the wafer, and the carrier ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com