Vibration motor vibration foam pad shock absorption fluidized bed ion exchange water treatment device

A technology of ion-exchanged water and vibration motor, which is applied in the field of chemical machinery, can solve the problems of insufficient ion exchange, short contact time between resin and liquid phase, etc., and achieve the effects of convenient selection, good shock absorption effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing, the present invention is described in further detail.

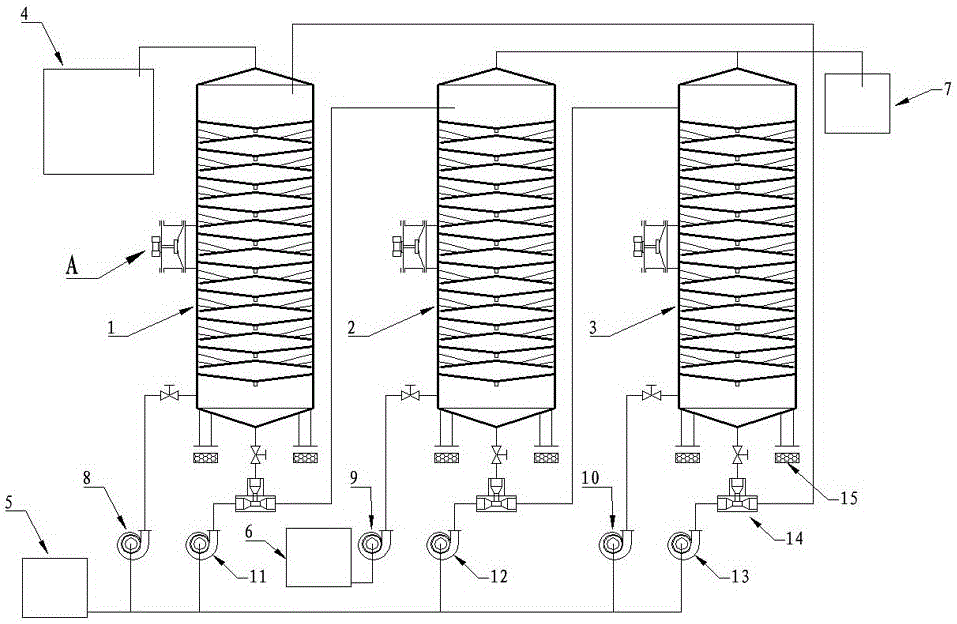

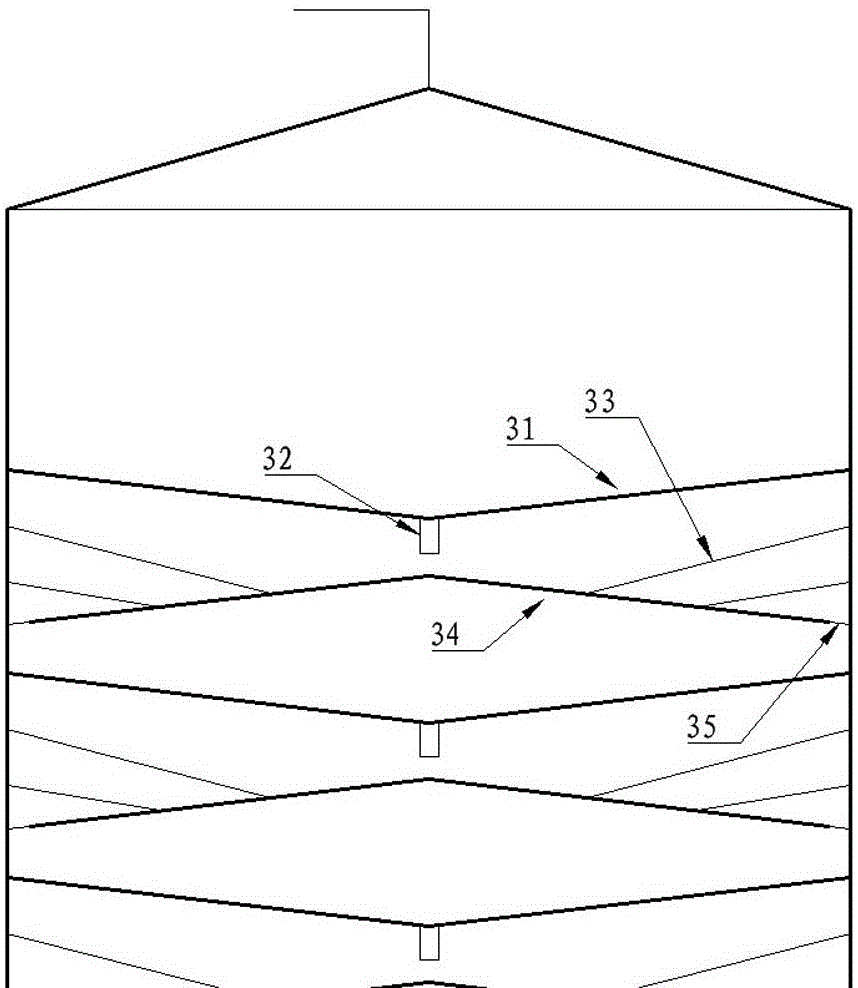

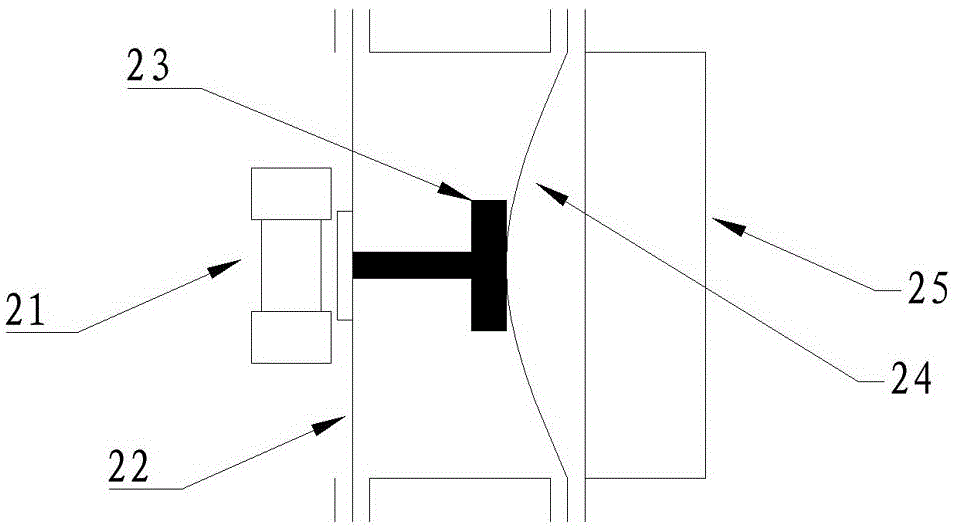

[0021] Such as figure 1 , figure 2 and image 3 The vibrating motor, vibrating foam pad and shock-absorbing fluidized bed ion exchange water treatment device shown include soft water pool 4, raw water pool 5, brine pool 6, waste water pool 7, softening tower 1, regeneration tower 2, washing tower 3, softening tower 1. Both the regeneration tower 2 and the washing tower 3 are repeatedly provided with a tapered funnel screen surface 31 and a bucket hat screen surface 34. The two form a multi-layer support plate for resin dispersion, and water is used as a medium to transmit vibration to realize the layer-by-layer drop and flow of the resin. Dispersion; a central drop pipe 32 is provided under the screen surface 31 of the conical funnel to transfer the resin on the screen surface 31 of the conical funnel to the screen surface 34 of the bucket hat, and an elastic ring 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com