Tea fermentation barrel

A tea fermentation and barrel technology, applied in the field of tea fermentation barrels, can solve the problems of slow fermentation speed, unsuitable production methods of many varieties and small batches, etc., and achieves the effects of simple structure, improved production efficiency and quality, and process saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

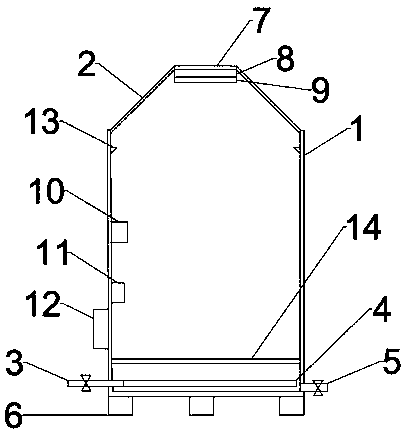

[0017] A tea fermentation barrel is characterized in that it comprises a barrel body 1, a cover 2, an air inlet pipe 3 with a valve, an air outlet pipe 4, a drain pipe 5 with a valve, a leg 6 and a sieve plate 14, wherein the leg 6 is installed on the barrel body The outer side of the bottom surface of 1 is symmetrically distributed, the intake pipe 3 is installed on the bottom side of the barrel body 1 and one end of the intake pipe 3 extends into the interior of the barrel body 1, the air outlet pipe 4 is located at the bottom of the barrel body 1 and is connected with the intake pipe 1, and the drain pipe 5 Installed on the bottom side of the barrel 1, the top of the barrel 1 is also equipped with a cover 2 and the middle of the cover 2 is the air outlet 7, the sieve plate 14 is installed above the air outlet pipe 4 and the edge of the sieve plate 14 is in contact with the inside of the barrel 1.

Embodiment 2

[0019] A tea fermentation barrel is characterized in that it comprises a barrel body 1, a cover 2, an air inlet pipe 3 with a valve, an air outlet pipe 4, a drain pipe 5 with a valve, a leg 6 and a sieve plate 14, wherein the leg 6 is installed on the barrel body The outer side of the bottom surface of 1 is symmetrically distributed, the intake pipe 3 is installed on the bottom side of the barrel body 1 and one end of the intake pipe 3 extends into the interior of the barrel body 1, the air outlet pipe 4 is located at the bottom of the barrel body 1 and is connected with the intake pipe 1, and the drain pipe 5 Installed on the bottom side of the barrel 1, the top of the barrel 1 is also equipped with a cover 2 and the middle of the cover 2 is the air outlet 7, the sieve plate 14 is installed above the air outlet pipe 4 and the edge of the sieve plate 14 is in contact with the inside of the barrel 1.

[0020] The air outlet pipe 4 is an annular porous pipe.

Embodiment 3

[0022] A tea fermentation barrel is characterized in that it comprises a barrel body 1, a cover 2, an air inlet pipe 3 with a valve, an air outlet pipe 4, a drain pipe 5 with a valve, a leg 6 and a sieve plate 14, wherein the leg 6 is installed on the barrel body The outer side of the bottom surface of 1 is symmetrically distributed, the intake pipe 3 is installed on the bottom side of the barrel body 1 and one end of the intake pipe 3 extends into the interior of the barrel body 1, the air outlet pipe 4 is located at the bottom of the barrel body 1 and is connected with the intake pipe 1, and the drain pipe 5 Installed on the bottom side of the barrel 1, the top of the barrel 1 is also equipped with a cover 2 and the middle of the cover 2 is the air outlet 7, the sieve plate 14 is installed above the air outlet pipe 4 and the edge of the sieve plate 14 is in contact with the inside of the barrel 1.

[0023] The air outlet pipe 4 is an annular porous pipe.

[0024] An air extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com